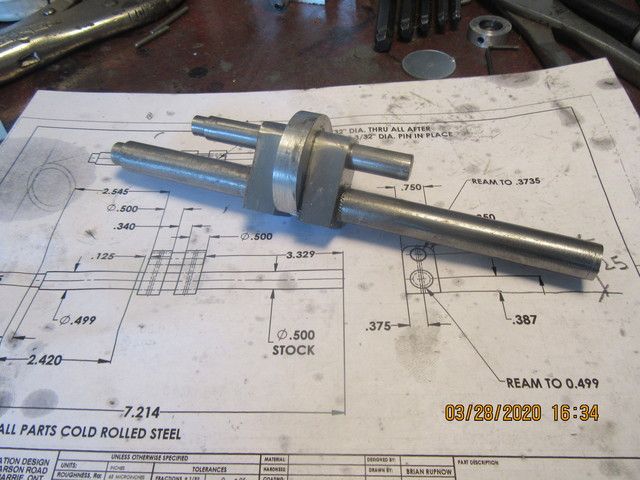

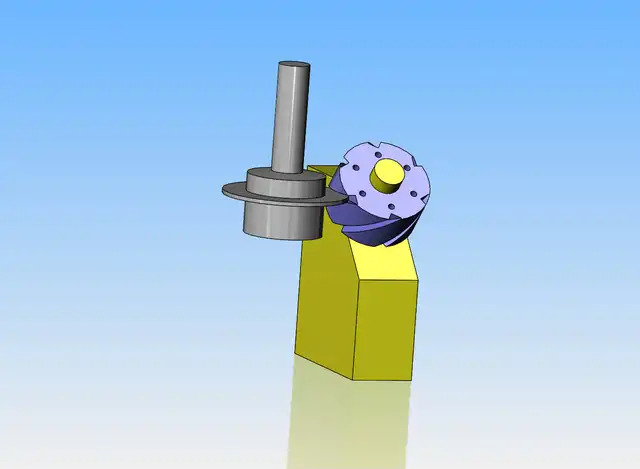

Yesterday my rings came in from Debolt. They look good. They are exactly 0.094" thick. The grooves I cut in my piston with my 0.094" parting off tool are only 0.088" wide. Not sure how that happened, but it should be an easy fix. The rings have a staggered lap joint in them, which I didn't know would be there, but I'm sure they will probably work okay. Some horrible economics are involved with these rings. Debolt charges $8 each USA money for these rings. Change that to Canadian dollars, pay tax on it, then pay for shipping. Ends up costing me $56 Canadian. This morning I machined and installed an ignition cam. I went to make proper pivot shafts for the rocker arms, but I'm having an issue with concentricity. I checked my lathe head-shaft and chuck, and it has 0.003 TIR, same as it had when I bought it. The main chuck will only close down to 0.150", so I'm holding an extra smaller chuck in the main chuck. I'm getting crazy concentricity results and I'm not sure why, but will probably figure it out after posting this. As of today, I've been machining on this engine for 30 days straight. I may soon take a break and start setting up my TIG welder.