- Joined

- Jan 19, 2010

- Messages

- 1,193

- Reaction score

- 41

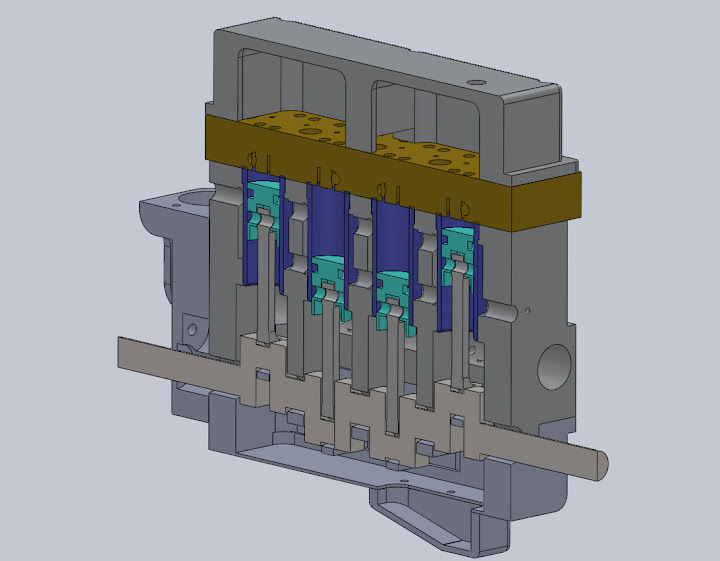

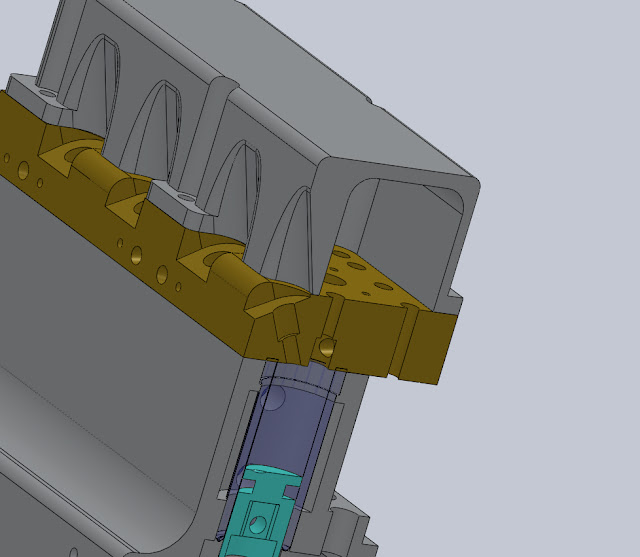

It has been awhile since I posted in this thread. I am about 75% complete with the drawings and am continuing to work on them. I will be posting in this thread when the plans will be available.

After a month or so of computer work I got anxious to do some shop work. I seen a post from CaptainJerry on his mousepower dyno. I really liked the Idea and wanted to implement something for my TI4.

I decided to make it a separate device from the engine, then it could be used on multiple engines in the future, or to gauge changes in the engine, like cam duration and ignition timing and so forth.

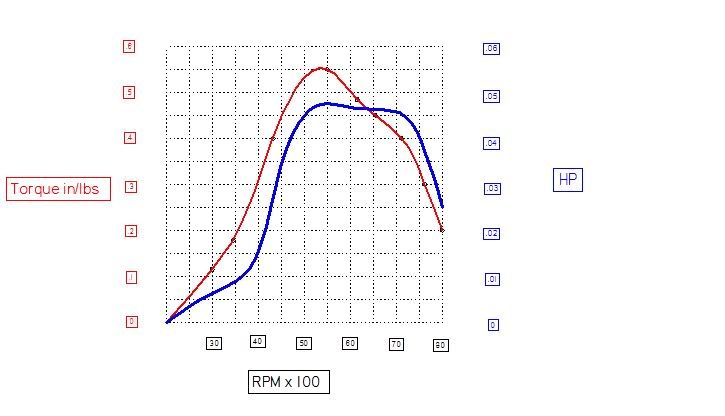

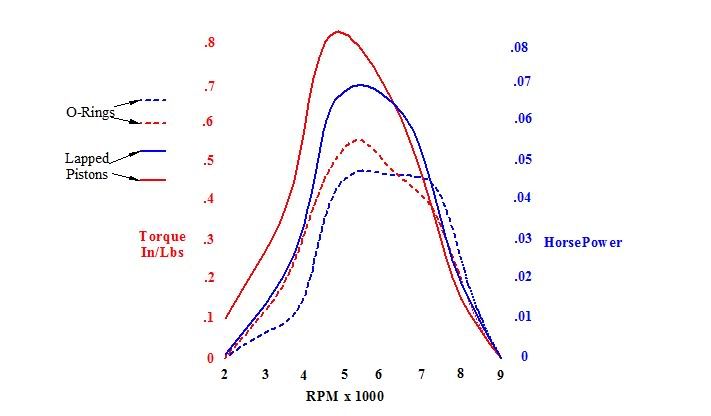

Here is a video of the beginnings of my dyno. I picked up some force gauges of e-bay and this one reads in .01lb increments, with a total of 1lb. I have a prony brake on a 1 inch center, so the gauge reads directly in in/lbs from the driveshaft.

Doing the math and whatnot with RPM and torque I come up with a max reading of .05HP @ 6800 RPM, and .5 in/lbs of torque @ around 5000 rpm. I need to do some more testing to get a larger sample size for an average.

Let me know if I am doing anything wrong, or could do it better. My readings seem small, but than again 1/20th of a horse aint bad for something I made in my basement :big:

[ame]http://www.youtube.com/watch?v=jd3tXuJu1Gs[/ame]

Kel

After a month or so of computer work I got anxious to do some shop work. I seen a post from CaptainJerry on his mousepower dyno. I really liked the Idea and wanted to implement something for my TI4.

I decided to make it a separate device from the engine, then it could be used on multiple engines in the future, or to gauge changes in the engine, like cam duration and ignition timing and so forth.

Here is a video of the beginnings of my dyno. I picked up some force gauges of e-bay and this one reads in .01lb increments, with a total of 1lb. I have a prony brake on a 1 inch center, so the gauge reads directly in in/lbs from the driveshaft.

Doing the math and whatnot with RPM and torque I come up with a max reading of .05HP @ 6800 RPM, and .5 in/lbs of torque @ around 5000 rpm. I need to do some more testing to get a larger sample size for an average.

Let me know if I am doing anything wrong, or could do it better. My readings seem small, but than again 1/20th of a horse aint bad for something I made in my basement :big:

[ame]http://www.youtube.com/watch?v=jd3tXuJu1Gs[/ame]

Kel