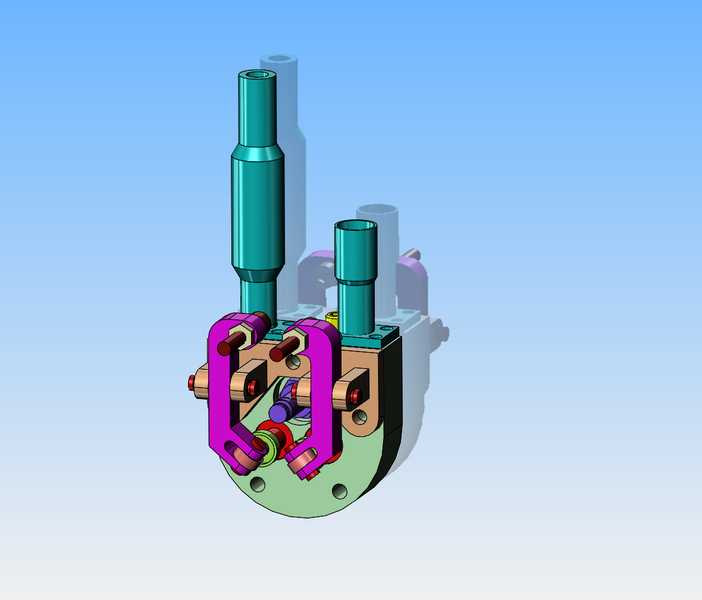

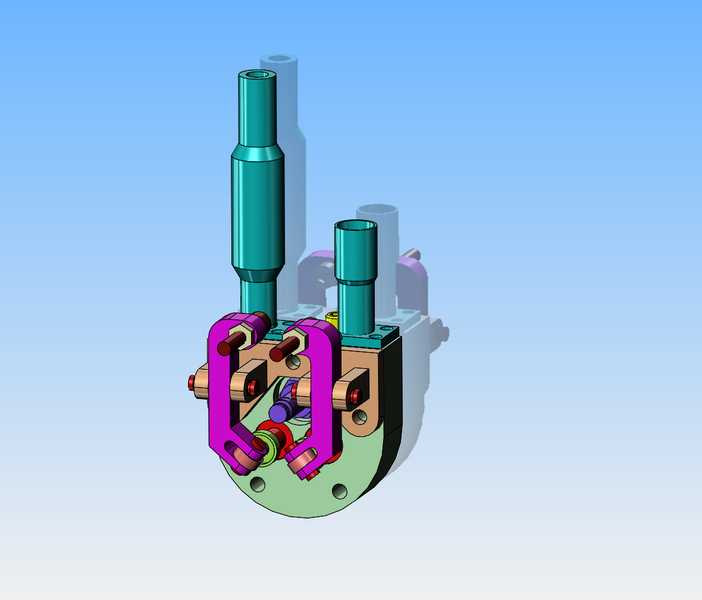

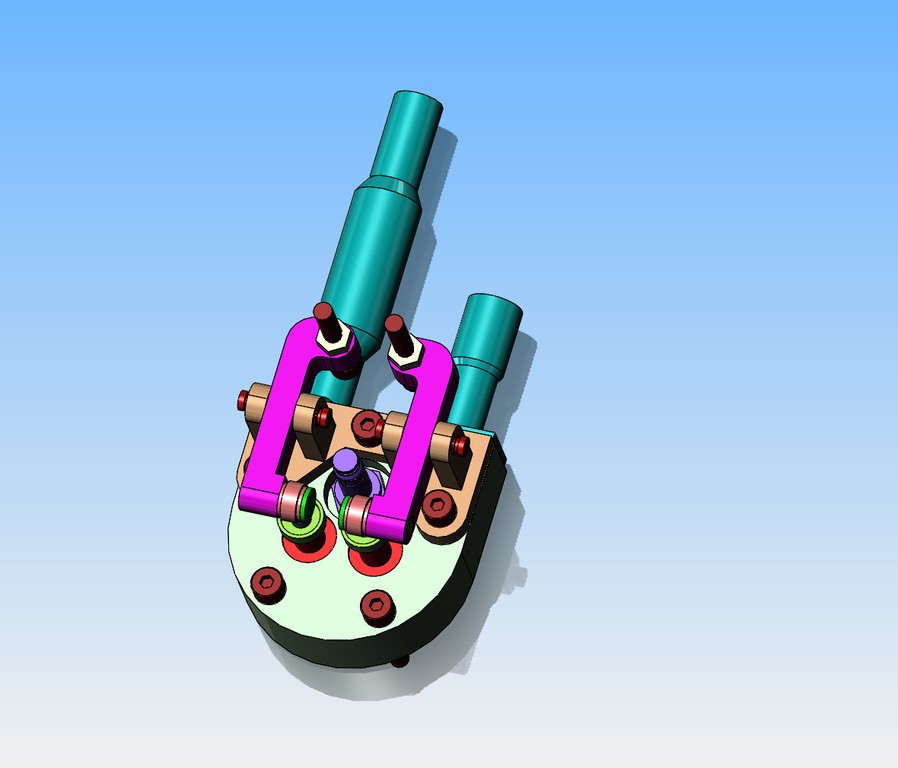

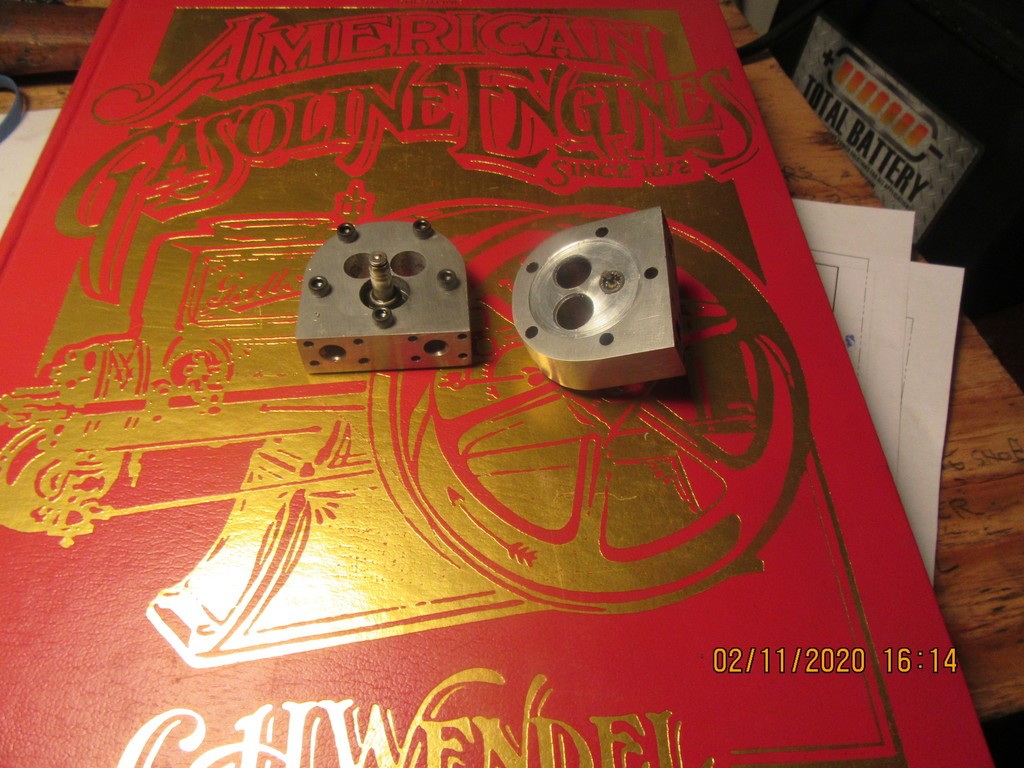

Okay--I spent the morning on a redesign of the cylinder heads. IF I decide to go ahead and do this, it would move the sparkplug up to a point above the centerline of the cylinder. It would mean new heads, and everything in them. That is a lot of work.--Then again, I don't have a lot of other stuff going on. The only thing that makes this a somewhat attractive notion, is that I have all the material here to do it without having to buy anything. I will think on this for a while---