Ive preferred grinding my own HSS lathe tools but lately Ive been trying out carbide and HSS inserts. One of the tools Ive always had trouble grinding accurately was a threading tool. It seems I can never get the angle exactly right, always just a tiny bit narrow or too wide.

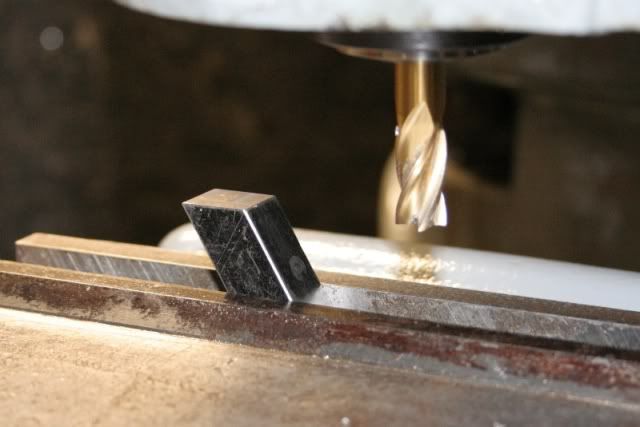

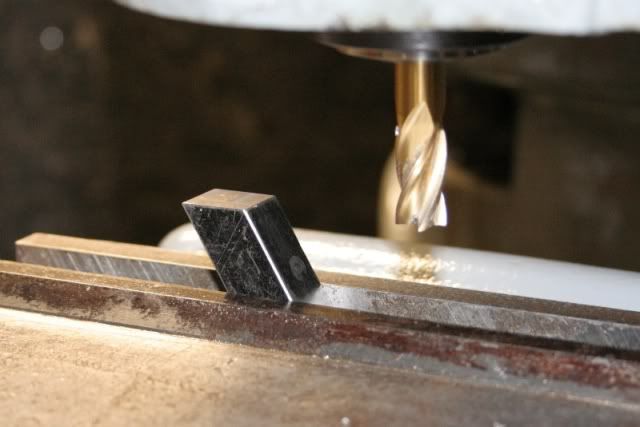

In my last tool order with LMS I picked up some HSS threading inserts. Now I needed to make a holder for them. I cut a piece of 1/2 inch square 1018 steel about 3 inches long. Since the inserts are triangular all the corners are 30 degrees. Getting out my trusty 30 degree angle plate I set up the square bar vertically and faced off the front horizontally.

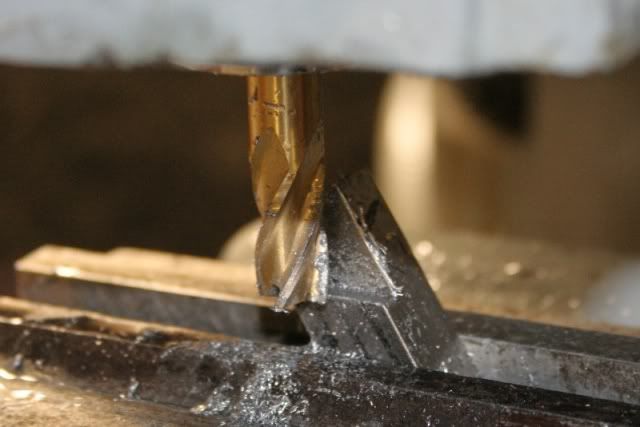

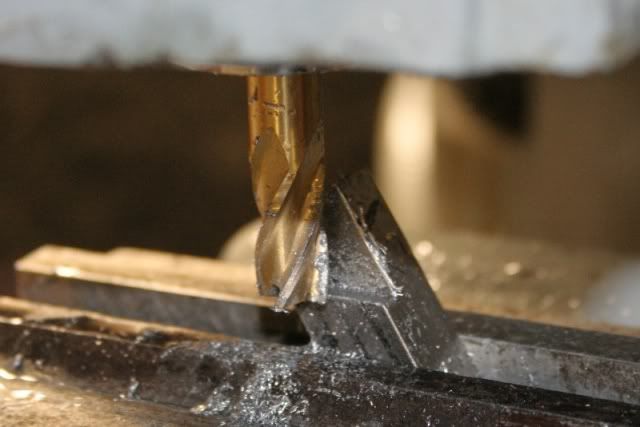

The bar was then flipped 180 degrees and also angled 30 degrees so the face I just finished is now vertical. A pocket for the insert was side milled .125 deep, the thickness of the insert.

One of the inserts was glued to the pocket with Locktite, then a transfer punch was used to mark the center of the screw hole. The bar was heated slightly to release the Locktite and back to the mill for drilling and tapping for a 6-32 screw.

An insert was mounted and a 35 degree angle was used to mark out the relief on the right side.

And done.

A couple test cuts done in 1/2 inch 4130 steel.

16 TPI on the left, 32 TPI on the right. Yeah, it was worth it!

In my last tool order with LMS I picked up some HSS threading inserts. Now I needed to make a holder for them. I cut a piece of 1/2 inch square 1018 steel about 3 inches long. Since the inserts are triangular all the corners are 30 degrees. Getting out my trusty 30 degree angle plate I set up the square bar vertically and faced off the front horizontally.

The bar was then flipped 180 degrees and also angled 30 degrees so the face I just finished is now vertical. A pocket for the insert was side milled .125 deep, the thickness of the insert.

One of the inserts was glued to the pocket with Locktite, then a transfer punch was used to mark the center of the screw hole. The bar was heated slightly to release the Locktite and back to the mill for drilling and tapping for a 6-32 screw.

An insert was mounted and a 35 degree angle was used to mark out the relief on the right side.

And done.

A couple test cuts done in 1/2 inch 4130 steel.

16 TPI on the left, 32 TPI on the right. Yeah, it was worth it!