I actually did build a working muffler with baffles, etcetera for one of my engines. It did quiet the engine down quite considerably. It was just one of the ten thousand things I like to try to see "what if".

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Thumper--a 1 3/8" bore i.c. engine

- Thread starter Brian Rupnow

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Tomorrow I will designate as "Side plate day". The side-plates are pretty well identical, except that the counterbored holes make them right and left hand. It is much less work if I can do all of the profile work on both plates at the same time. I will bolt the plates together , putting the connecting holes somewhere in the center area that gets milled away as a "last step". One plate will be drilled and tapped, the other will have countersunk or counterbored holes in it so it will lay flat. even the counterbored holes can be put in---When I separate the plates the bottom plate can be flipped over and counterbored.

a41capt

Well-Known Member

Tomorrow I will designate as "Side plate day". The side-plates are pretty well identical, except that the counterbored holes make them right and left hand. It is much less work if I can do all of the profile work on both plates at the same time. I will bolt the plates together , putting the connecting holes somewhere in the center area that gets milled away as a "last step". One plate will be drilled and tapped, the other will have countersunk or counterbored holes in it so it will lay flat. even the counterbored holes can be put in---When I separate the plates the bottom plate can be flipped over and counterbored.

I’ve been doing similar stuff lately with components that are mirror images of each other, and have a lot of success using super glue as the bonding agent. When I’m done with the work, I either use a heat gun to separate the pieces if large, or an acetone soak for pieces that fit into one of my small tubs.

One way or another, they all get an acetone cleaning to remove the last traces of the glue. I guess I’ve been lucky so far in that they’ve all held together and didn’t separate during machining. Probably wouldn’t work well if there was higher heat.

John W

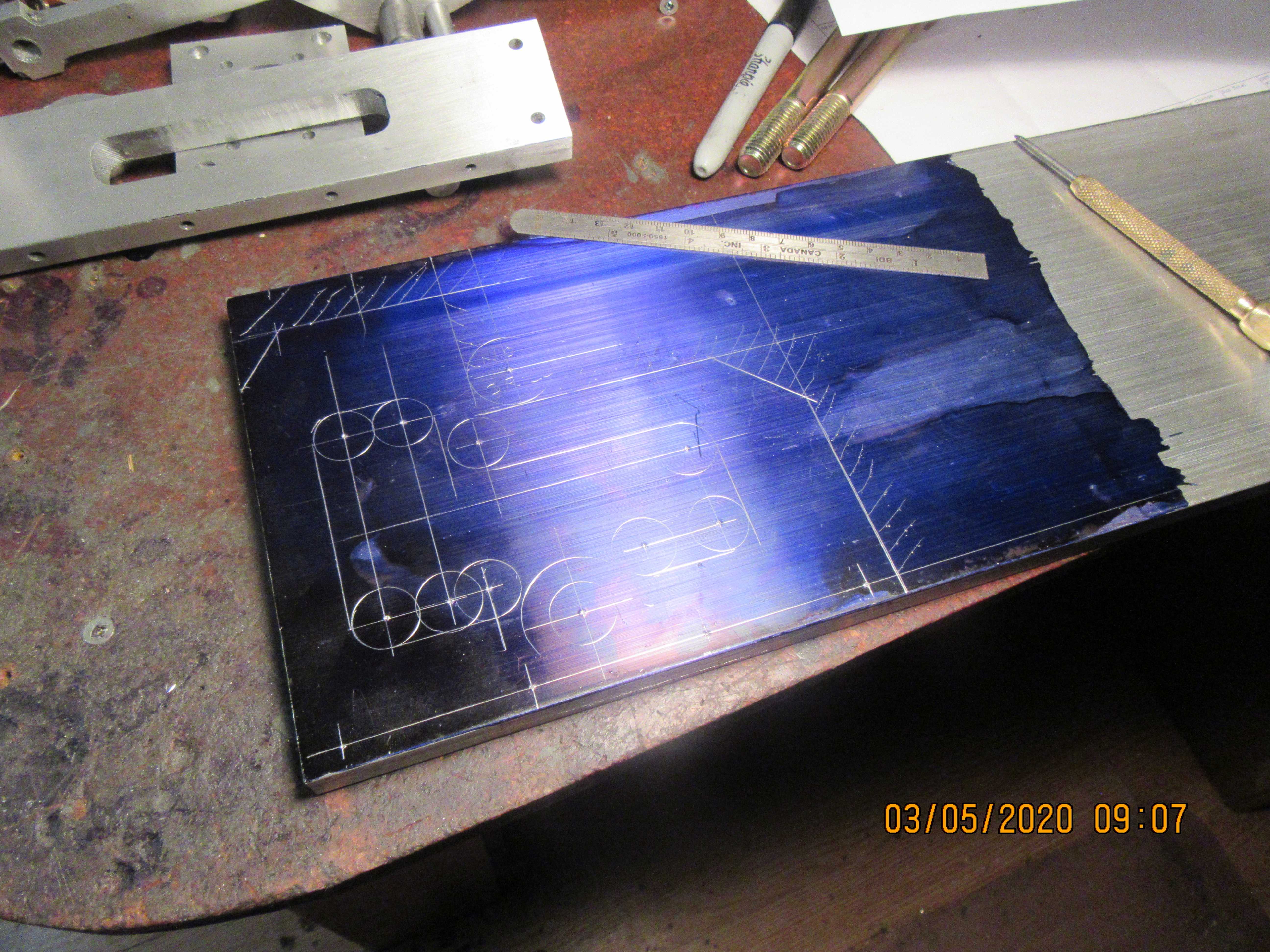

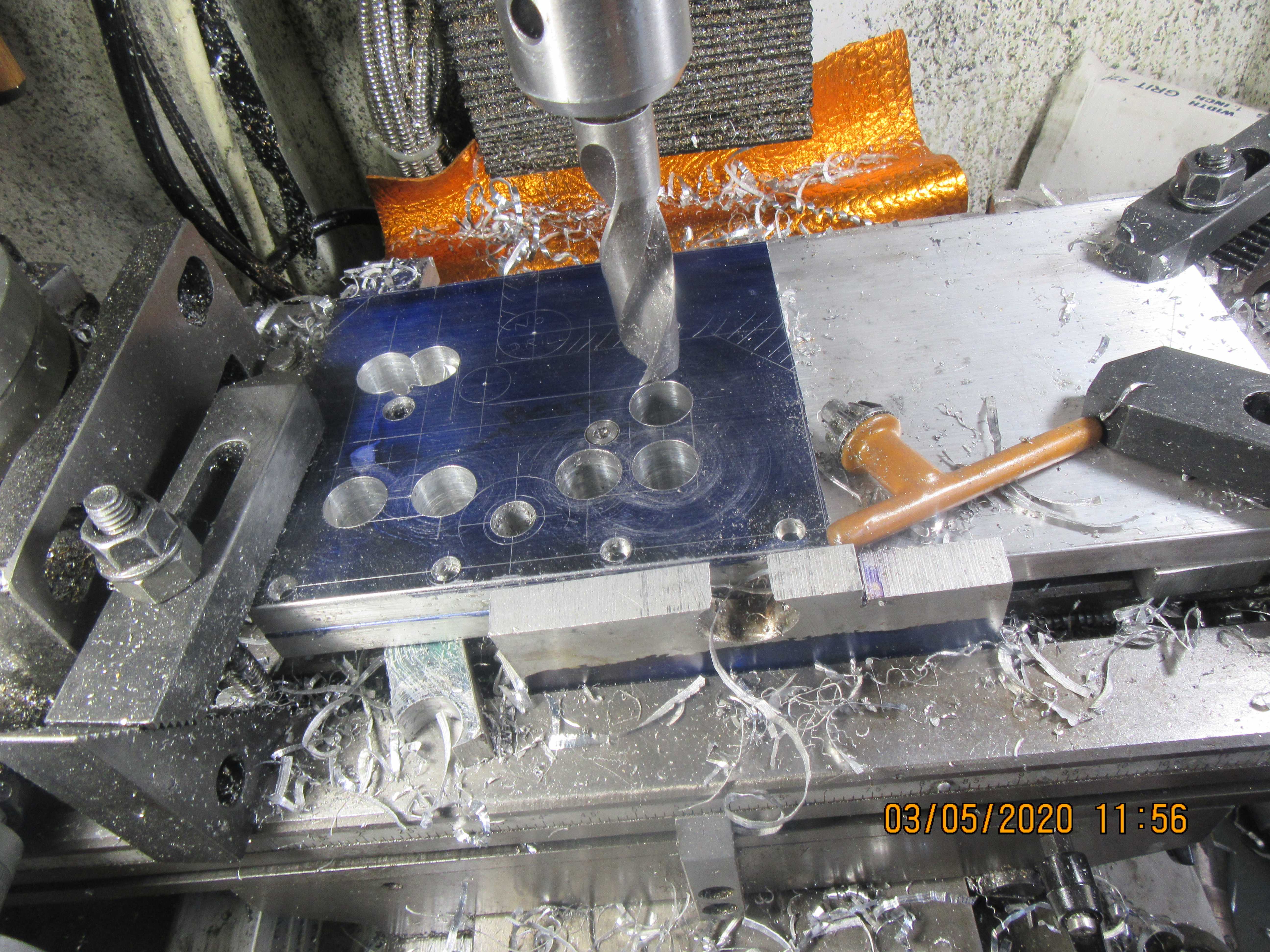

I came downstairs this morning with my cup of coffee and began laying out my side-plates. At this point I will join two pieces of material together, so all of the drilling and cutting applications ca be done at once on both plates. I trust my DRO's completely, but still lay everything out beforehand, just to be sure my layout makes sense and to give me assurance that I have the DRO in the places I really want to be.

Here we are with all of the major holes drilled. Eventually, all the center has to be cut out/machined away, and the outer profile machined. You can see the heads of the two 1/4" bolts which are holding the plates together.

- Joined

- Sep 2, 2011

- Messages

- 1,342

- Reaction score

- 360

maybe 1 hole for the outside radius not drilled?

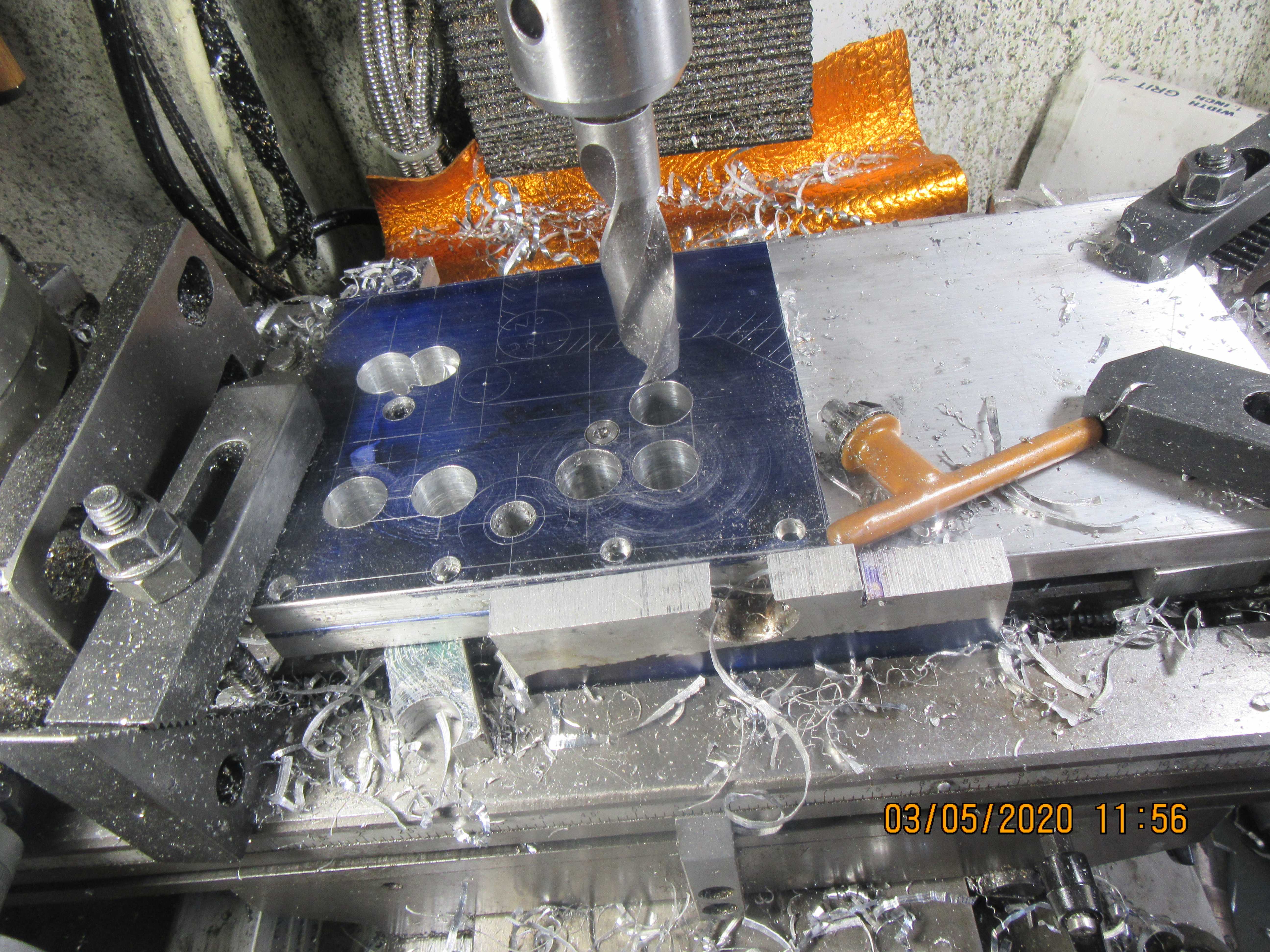

This pretty much covers the work that can be done with the two plates still bolted together. The exterior profile is completely machined, and a good portion of the inner profile. And it comes close to my own limits for the day. Tomorrow I will separate the plates and mill away what is left of the inner profile, and add some counterbores and some tapped holes.

Werowance--thanks for the reminder. I actually thought of that while eating my lunch. I'm glad that I hadn't torn down the set-up.---Brian

- Joined

- Sep 2, 2011

- Messages

- 1,342

- Reaction score

- 360

whats your plan of attack to cut this radius? freehand, rotary table or ??

After I get the rest of the inside profile cleaned out (within the next half hour) I will stand a short 1/2" diameter dowel vertically into the mill vice with about 3/4" protruding above the vice jaws. Then set a thick washer over the post, then set the 1/2" plate over the dowel. Bring the milling cutter down to a points where it is lined up with the underside of the plate, and start the mill on it's lowest speed. Then when I am sure it isn't going to "grab", I manually turn the plate on the 1/2" dowel, forcing the uncut plate into the cutter. This cuts a perfect radius, and is definitely not recommended as a safe practice.

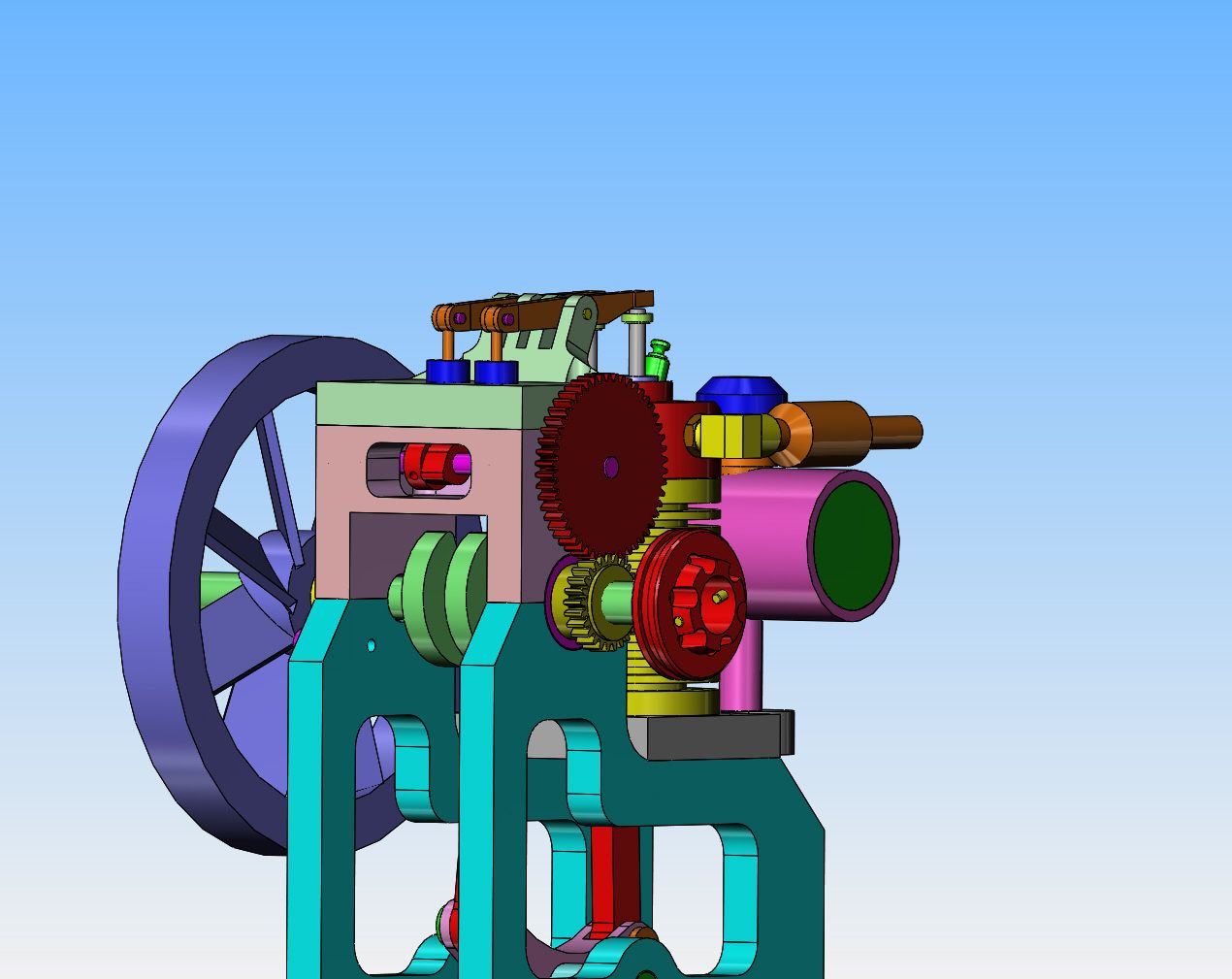

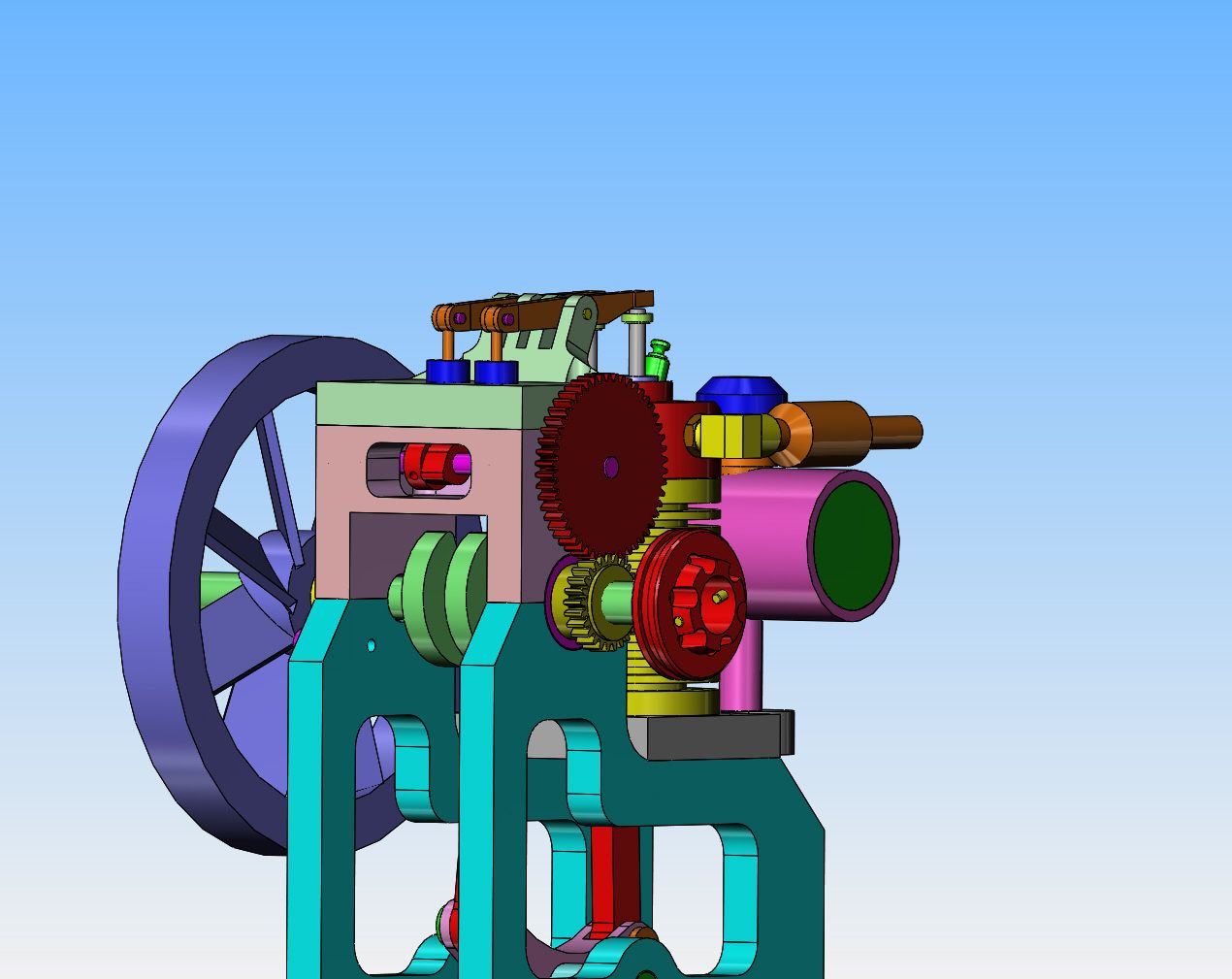

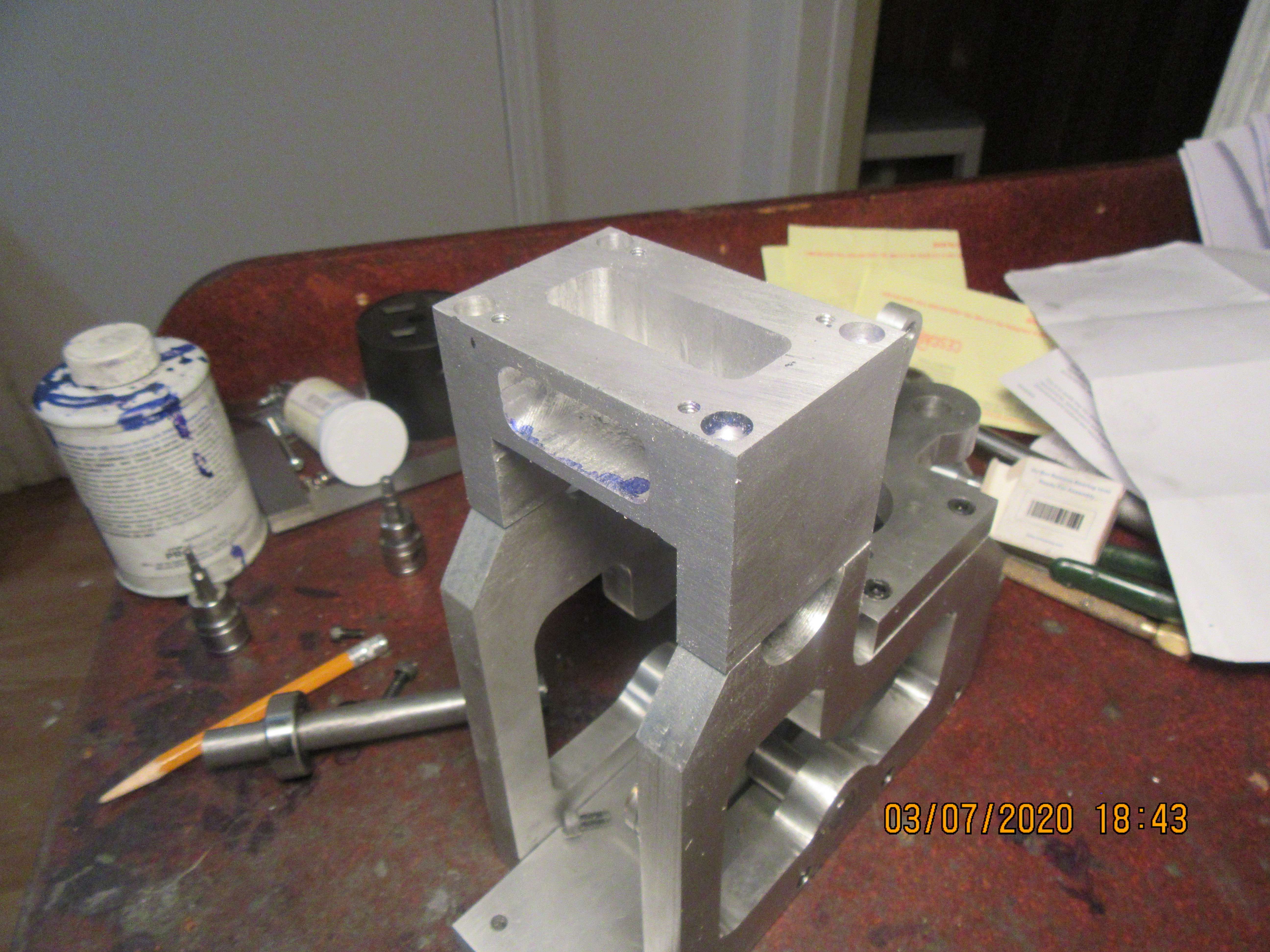

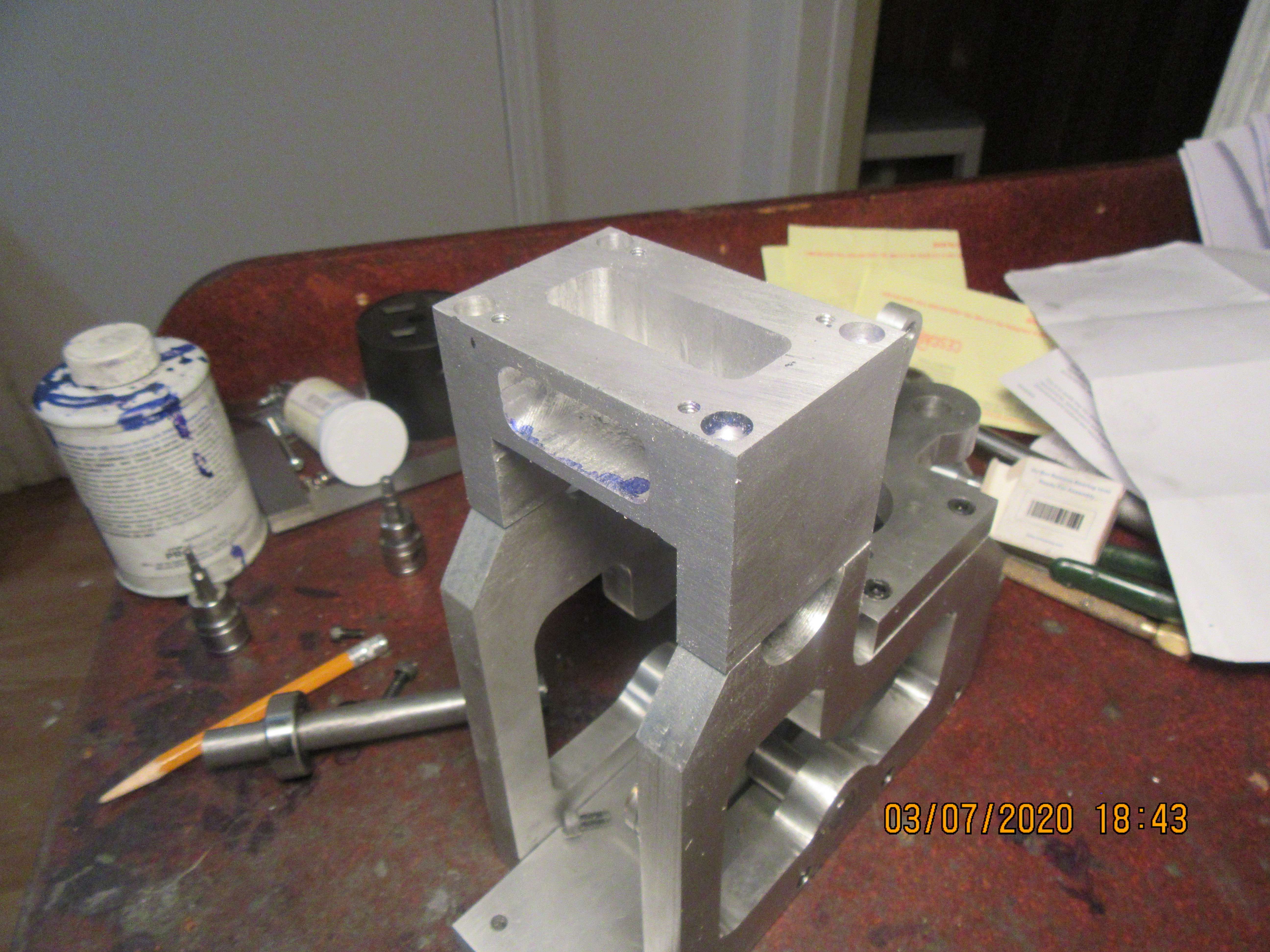

Today seen the completion of the side plates and first assembly of the overall frame. Everything goes together and everything clears. I will now order my piston rings. I don't want to make the piston until I have the rings and I don't want to make the cylinder until I have the piston. While I wait for the rings I will make the next part which sets on top, where the bearing caps would usually go.

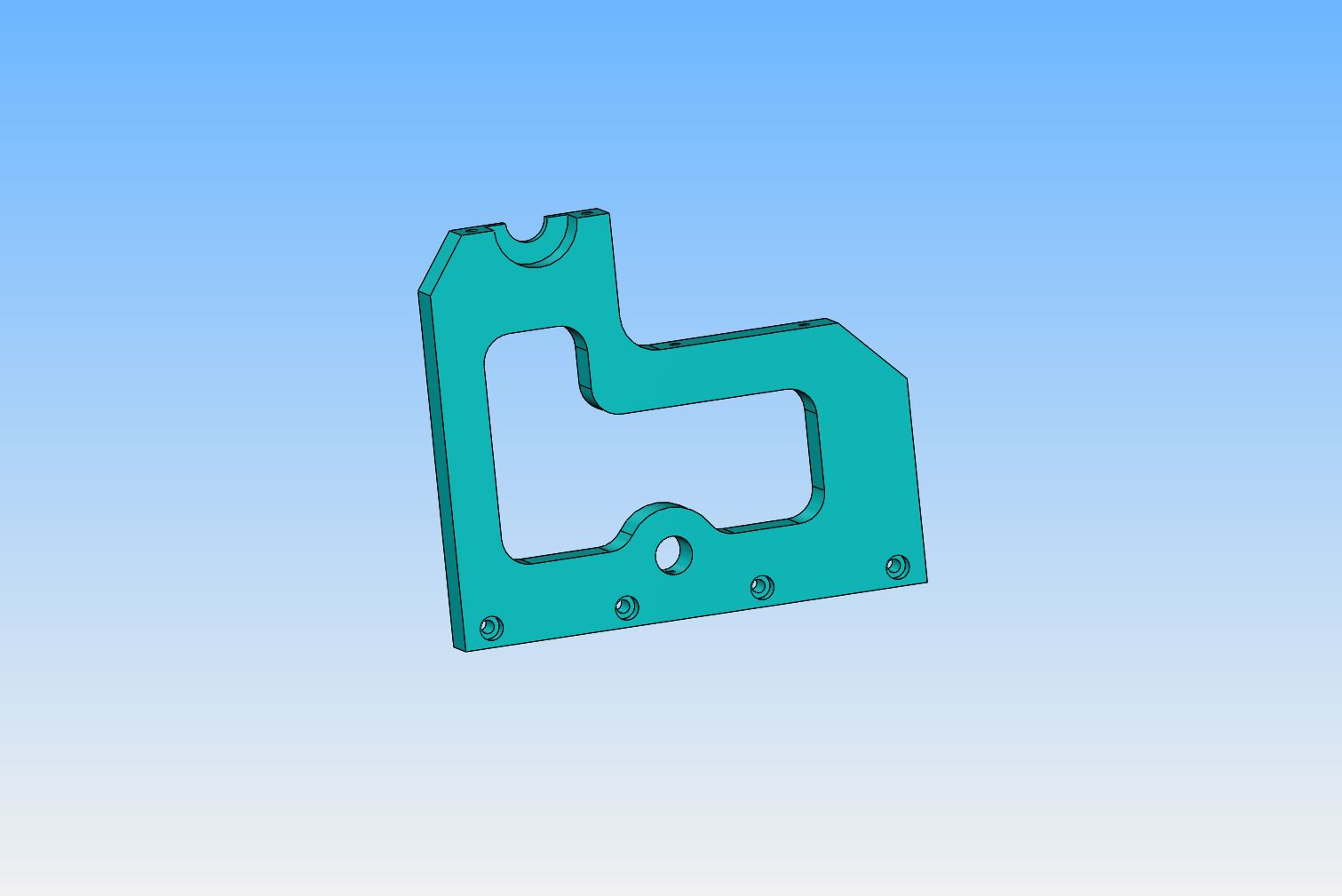

The next part that sets where the bearing caps would normally go is going to make my old heart go Pitter-Patter!! It is going to be a cam box, which has the camshaft bearings, camshaft and cams in it. The bolts which thread into the rest of the frame on each side of the main bearings pass thru this in clearance holes. The "window" cut into the side allows me access to the cams to set them at the proper rotational aspect.

Today I machined the cam box. It is finished except for the bores for the camshaft and bearings and the recess and clearance for the crankshaft bearings. I'm not sure if I can get #10 bolts that are long enough, but if I can't, then studs and nuts will work.

Something fishy is going on. I use ImageShack to post my photos on this forum. It automatically resizes my pictures to a size which is compatible with posting on the forum. Suddenly about half my posted pictures are HUGE on this forum only. Is anybody else seeing that with the pictures I post?--Brian

The first thing I noticed was the picture I got in the email was full-sized while the one on here was regular size. That was a few days ago. Within the day that turned into both the picture in the email and the copy here were both bigger.

I always cut my pictures down in size manually before I put them up, but I thought they'd end up a bit smaller than I'd post. I do that here with the "upload a file" button, not a place like ImageShack.

I always cut my pictures down in size manually before I put them up, but I thought they'd end up a bit smaller than I'd post. I do that here with the "upload a file" button, not a place like ImageShack.

- Joined

- Dec 31, 2010

- Messages

- 777

- Reaction score

- 195

They all look fine to me Brian. I went back right to the beginning. Some pictures have the "click here to enlarge the picture" click box at the top. (which makes them zoom about 10x - sort of useless). So maybe those were too big to fit. But they look ok in the post.

The photos I'm posting on my build are fine. But I just shoot them in 3Meg mode on my crappy camera and simply copy and paste them while I'm editing my post. I don't bother editing them before posting. They seem to fit and don't have the "click to enlarge" option. Dumb luck on the file sizing I guess.

https://www.homemodelenginemachinis...ngine-making-it-work.31960/page-2#post-335245

The photos I'm posting on my build are fine. But I just shoot them in 3Meg mode on my crappy camera and simply copy and paste them while I'm editing my post. I don't bother editing them before posting. They seem to fit and don't have the "click to enlarge" option. Dumb luck on the file sizing I guess.

https://www.homemodelenginemachinis...ngine-making-it-work.31960/page-2#post-335245

Last edited:

I was able to buy #10-24 shcs x 3" long today, and shortened them to 2 3/8". They worked fine and had enough thread that I didn't need to extend the thread with my #10-24 die. I've had some other stuff going on today, so didn't get any real machining time in on my project. Tomorrow I will set everything up on my milling machine and drill/bore the clearance for the crankshaft and the recessed bore for the crankshaft bearings, as well as the bores for the camshaft and bearings.

This morning was time to bore the cam box. I have learned thru experience, that this should be done with the cam box attached to the engine. First step was to attach the entire engine to an angle plate, set up square to the mill bed. The cam box was removed, and the bearing which sets in the sideplate recess was loctited to a piece of 1/2" shaft and held in the mill chuck. This allowed me to move the mill bed in both the x and y axis until the bearing was an exact fit into the recess cut for it. the DRO was set to "0" and the cam box was securely bolted in place. That allowed me to put in both the clearance hole for the crankshaft and the bore in the exact place it should be. Then it was time to move the mill table the required amount to put in the clearance hole in the cam box for the camshaft and cam bearing. I will now flip the engine over and repeat for the far side holes. I had to use a boring head to prepare the recess for the crankshaft. I got lucky and had an endmill of the exact size I needed for the camshaft bearing recess.

And here we are with all of the ball bearings and dummy shafts in place.

I can't reach Dave Reed at Ringspacers.com. I have emailed him and tried to telephone him, but nada. I want to buy a set of two rings for this engine I'm building but I can't reach Dave, who I've dealt with before. Are there any other reputable dealers that sell 1 3/8" dia x 3/32" thick piston rings for a 4 cycle i.c. engine?---Brian

Similar threads

- Replies

- 22

- Views

- 1K

- Replies

- 0

- Views

- 177