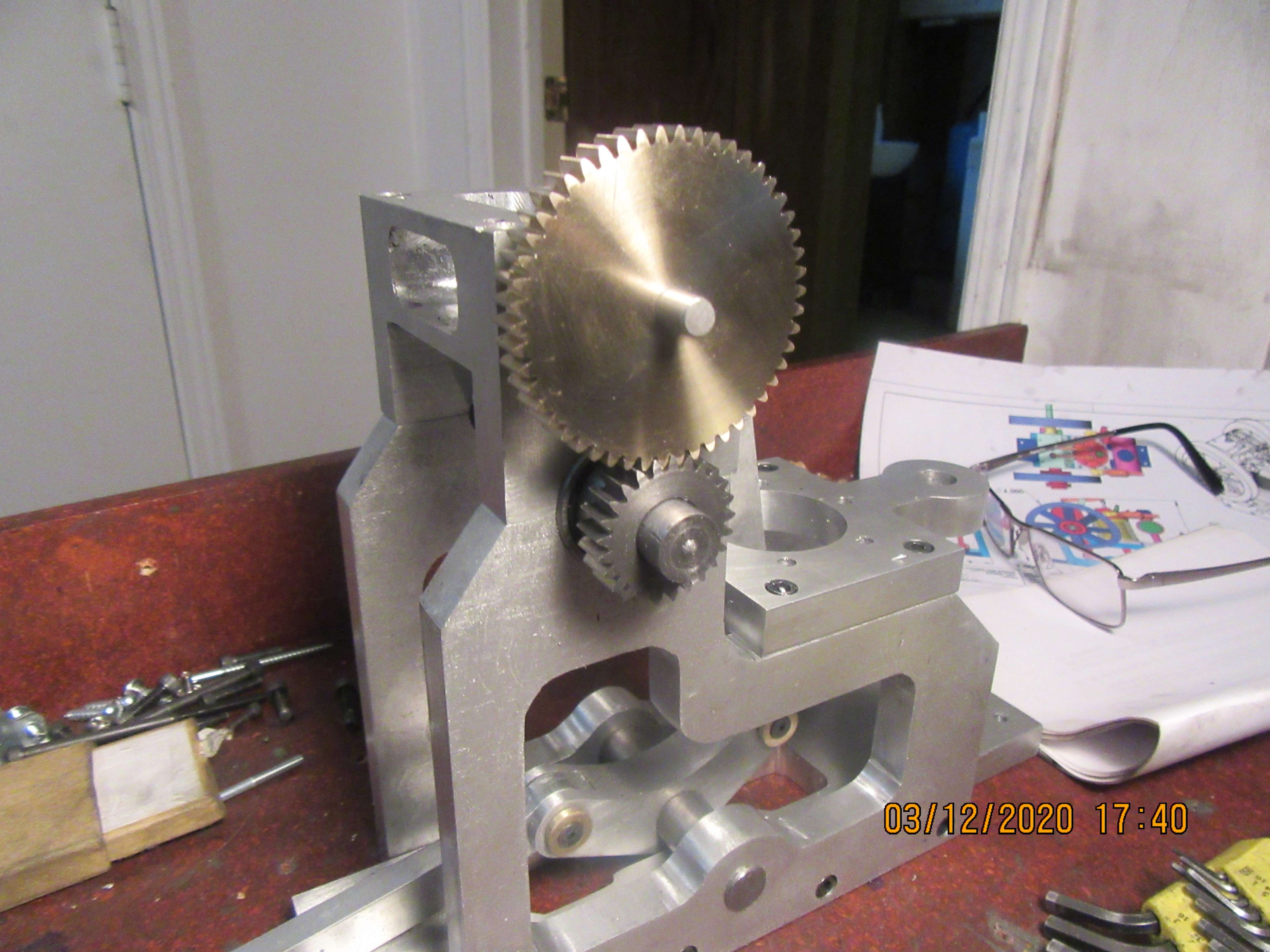

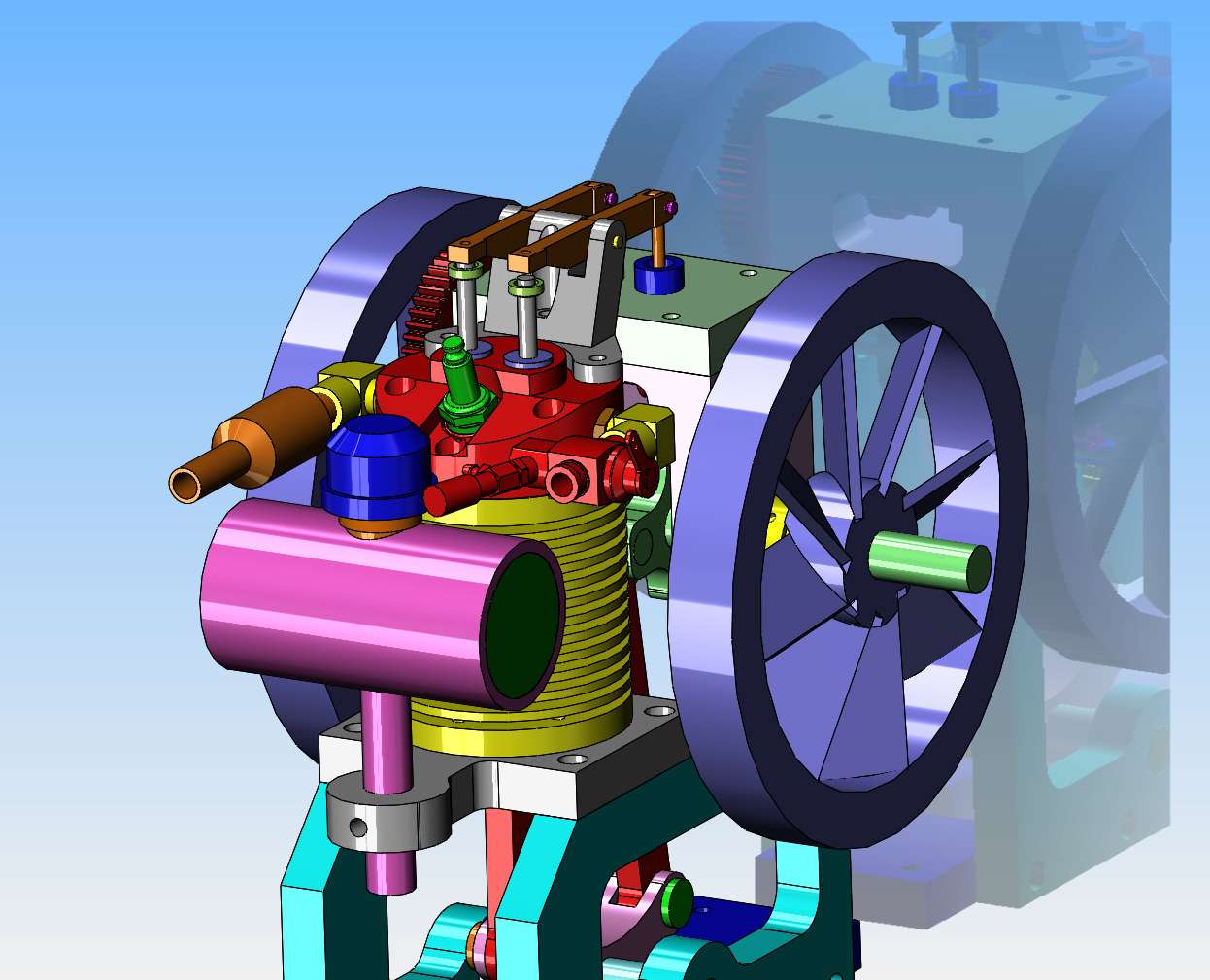

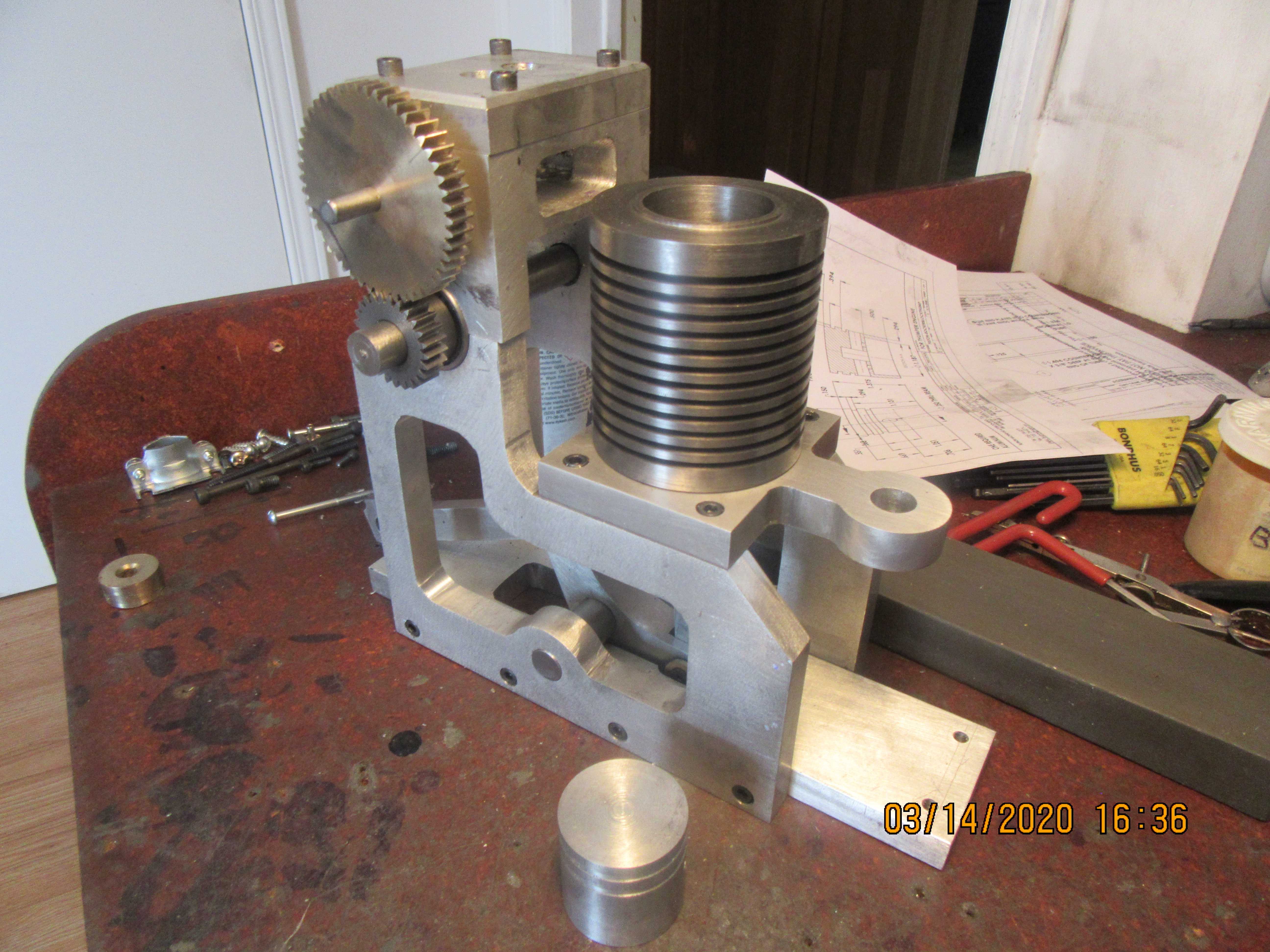

Brian, the engine is progressing nicely!

Sorry to hear that you are having trouble ringing Dave. I mean, getting rings from Dave. Or both. Wait, now I've confused myself ...

Sorry to hear that you are having trouble ringing Dave. I mean, getting rings from Dave. Or both. Wait, now I've confused myself ...