a41capt

Well-Known Member

Yes, as I said in the previous post, I ordered a set of two rings from Debolt in USA.

Brian, et. al.,

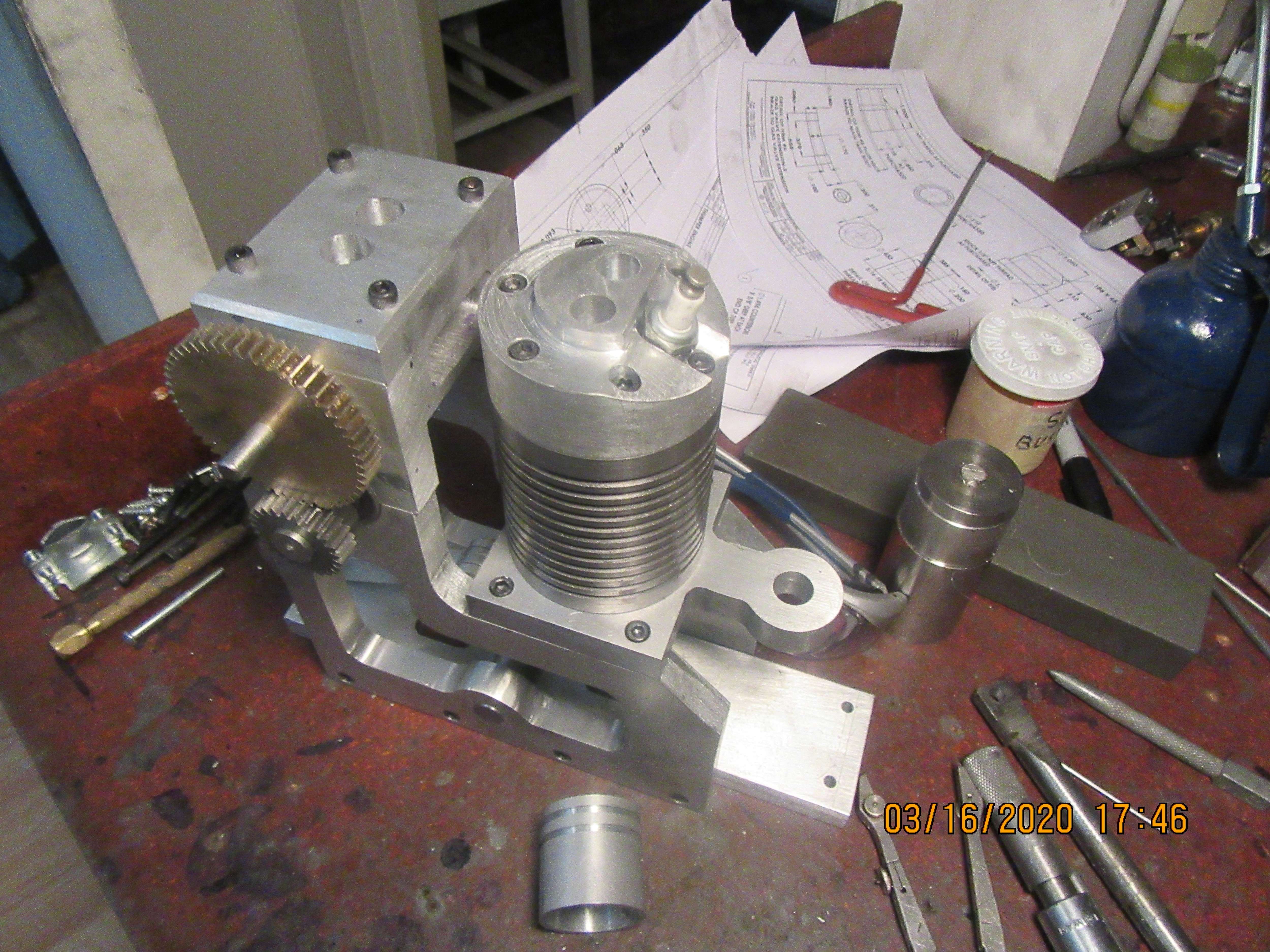

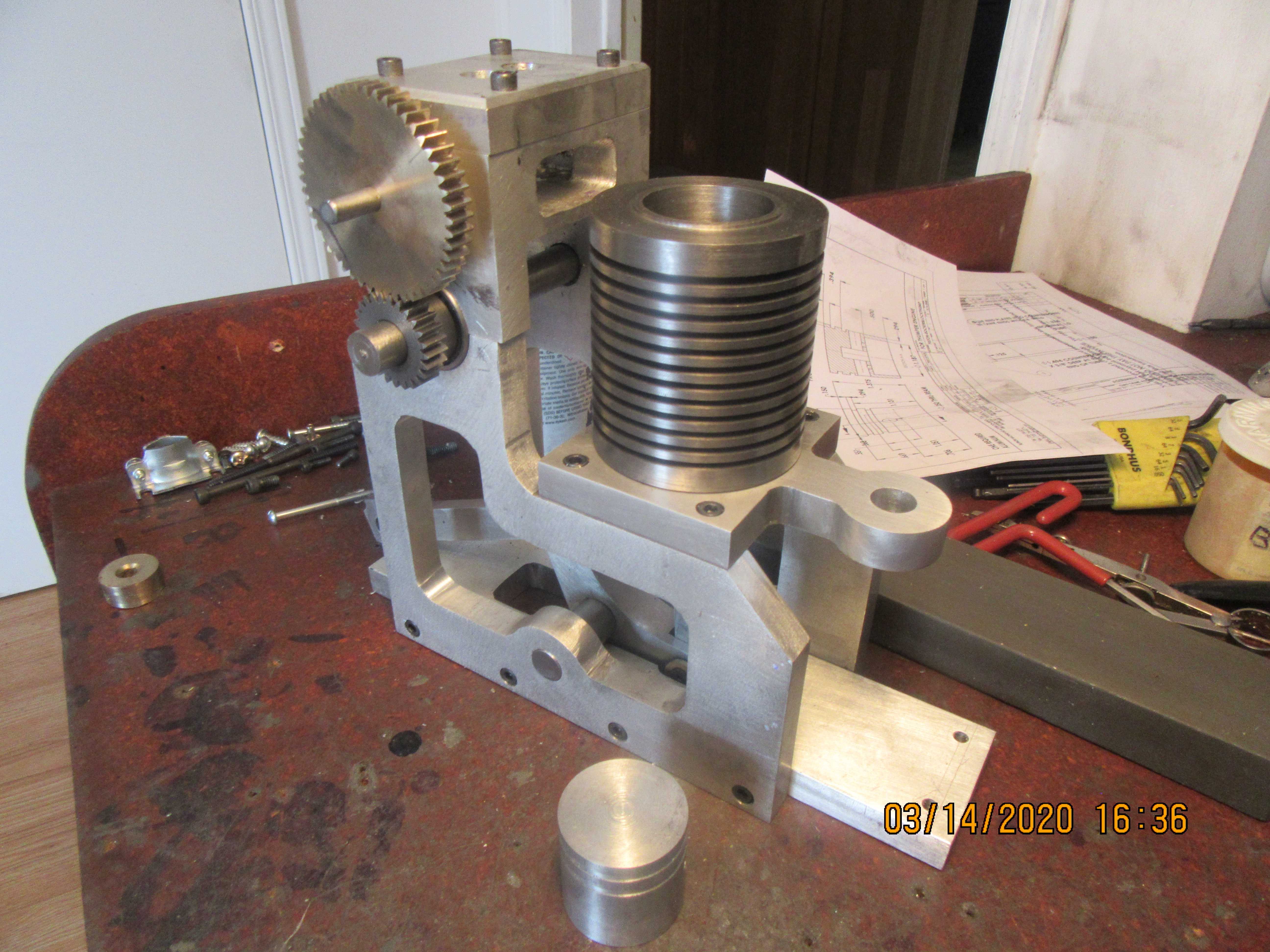

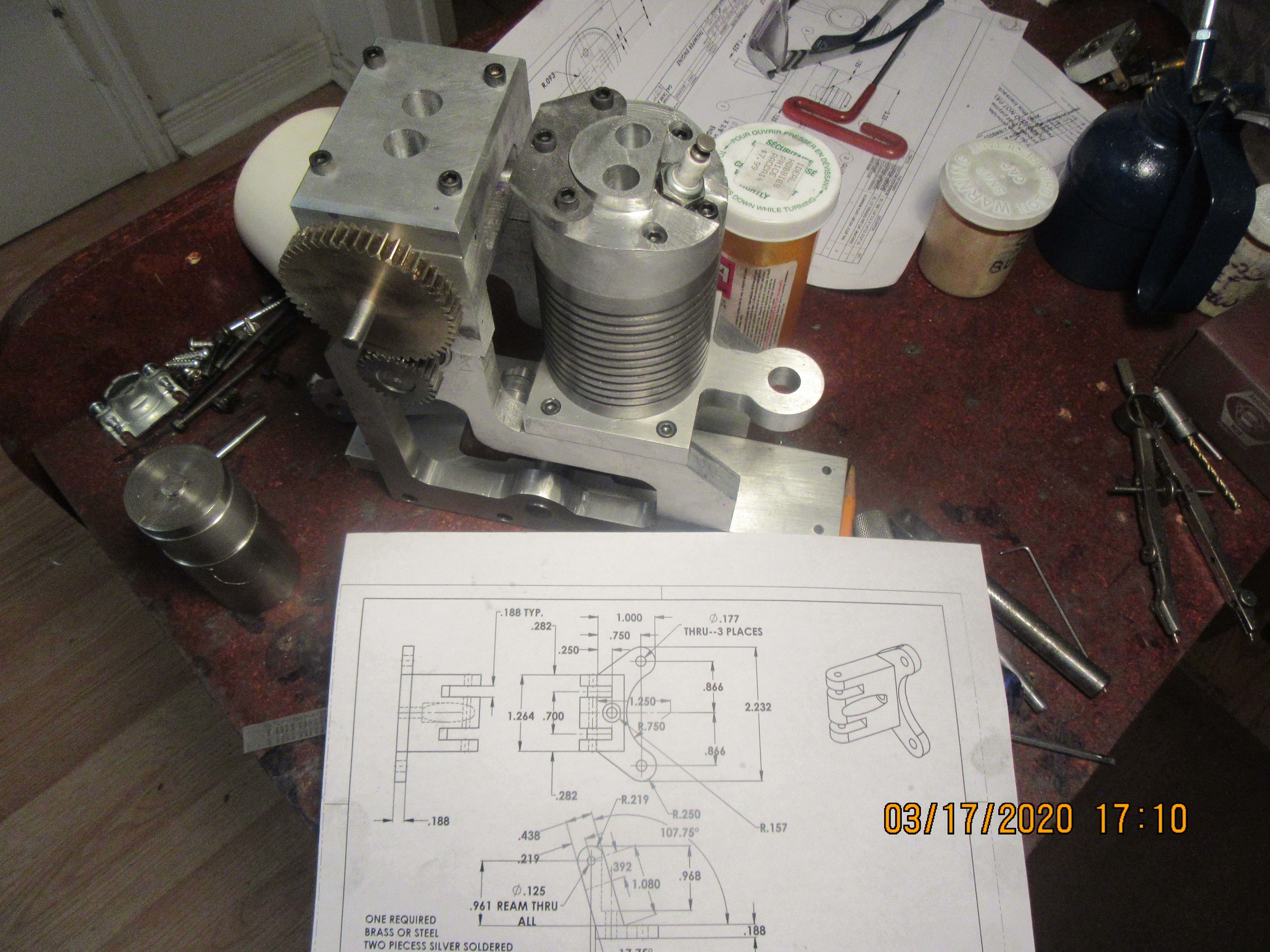

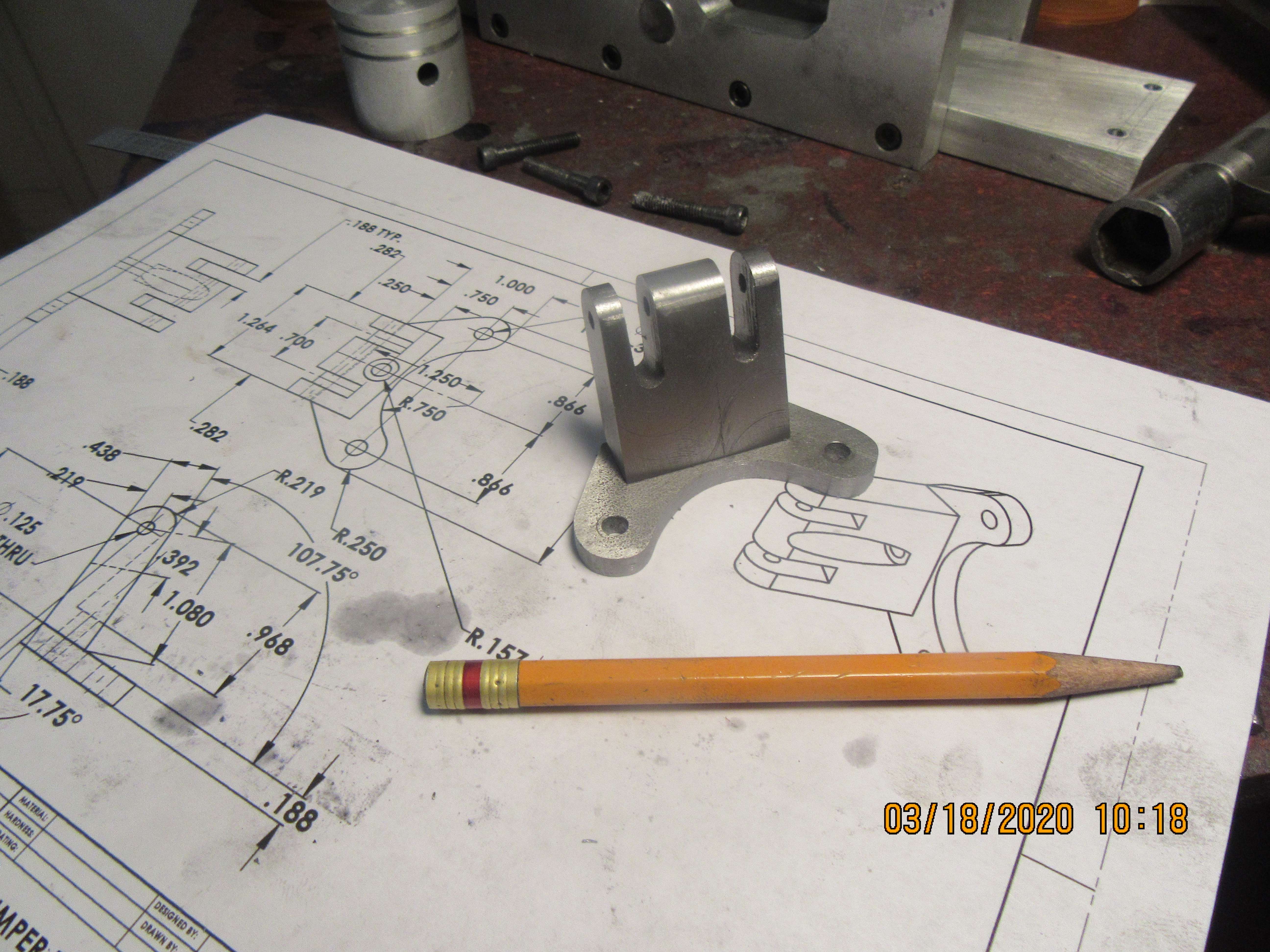

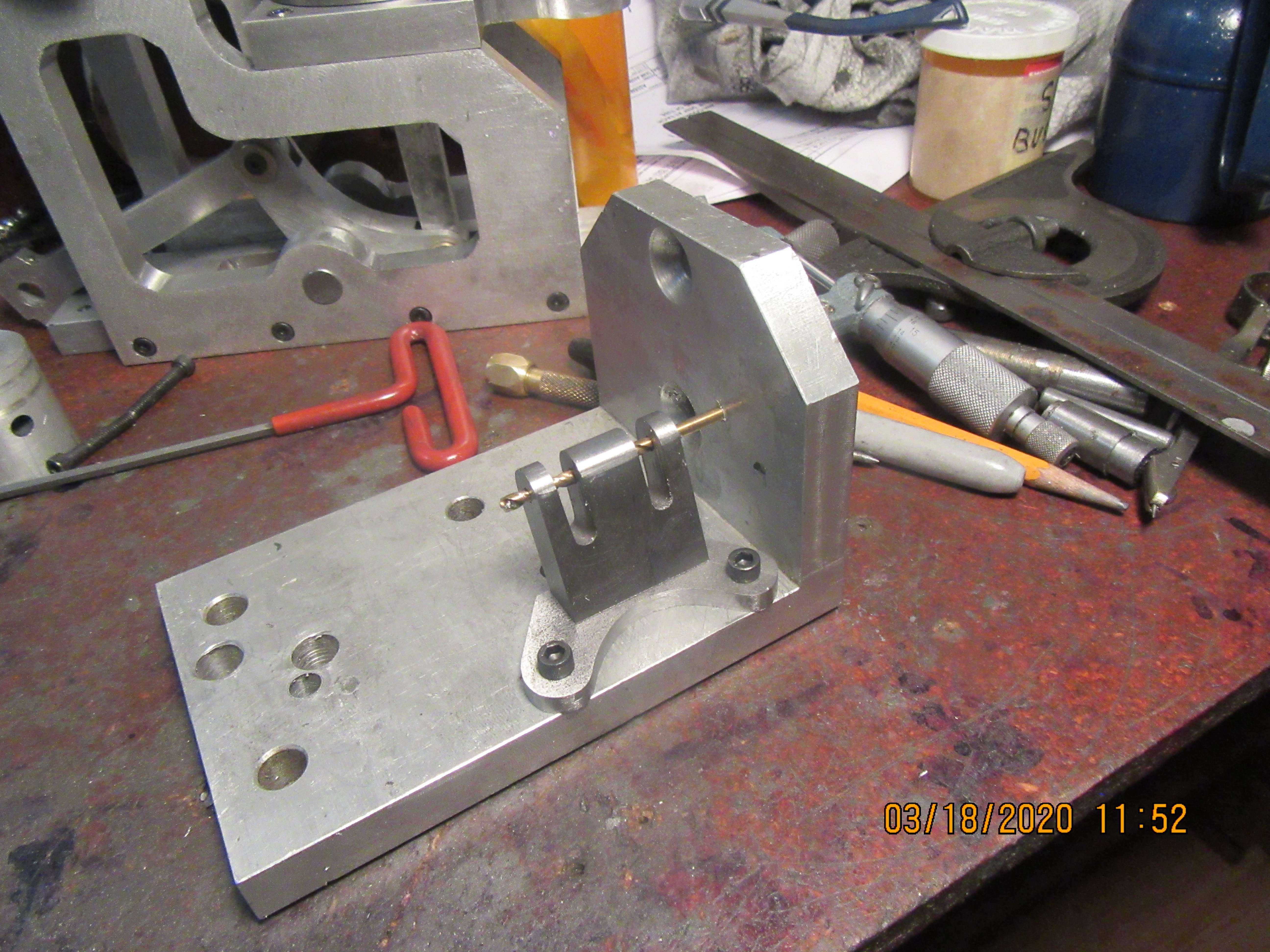

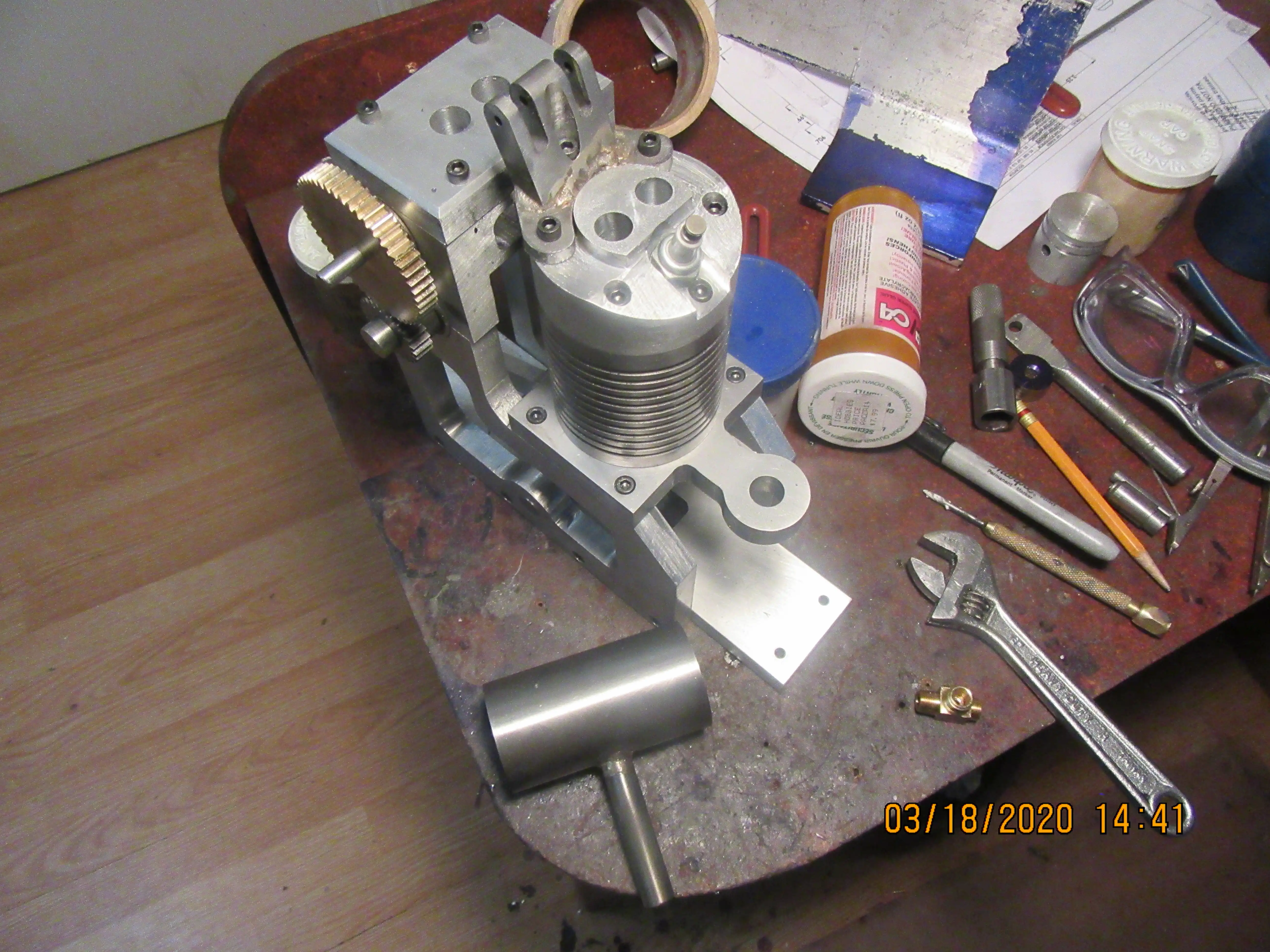

I am about 3/4 of the way through my building of the Henry Ford kitchen sink engine (my first IC engine from Mr. Ridenour’s plans) and already considering a design of my own.

My question to Brian, who has a significant amount of design experience is, does there exist a formula for determining top and bottom clearance in piston ring grooves for cast iron rings?

Just thinking ahead, and knowing of your successes, I thought if anyone knew, it’d be you!

Thanks in advance,

John W