You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

This is my projects so far.

- Thread starter hobby

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

- Joined

- Dec 5, 2009

- Messages

- 510

- Reaction score

- 47

Zeep,

Thankyou,

its progress, slow but sure, I still have a ways to go before I can

truly say it's done, but now comes the tweaking, and things..

Sam

Thanks,

I think the only bling I'll be able to give it is first finish it, :big:

But I was thinking about making a wooden form on the bottom, to make it look like an oil pan, to give it some shape, and fabricate a proportional size propeller, to make it look like it has some purpose... ;D

Then add extra's here and there, if I don't get overly anxious to get it done, so I can begin another project...

------------------------------

Have a great day...

Thankyou,

its progress, slow but sure, I still have a ways to go before I can

truly say it's done, but now comes the tweaking, and things..

Sam

Thanks,

I think the only bling I'll be able to give it is first finish it, :big:

But I was thinking about making a wooden form on the bottom, to make it look like an oil pan, to give it some shape, and fabricate a proportional size propeller, to make it look like it has some purpose... ;D

Then add extra's here and there, if I don't get overly anxious to get it done, so I can begin another project...

------------------------------

Have a great day...

- Joined

- Dec 5, 2009

- Messages

- 510

- Reaction score

- 47

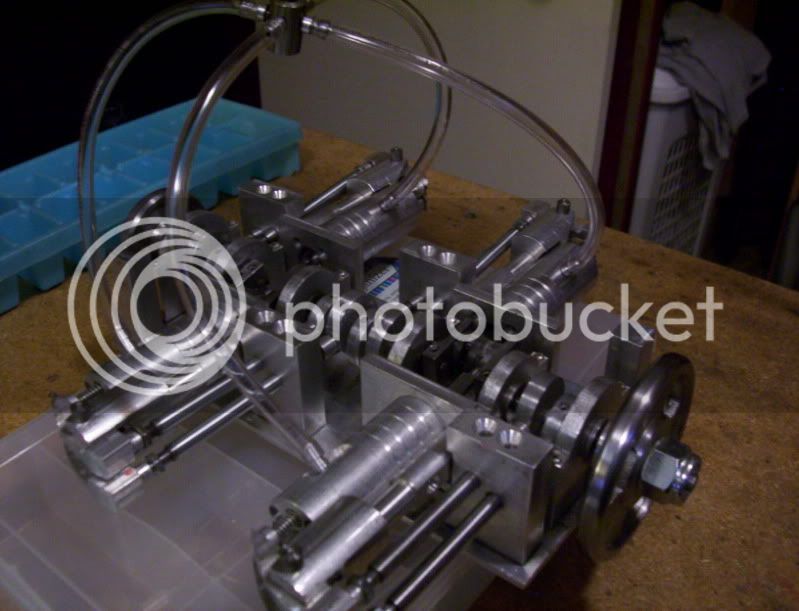

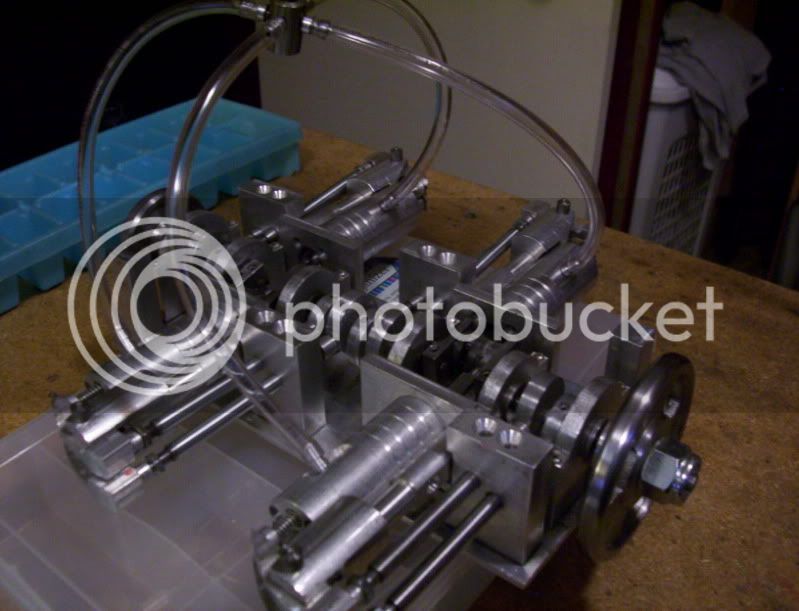

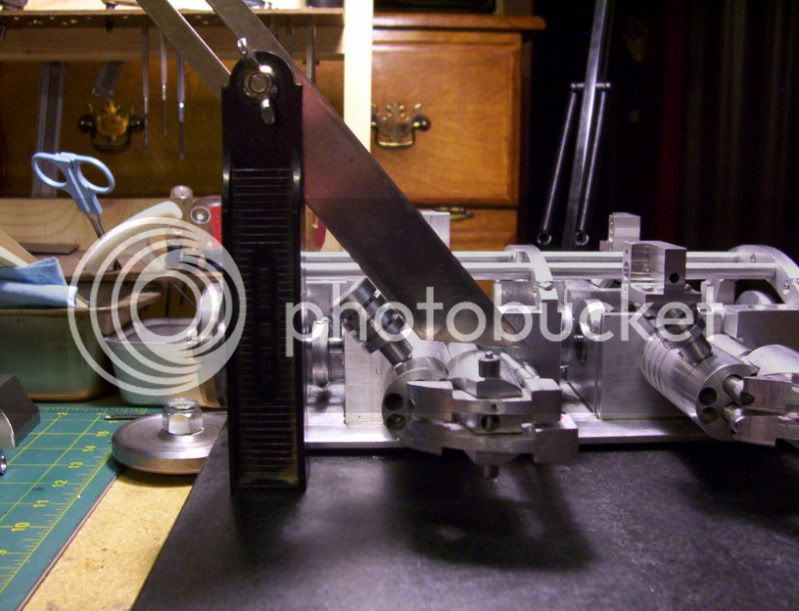

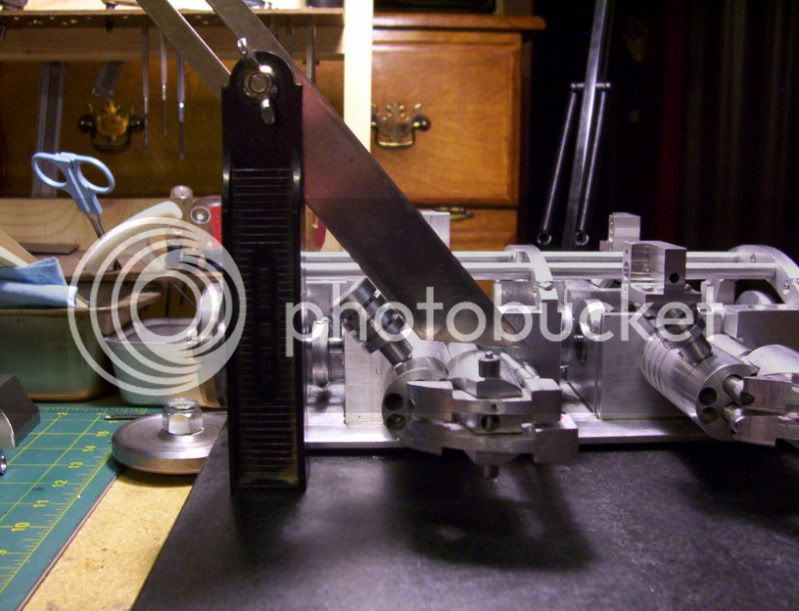

This is next to the last update,

This shows the engine with Temporary tubing going to the intakes on all cylinders,

This setup was used to test run the engine on all 4 cylinders.

I don't want to show a video of it right here, because I want to wait until I get all the bells and whistles done on it, then I'll post it in a seperate thread, with a video of it running.

Here it is in raw form, working mechanical stage, BEFORE the finish work. Temporary tubing, at this point..

Next time I post about this build, it will have all fabricated and machined intake manifold tubings, and probably a propeller.

Thanks for looking...

This shows the engine with Temporary tubing going to the intakes on all cylinders,

This setup was used to test run the engine on all 4 cylinders.

I don't want to show a video of it right here, because I want to wait until I get all the bells and whistles done on it, then I'll post it in a seperate thread, with a video of it running.

Here it is in raw form, working mechanical stage, BEFORE the finish work. Temporary tubing, at this point..

Next time I post about this build, it will have all fabricated and machined intake manifold tubings, and probably a propeller.

Thanks for looking...

- Joined

- Dec 5, 2009

- Messages

- 510

- Reaction score

- 47

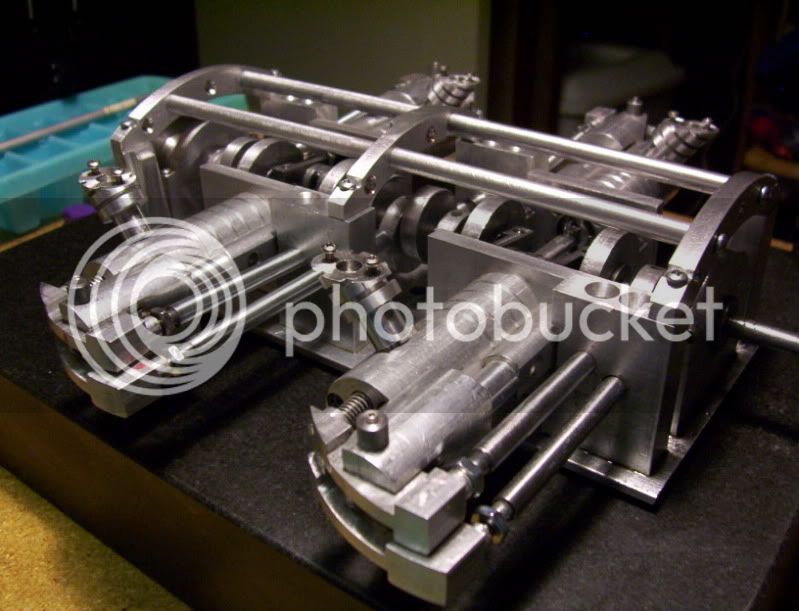

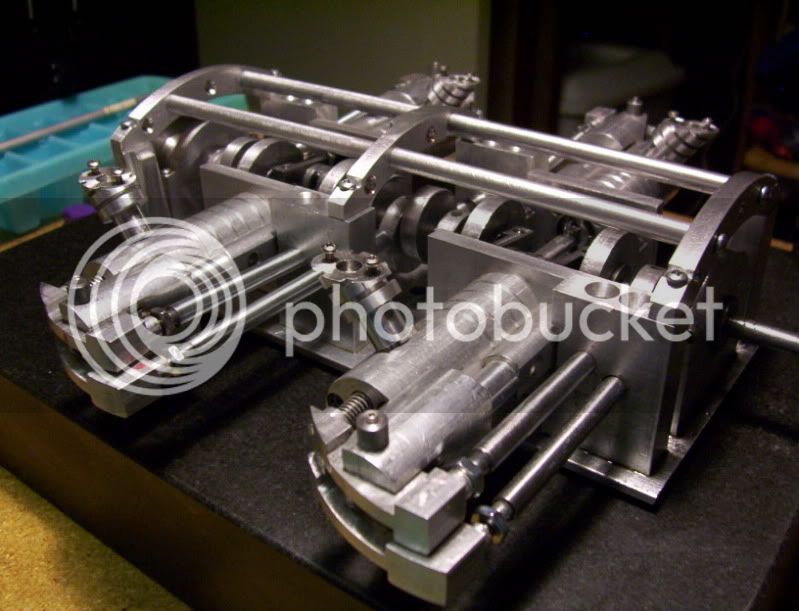

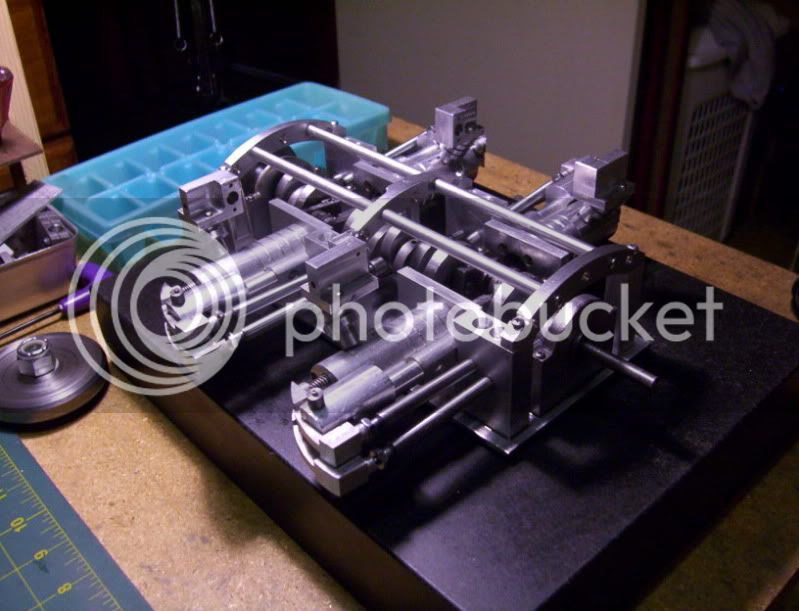

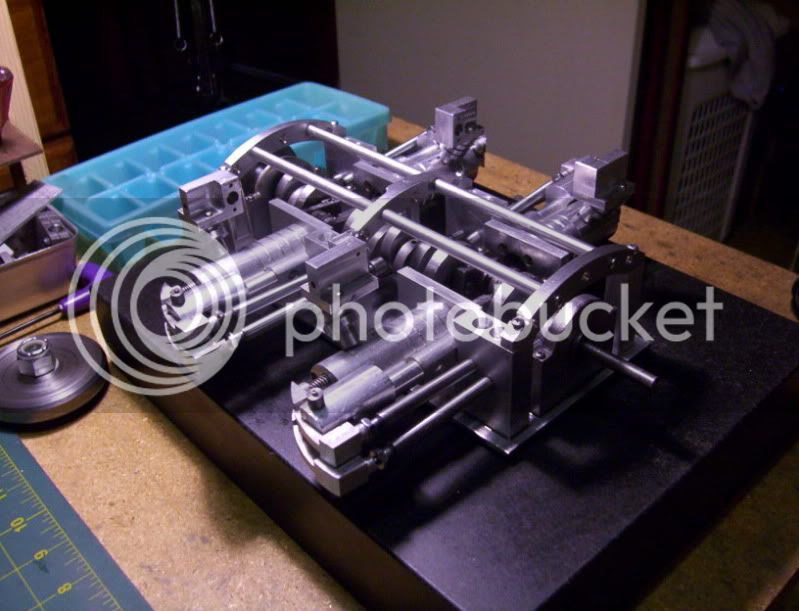

Hi everyone,

I was going to wait until this was all done, before I post on this,

but I decided to post some more updates on my engine,

so you know that there is progress being done on it.

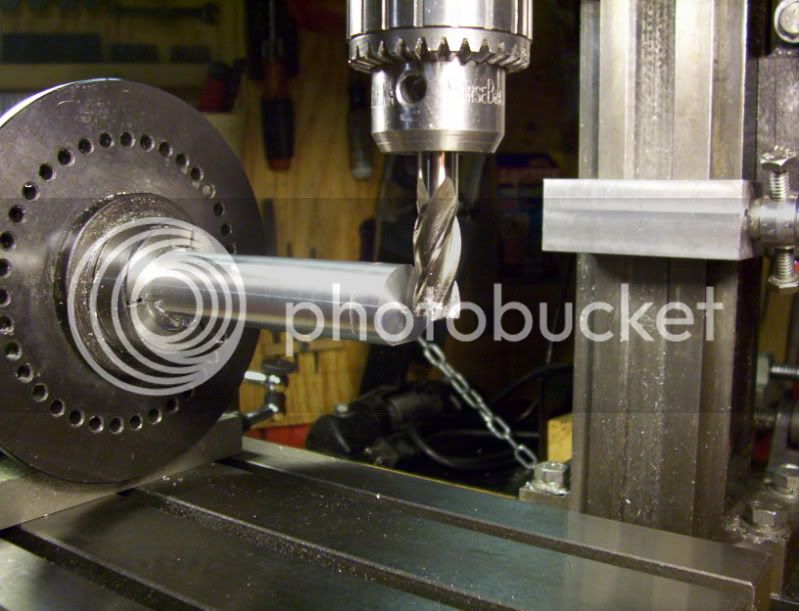

The first picture is the jig I made for my rotary table to cut out the arches for the framework,

at the top of the engine.

And here is that framework.

Then today I began fabricating the, air intake manifolds for each cylinder,

that's the small angle cut cylinders on top of each piston cylinder.

I made each manifold from 5/8" round stock, and put a 1/8" x .120" dia. nub on one end,

and then using a 6-32 die, threaded it.

Also above that for 3/8" I turned the stock to 0.375" dia. and then using a cutoff tool, made cuts in the 5/8" dia. top part, to look like some kind of cooling fins, just for asthetics, then also a 5/64" thru hole is drilled thru, for air inlet.

After that I made a fixture, to hold each one at the proper angle, to use a slitting saw, to cut them to proper angle and length. Then drilled and reamed a 1/4" dia. hole for fitting the air intake tube, and drilled and tapped 2 holes per each one, to attach the flange of the intake tubing, to follow.

So this picture is where its at to date...

Next is to draw up and fabricate, the air intake system to tie it all together.

Thankyou...

I was going to wait until this was all done, before I post on this,

but I decided to post some more updates on my engine,

so you know that there is progress being done on it.

The first picture is the jig I made for my rotary table to cut out the arches for the framework,

at the top of the engine.

And here is that framework.

Then today I began fabricating the, air intake manifolds for each cylinder,

that's the small angle cut cylinders on top of each piston cylinder.

I made each manifold from 5/8" round stock, and put a 1/8" x .120" dia. nub on one end,

and then using a 6-32 die, threaded it.

Also above that for 3/8" I turned the stock to 0.375" dia. and then using a cutoff tool, made cuts in the 5/8" dia. top part, to look like some kind of cooling fins, just for asthetics, then also a 5/64" thru hole is drilled thru, for air inlet.

After that I made a fixture, to hold each one at the proper angle, to use a slitting saw, to cut them to proper angle and length. Then drilled and reamed a 1/4" dia. hole for fitting the air intake tube, and drilled and tapped 2 holes per each one, to attach the flange of the intake tubing, to follow.

So this picture is where its at to date...

Next is to draw up and fabricate, the air intake system to tie it all together.

Thankyou...

- Joined

- Dec 5, 2009

- Messages

- 510

- Reaction score

- 47

Jtrain,

Thankyou for the compliment.

Also Ironhorse,

Thankyou for your kind compliment.

sorry for being so late with an acknowledgement to your post, I was just starting out new with this forum, and forgot to even check up on any updates in this thread, until I started posting updates again, and as I was going over this entire thread tonight, I seen your compliments, and thought I need to acknowledge back.

Also anyone I may have missed, I will see if there is anymore I missed achknowledging back.

Thankyou Gmac.

Thankyou BillMC.

For the nice comments.

Have a great day..

Thankyou for the compliment.

Also Ironhorse,

Thankyou for your kind compliment.

sorry for being so late with an acknowledgement to your post, I was just starting out new with this forum, and forgot to even check up on any updates in this thread, until I started posting updates again, and as I was going over this entire thread tonight, I seen your compliments, and thought I need to acknowledge back.

Also anyone I may have missed, I will see if there is anymore I missed achknowledging back.

Thankyou Gmac.

Thankyou BillMC.

For the nice comments.

Have a great day..

zeeprogrammer

Well-Known Member

- Joined

- Mar 14, 2009

- Messages

- 3,362

- Reaction score

- 13

kustomkb said:I love the mechanicalness of it all.

What Kevin said. I am really looking forward to a video of this.

- Joined

- Dec 5, 2009

- Messages

- 510

- Reaction score

- 47

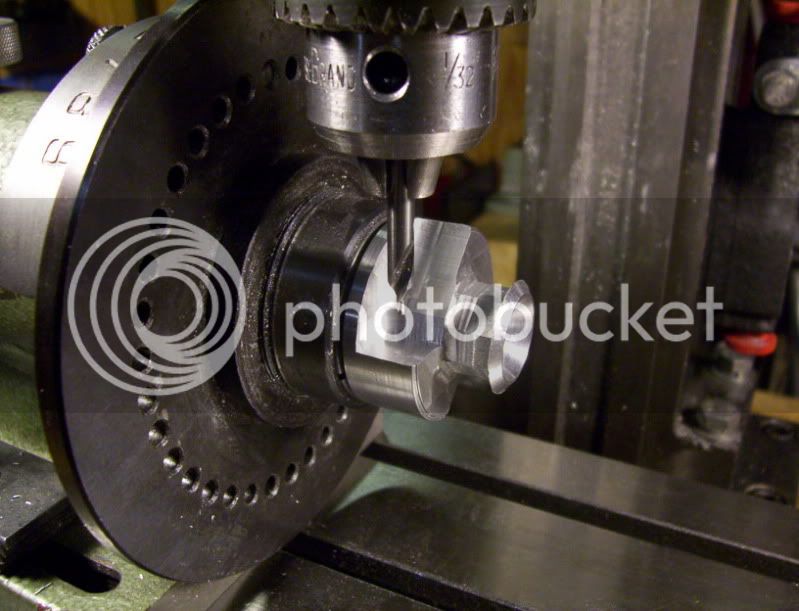

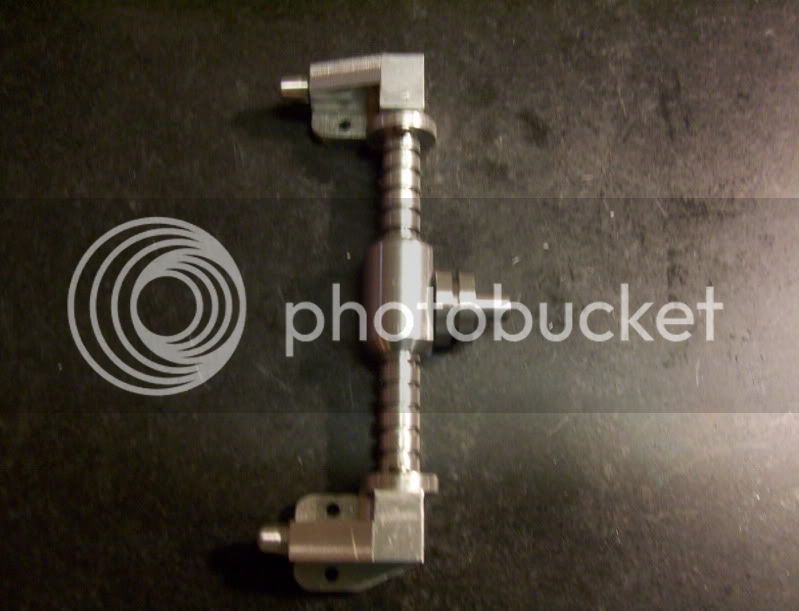

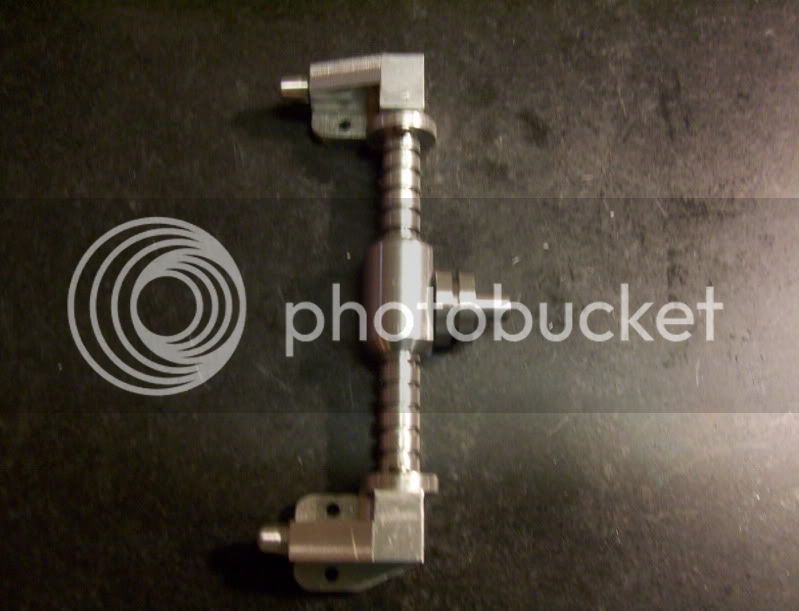

Hi,

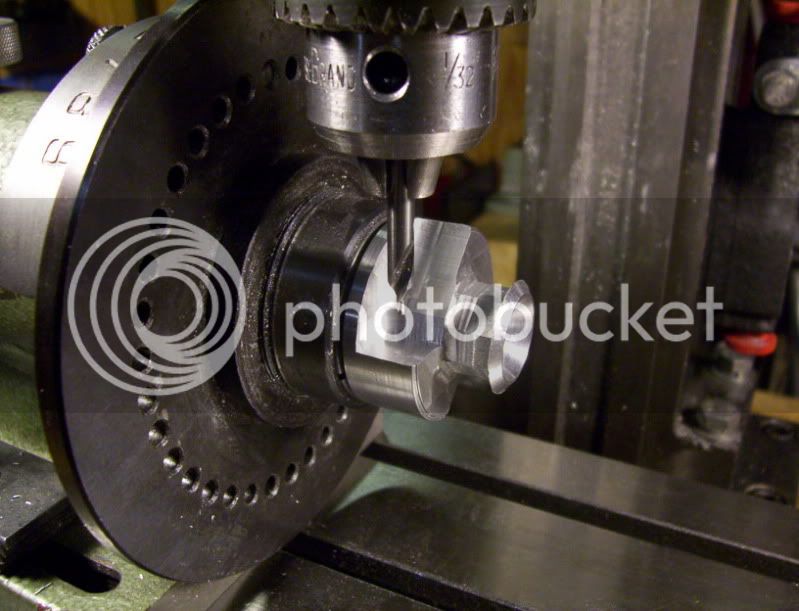

Some more updates, not very exciting but just to let you know where I'm at in this build.

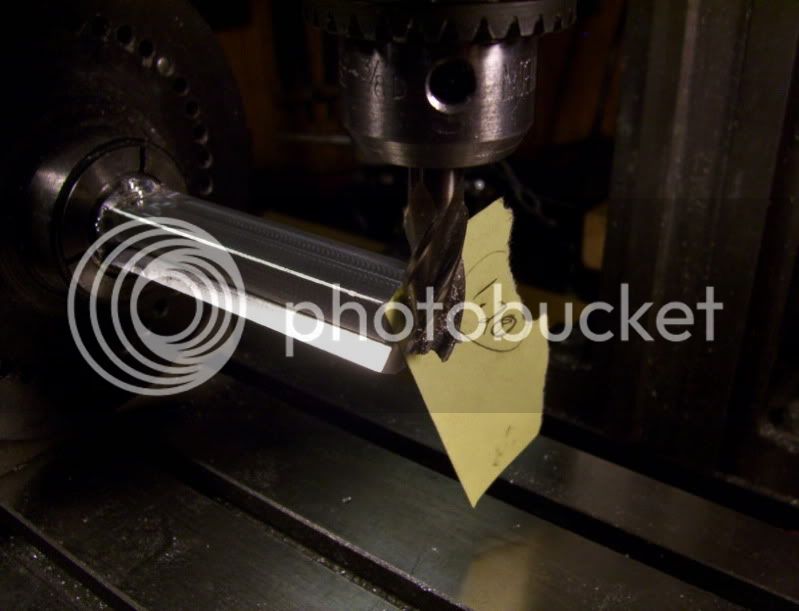

The intake ports I made before, needed to be made over, because I made a quick an inacurate fixture using round bar, with flats machined on it that could not be clamped to securely in my vice, as well as a inacurate gauge made out of a credit card to transfer the angle, which meant uneven cuts.Bad setup all together.

So I took the time to make a good fixture out of square flat stock, that could be positioned and clamped securely in my vice.

As well as using my sliding T Bevel to acurately locate and transfer the angle to my workpieces.. Each intake part was guaged with this bevel square,

and transfered to my milling fixture.

Then was cut to desired length and angle,

enlarged the intake port with a 1/4" drill, to depth of 1/8"

then transversed the table 1/4" to drill and tap for a 2-56 screw hole.

Then screwed it in place back on the engine.

Here they are with the air intake tube brackets fastened to them.

These square brackets will be milled with some details so there not just square blocks.

Thanks...

Some more updates, not very exciting but just to let you know where I'm at in this build.

The intake ports I made before, needed to be made over, because I made a quick an inacurate fixture using round bar, with flats machined on it that could not be clamped to securely in my vice, as well as a inacurate gauge made out of a credit card to transfer the angle, which meant uneven cuts.Bad setup all together.

So I took the time to make a good fixture out of square flat stock, that could be positioned and clamped securely in my vice.

As well as using my sliding T Bevel to acurately locate and transfer the angle to my workpieces.. Each intake part was guaged with this bevel square,

and transfered to my milling fixture.

Then was cut to desired length and angle,

enlarged the intake port with a 1/4" drill, to depth of 1/8"

then transversed the table 1/4" to drill and tap for a 2-56 screw hole.

Then screwed it in place back on the engine.

Here they are with the air intake tube brackets fastened to them.

These square brackets will be milled with some details so there not just square blocks.

Thanks...

- Joined

- Dec 5, 2009

- Messages

- 510

- Reaction score

- 47

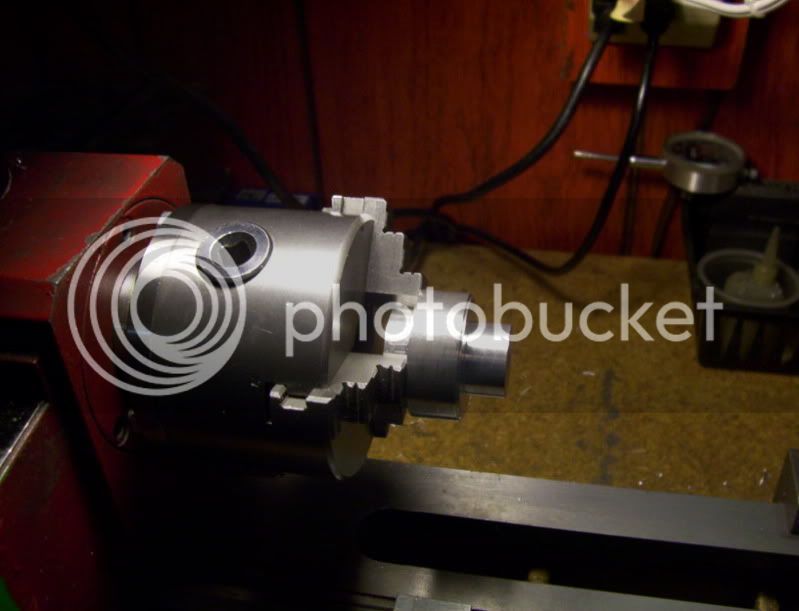

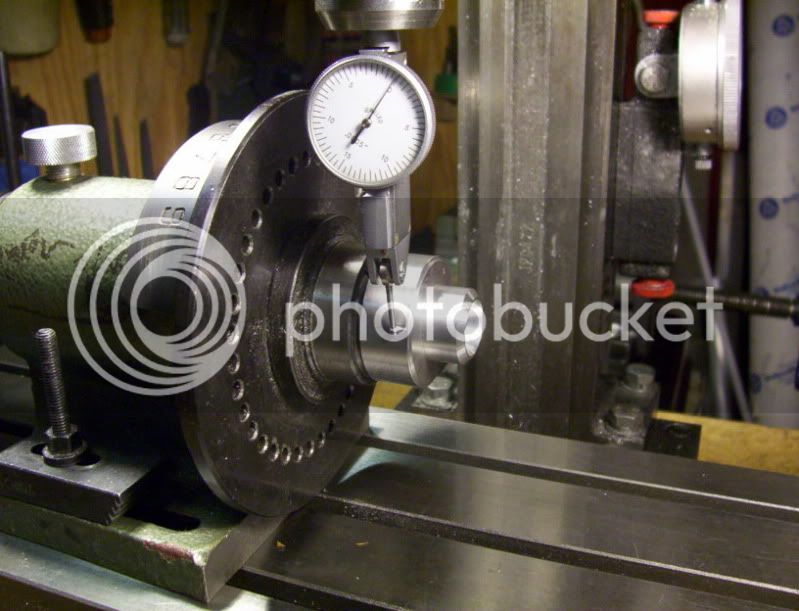

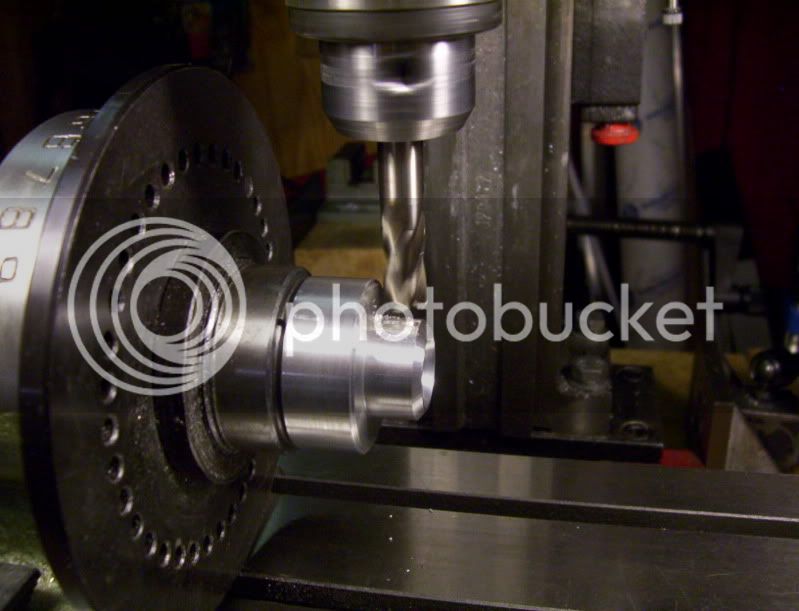

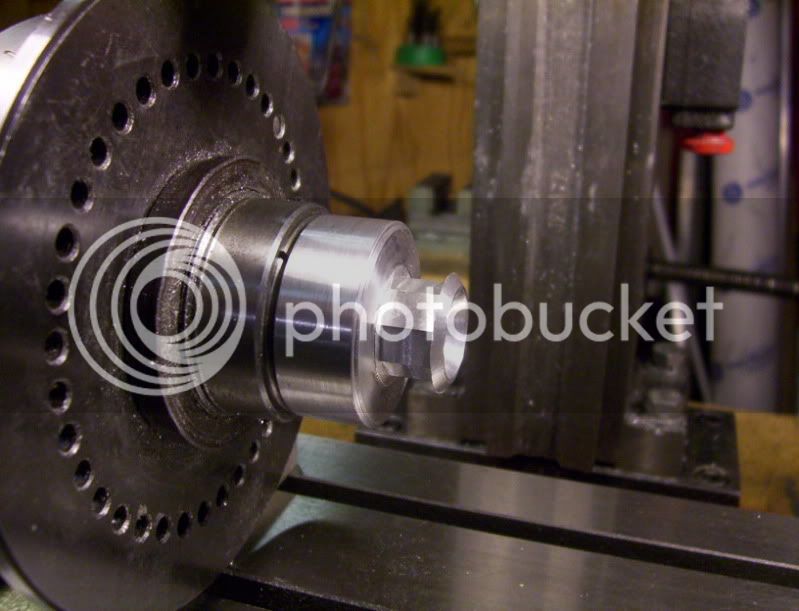

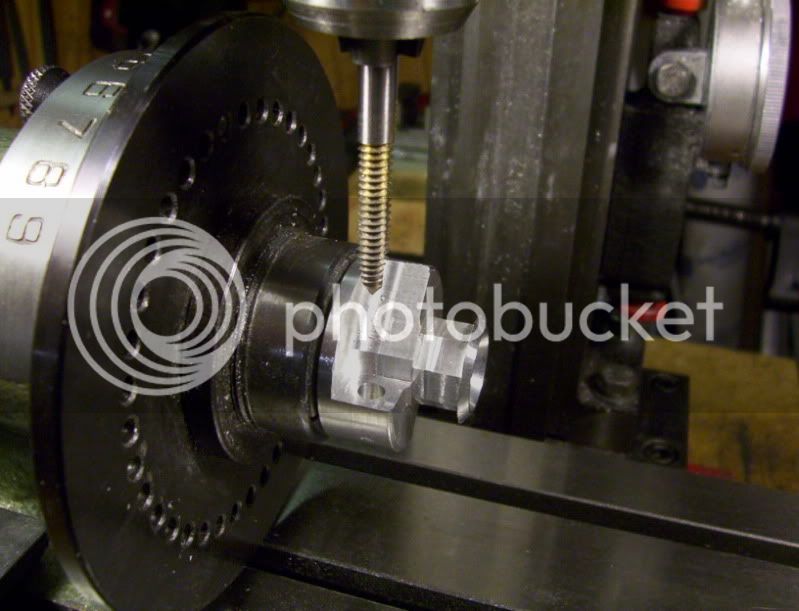

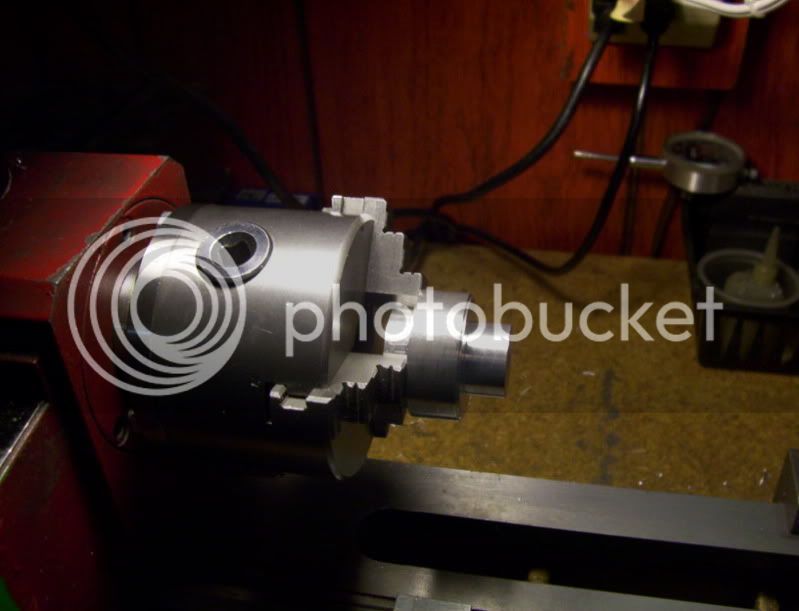

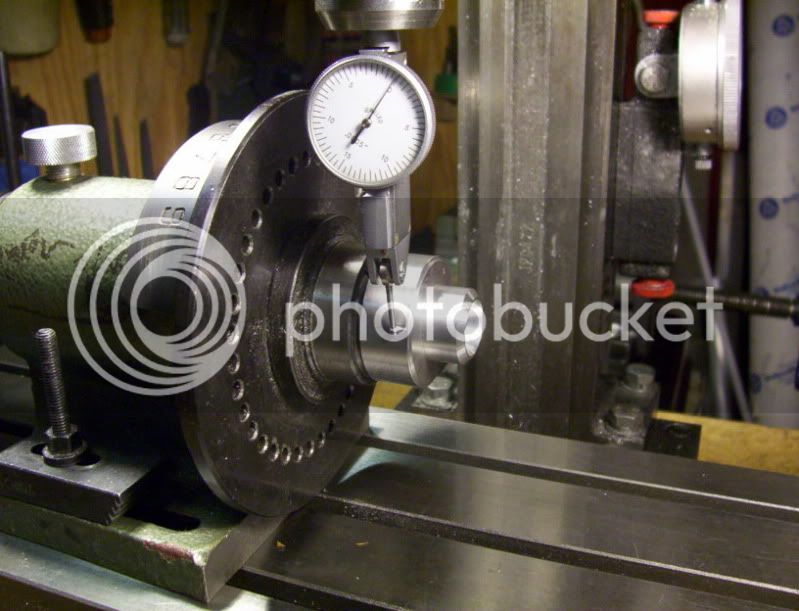

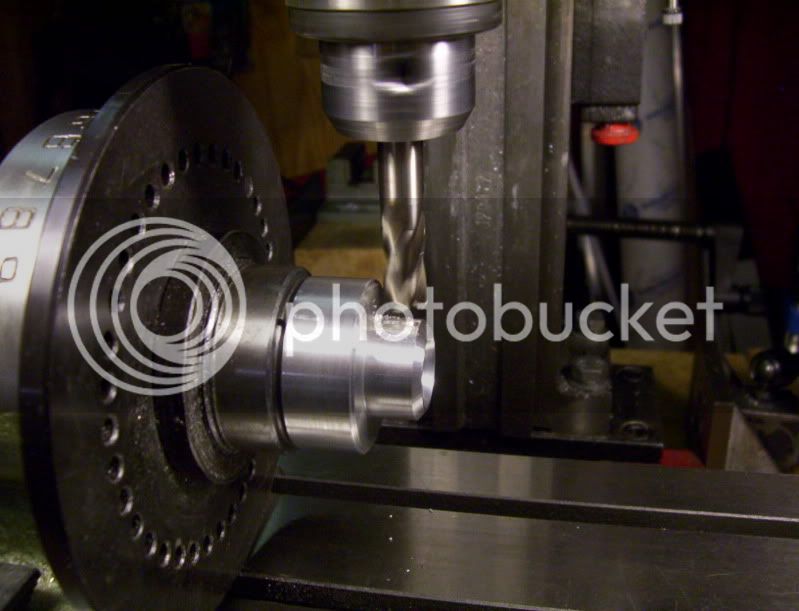

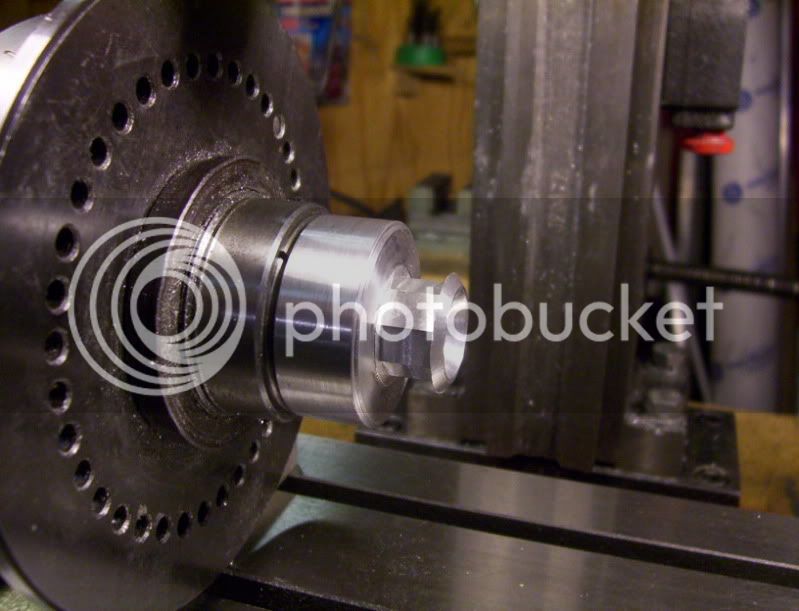

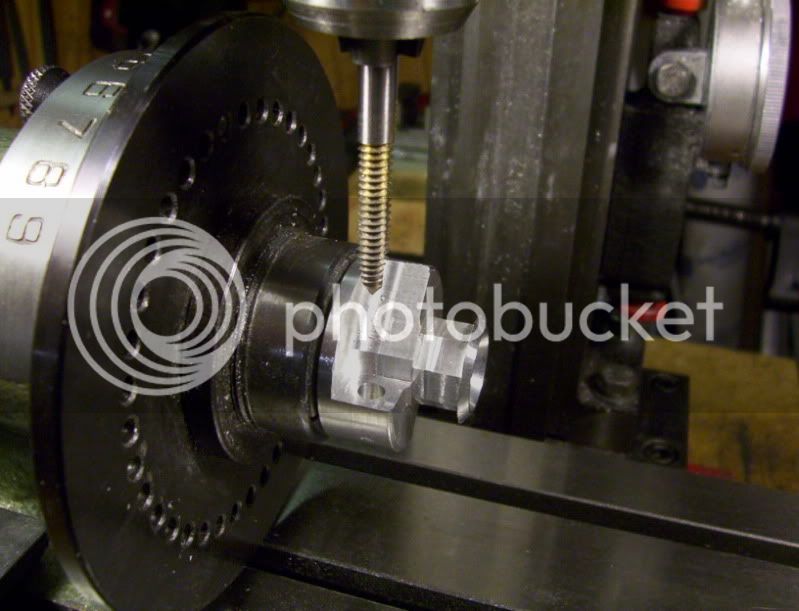

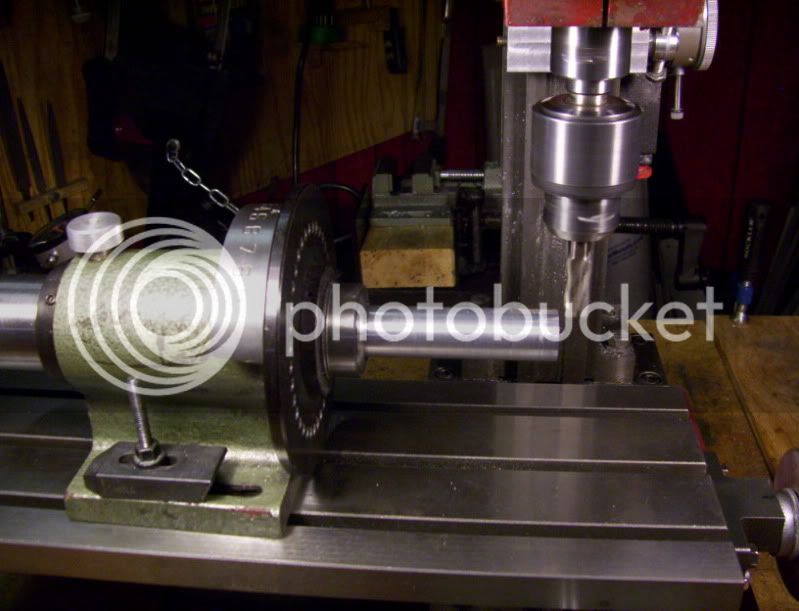

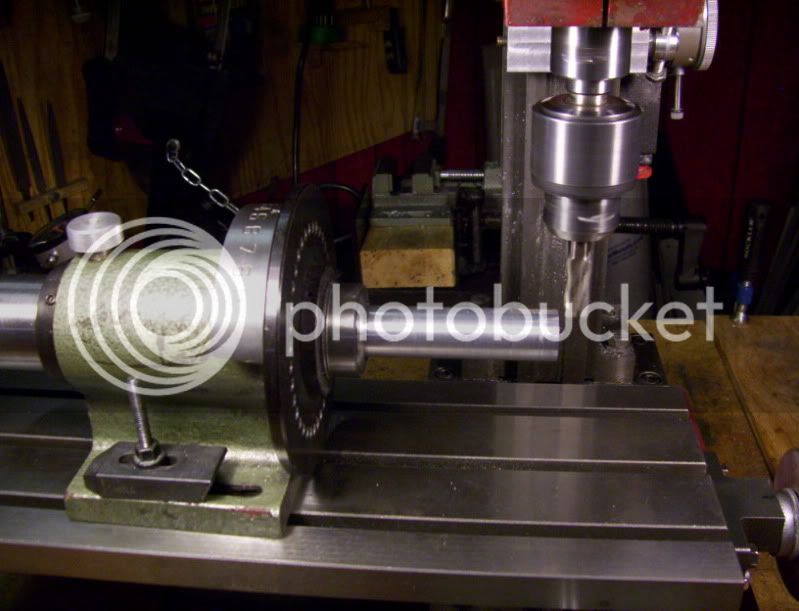

This is my work on the airintake manifold, I did today.

I started out with a piece of 1.5" dia. stock roughed out to 1.375" length.

I first machined a spigot to a 1" dia, by 3/8" long, to fit my 5C collet for my dividing head

where most of the work on it will take place.

Then turned it end for end to machine another spigot for the air intake stud.

Then began drilling and chamfer profiling, and tapping for 1/4-20 thread.

here it is befor the milling operation.

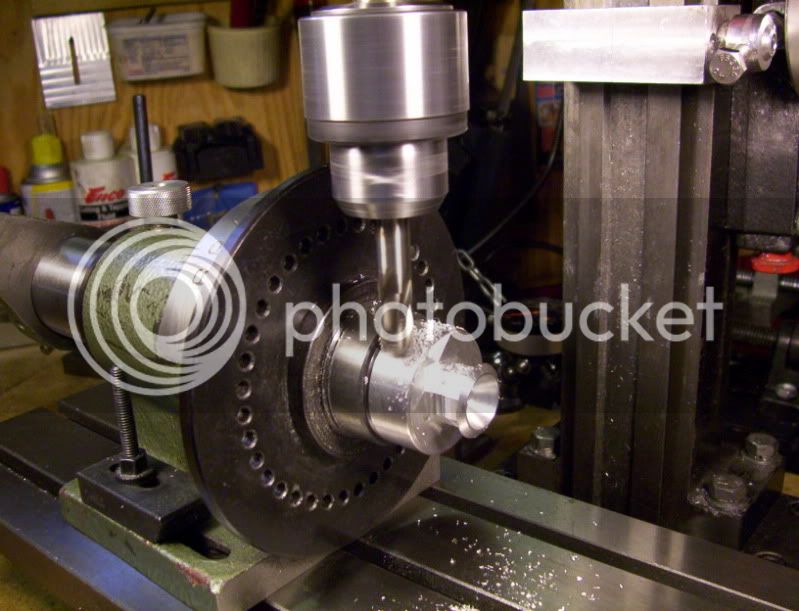

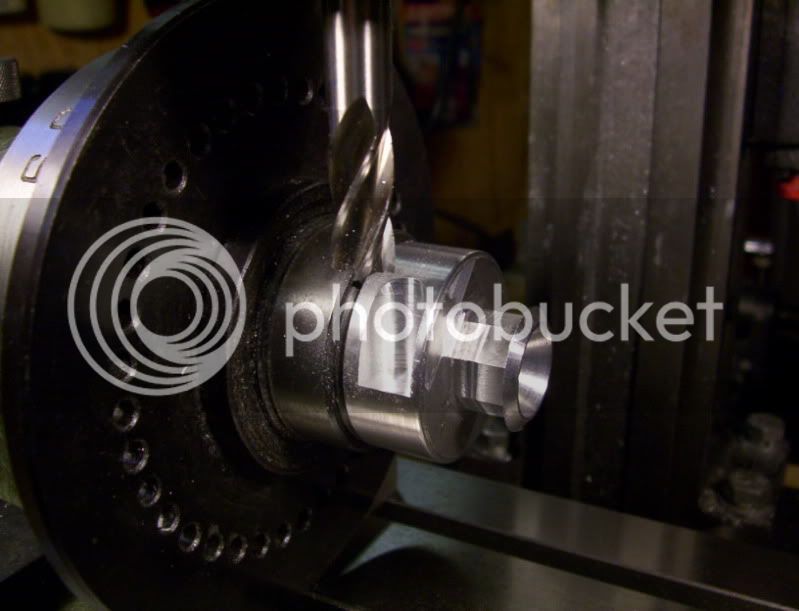

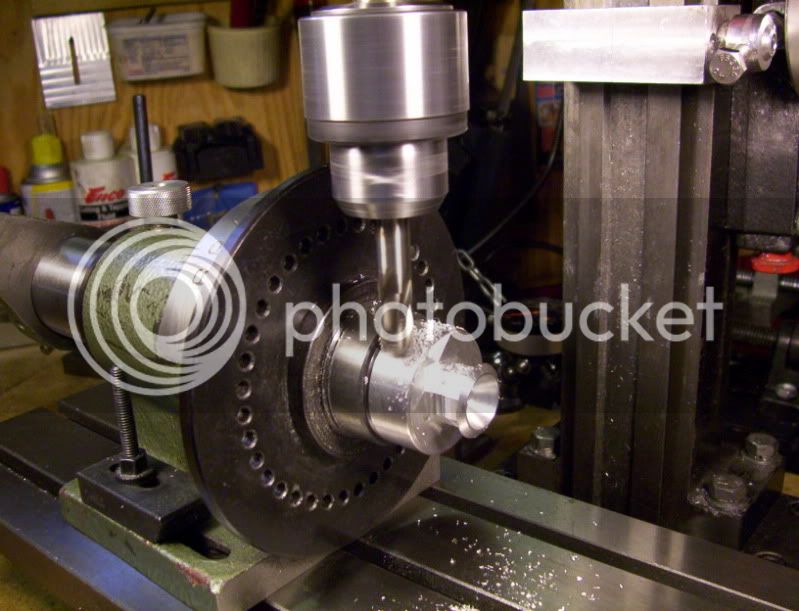

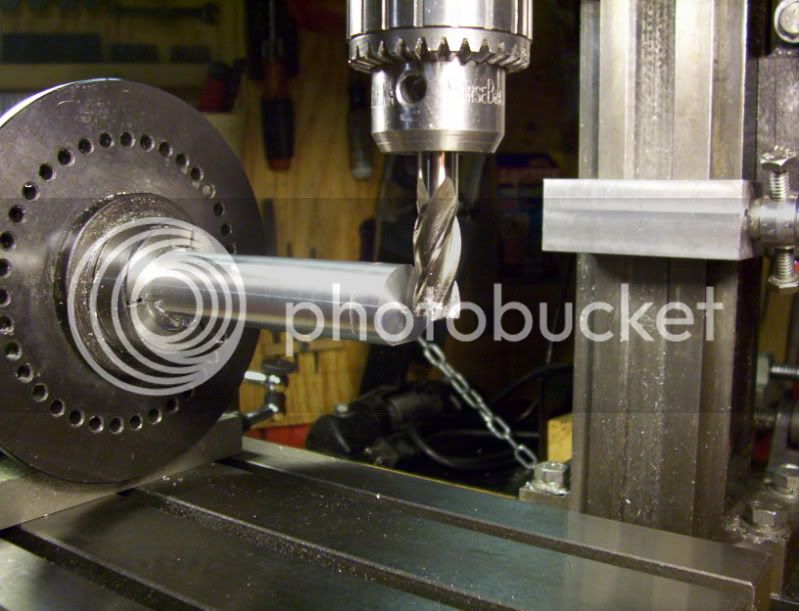

Now put it in my dividing head and begin the milling operations.

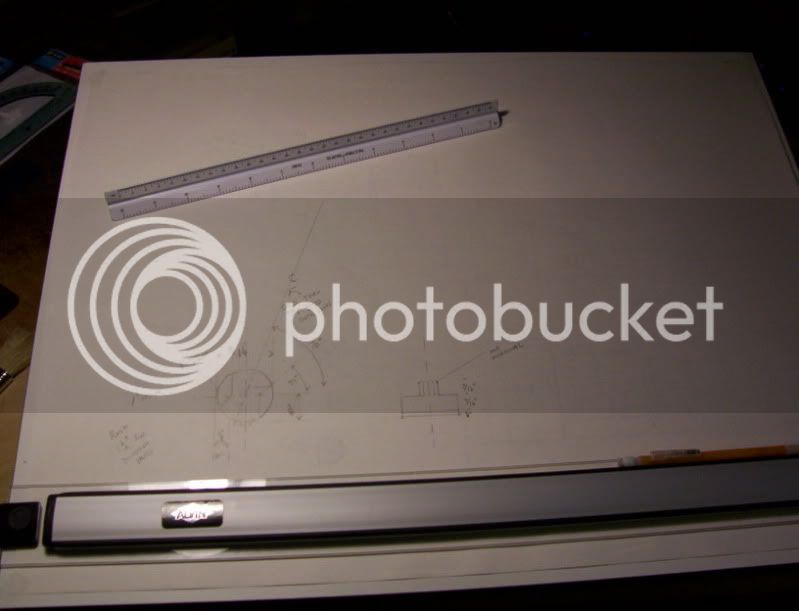

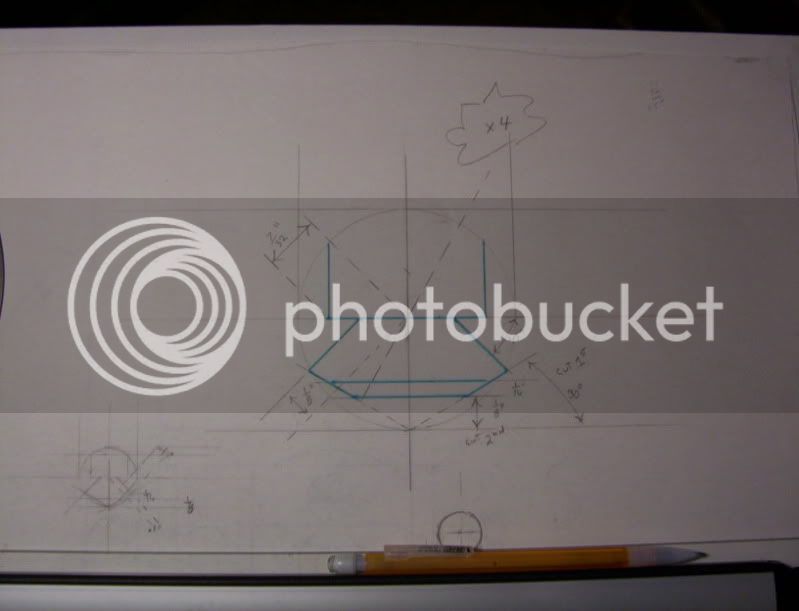

I take a look at my drawing, I did on my new drafting board at the dimensions I need to machine too,

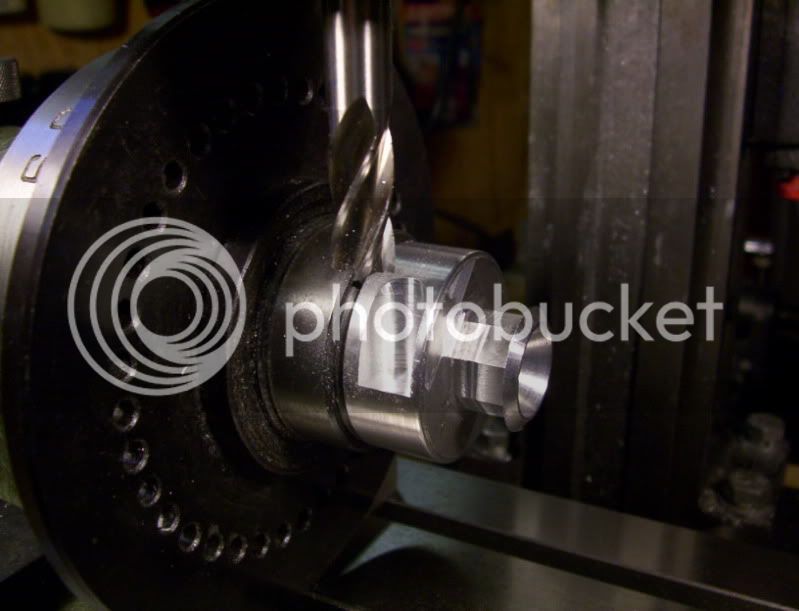

And now start the profile millings,

Now drill and tap for 1/4-20 threads

turn it 45* more for the front tapping,

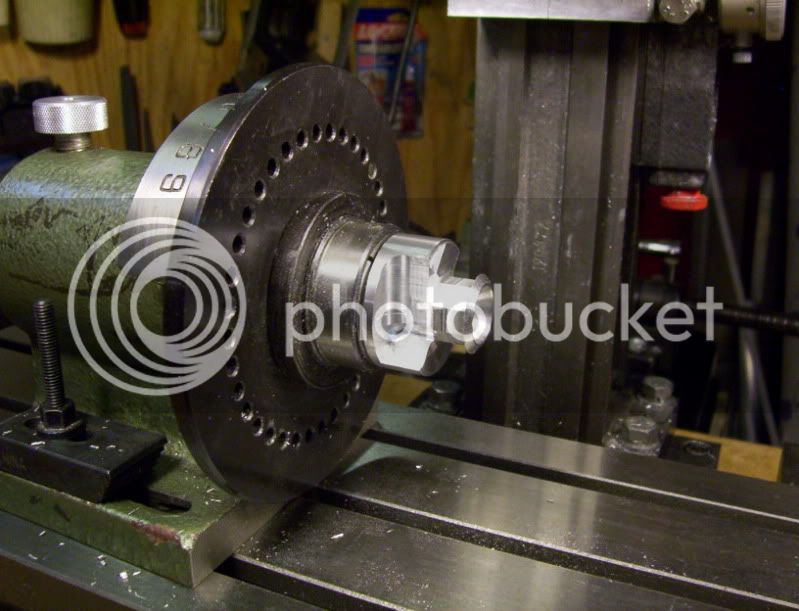

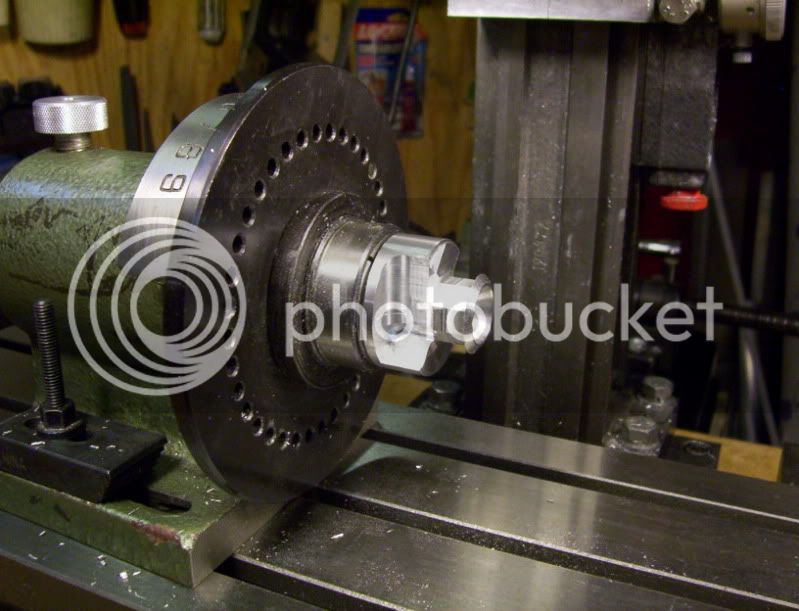

Here it is at this point, I need to make tube fittings for these threaded holes, next.

Thanks again...

I started out with a piece of 1.5" dia. stock roughed out to 1.375" length.

I first machined a spigot to a 1" dia, by 3/8" long, to fit my 5C collet for my dividing head

where most of the work on it will take place.

Then turned it end for end to machine another spigot for the air intake stud.

Then began drilling and chamfer profiling, and tapping for 1/4-20 thread.

here it is befor the milling operation.

Now put it in my dividing head and begin the milling operations.

I take a look at my drawing, I did on my new drafting board at the dimensions I need to machine too,

And now start the profile millings,

Now drill and tap for 1/4-20 threads

turn it 45* more for the front tapping,

Here it is at this point, I need to make tube fittings for these threaded holes, next.

Thanks again...

- Joined

- Dec 5, 2009

- Messages

- 510

- Reaction score

- 47

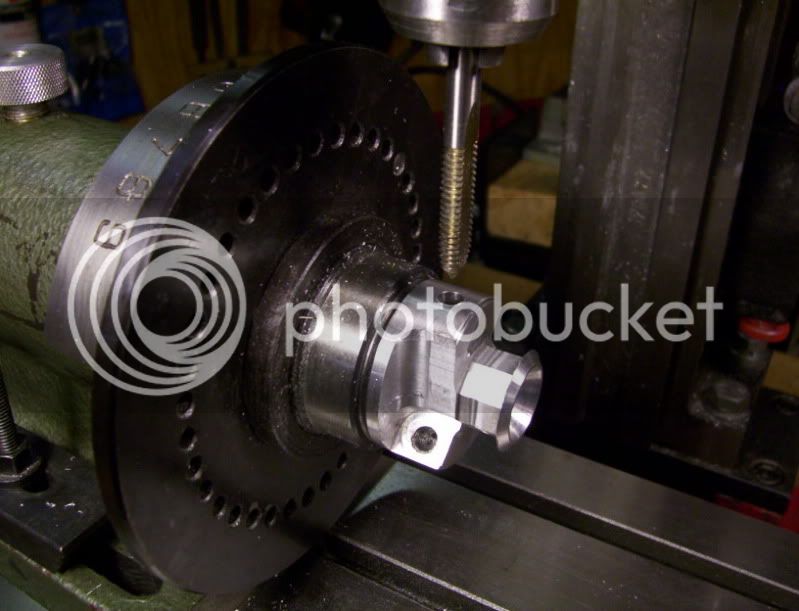

Hi,

Some more updates,

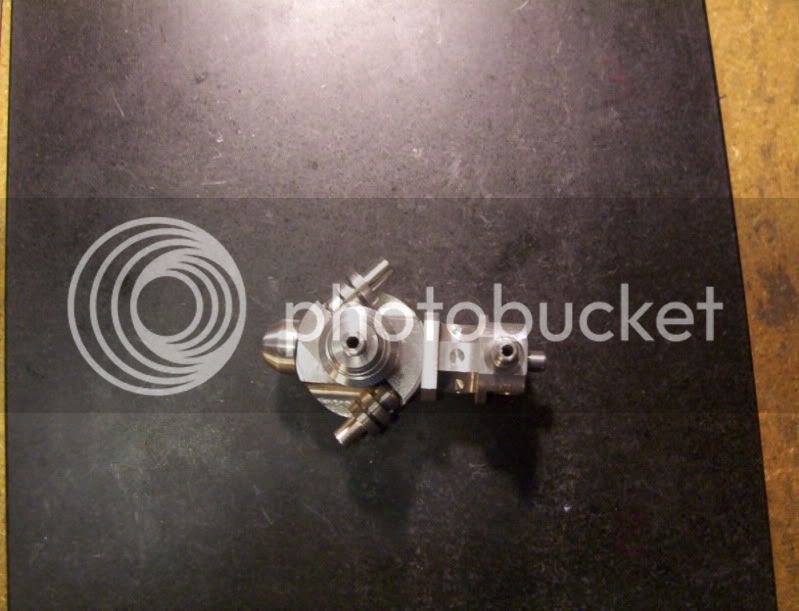

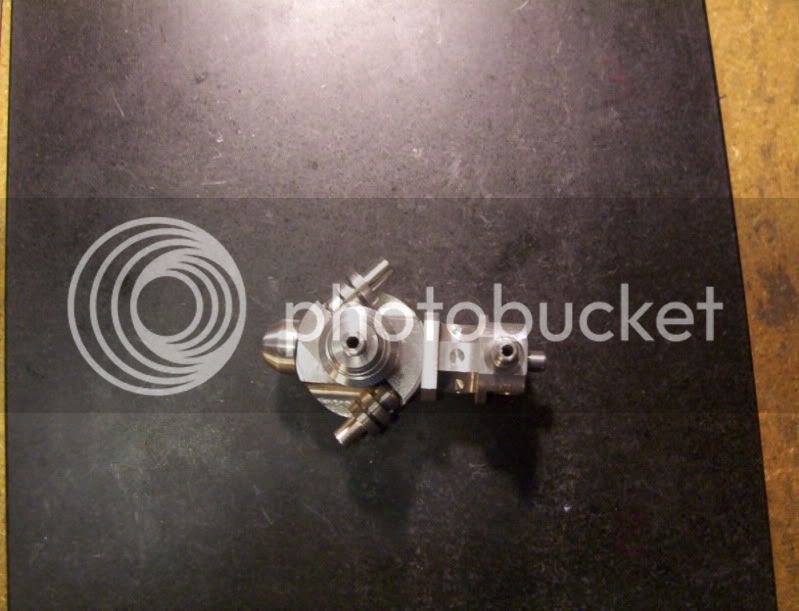

This is work on the Air Intake system.

I did this weekend.

The cylinder plumbing.

One section attached to the bank of left cylinders.

The Air Intake manifold.

Some more updates,

This is work on the Air Intake system.

I did this weekend.

The cylinder plumbing.

One section attached to the bank of left cylinders.

The Air Intake manifold.

- Joined

- Dec 28, 2008

- Messages

- 1,731

- Reaction score

- 9

Hi Hobby. Your build is progressing well. That's defiantly a unique design that can only come from a very creative imagination. Your builds display a menacing robotic theme with a futuristic style direction that's unlike anything I've seen before. I stared at the picture of it on the granite plate, and got freaked out a bit by the life like science fiction horror that emits from you project.

I meant the last sentence in a complimentary way. Its Art your creating, when it brings emotion to the surface of the admirer. Excellent work Hobby!

Thanks for posting your progress!

-MB

I meant the last sentence in a complimentary way. Its Art your creating, when it brings emotion to the surface of the admirer. Excellent work Hobby!

Thanks for posting your progress!

-MB

- Joined

- Dec 5, 2009

- Messages

- 510

- Reaction score

- 47

Hi,

You guys cracked me up, Rof}

Thanks for the compliments,

I never thought about it, until after you mentioned it, then when I went back and looked at the pics. That does look science fiction. I began to crack up laughing so hard, brought tears to my eyes, I was laughing so hard.

I had to post this one.

You guys cracked me up, Rof}

Thanks for the compliments,

I never thought about it, until after you mentioned it, then when I went back and looked at the pics. That does look science fiction. I began to crack up laughing so hard, brought tears to my eyes, I was laughing so hard.

I had to post this one.

.......You know it when you see it, the art in the mind of man transformed to metal! :bow: You have some serious concepts going on here Hobby............now will you have the next "Terminator IV" cyborg character done in time??

- Joined

- Dec 5, 2009

- Messages

- 510

- Reaction score

- 47

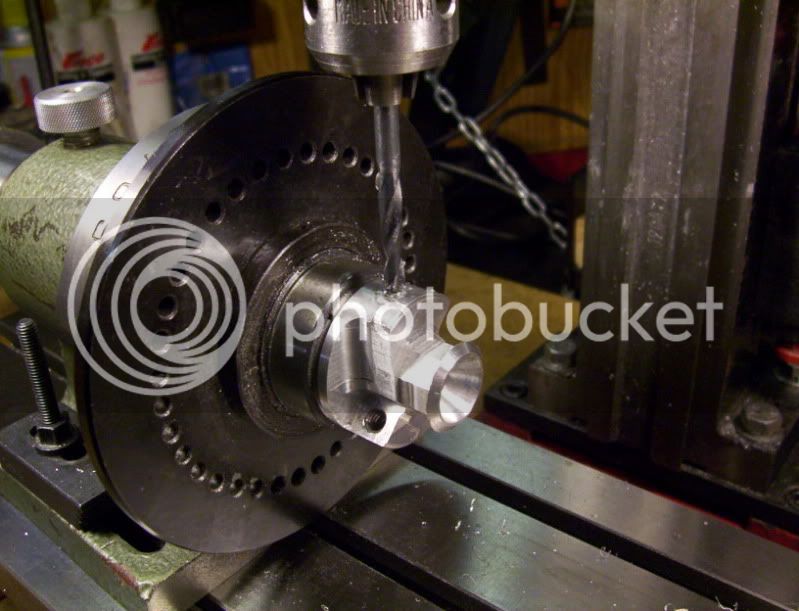

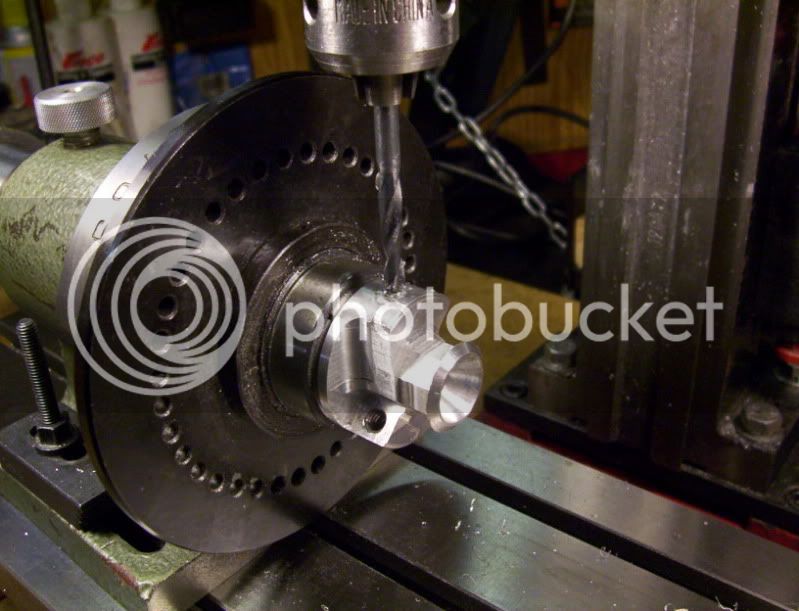

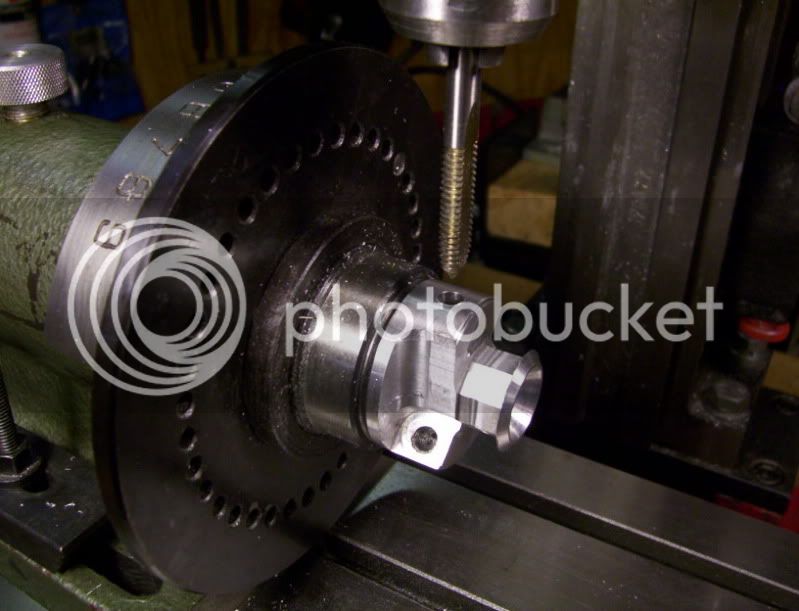

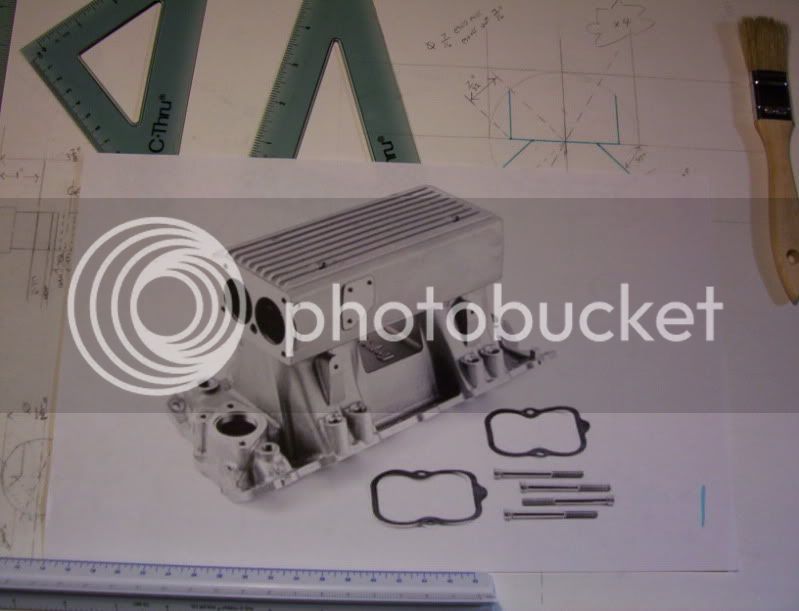

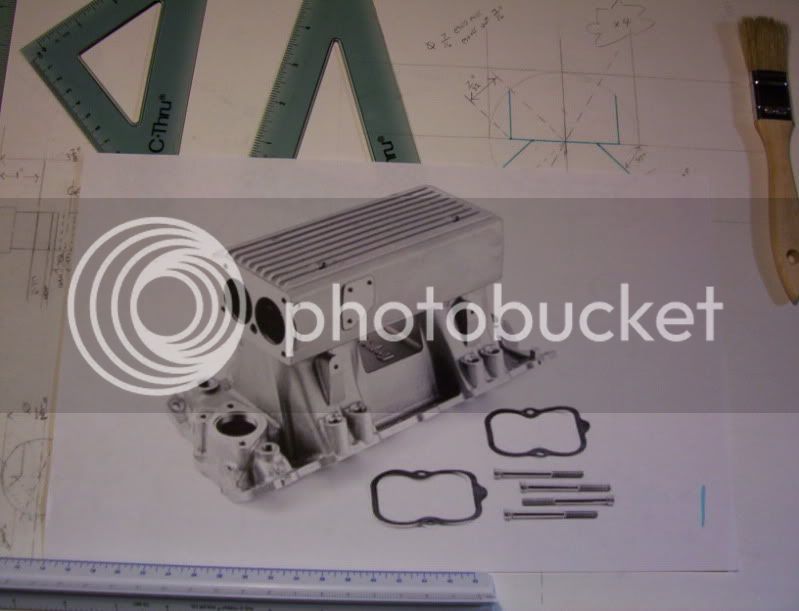

This was the original idea for the air intake system.

However the tubing is just too high of a loop, to work with my model engine.

I want to replace the tube with a solid machined workpiece, so I did a innerenet search for images of air intake manifolds, and after searching througha dozen or so, I found the exact one I was looking for, to use as a model for fabricating my own.

Here is what I found on the innenrnet.

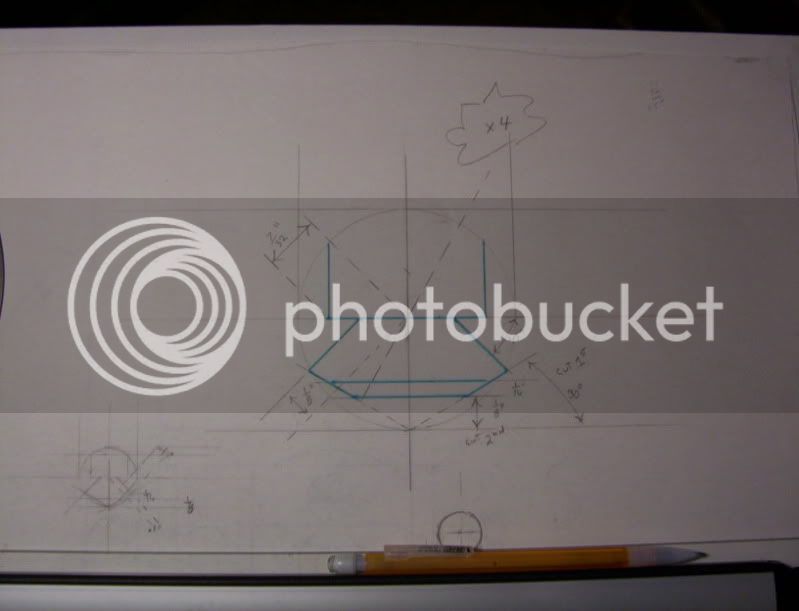

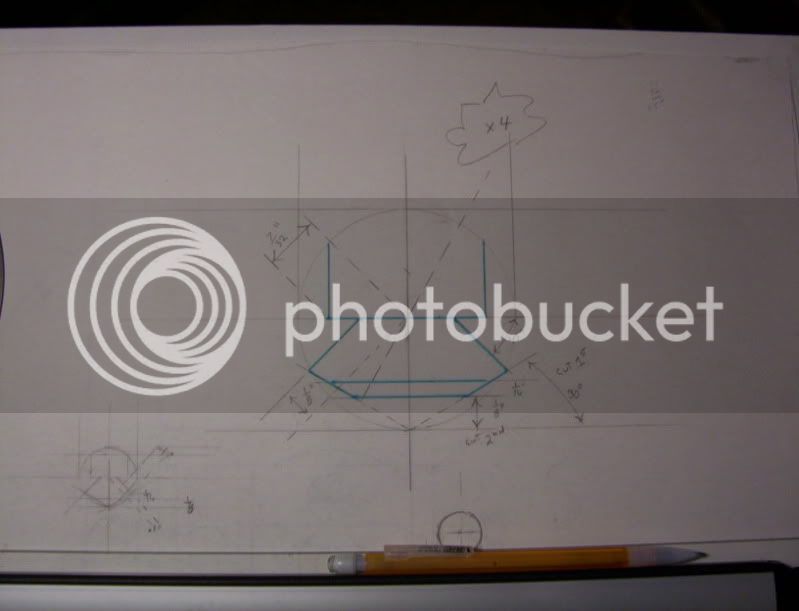

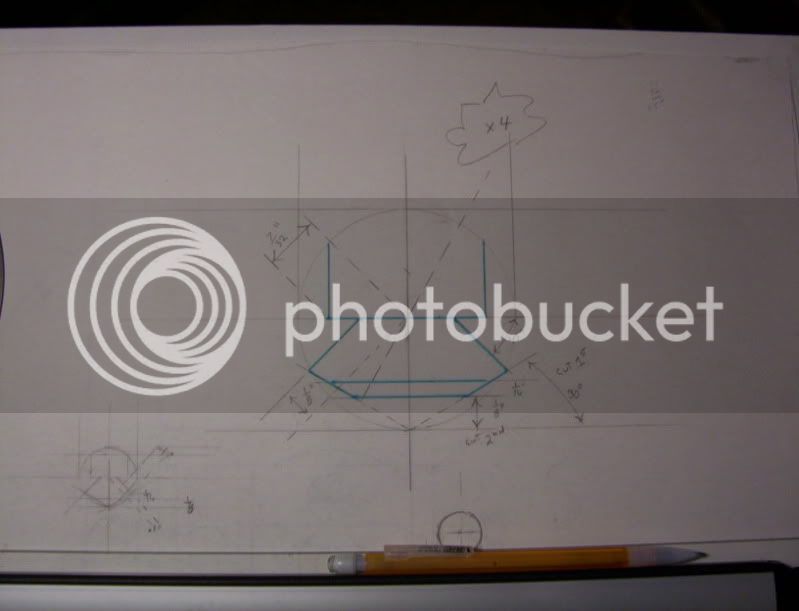

Now instead of CADing it, I get to use my new drafting board to draw this up with my own dimensions.

Since there is a few angles to mill at, I will use my 5C collet dividing head.

I want the whole workpiece to be made out of a 7/8" dia. round bar aluminum, so I used a 1" dia. bar, so I would have 1/8 clearancwe when I machine the profile on the back side towards the collet.

first up, cut a piece off of a 1" roundbar, then turn it to 7/8" dia. then set it up in the dividing head.

Now I have it set at 0* for the bottom side. I turn it 30* mill onw flat, then turn it 30* off of 0* the other direction to mill another flat, giving a "V" shape with an included angle of 60*.

Than I turn it back to 0*, to mill a third flat, and this will be the actual bottom surface, with 2 sides extending out at 30*

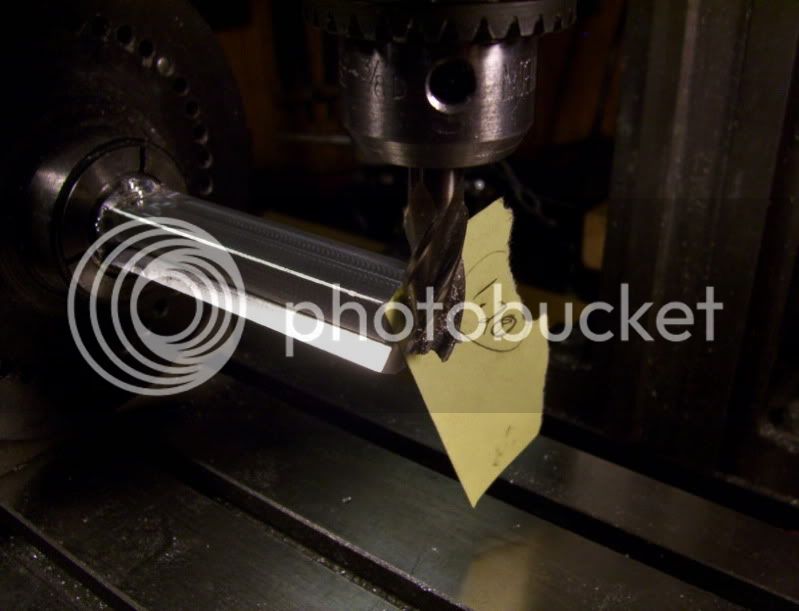

Now I turn it 180*, and this is now the top of the workpiece. From there I now turn it 45* to machine a shoulder, followed by a 45* dovetail cutter, to profile the middle of the workpiece. But first I need to establish the workpiece center. and locate the dimensions for machining.

Now to mill the top portion the sides first then the very top.

Now to set up and mill the front piece down to do the front profile.

Move in 5/16" to a depth of 1/2" to profile the front end .

That's all for now.

However the tubing is just too high of a loop, to work with my model engine.

I want to replace the tube with a solid machined workpiece, so I did a innerenet search for images of air intake manifolds, and after searching througha dozen or so, I found the exact one I was looking for, to use as a model for fabricating my own.

Here is what I found on the innenrnet.

Now instead of CADing it, I get to use my new drafting board to draw this up with my own dimensions.

Since there is a few angles to mill at, I will use my 5C collet dividing head.

I want the whole workpiece to be made out of a 7/8" dia. round bar aluminum, so I used a 1" dia. bar, so I would have 1/8 clearancwe when I machine the profile on the back side towards the collet.

first up, cut a piece off of a 1" roundbar, then turn it to 7/8" dia. then set it up in the dividing head.

Now I have it set at 0* for the bottom side. I turn it 30* mill onw flat, then turn it 30* off of 0* the other direction to mill another flat, giving a "V" shape with an included angle of 60*.

Than I turn it back to 0*, to mill a third flat, and this will be the actual bottom surface, with 2 sides extending out at 30*

Now I turn it 180*, and this is now the top of the workpiece. From there I now turn it 45* to machine a shoulder, followed by a 45* dovetail cutter, to profile the middle of the workpiece. But first I need to establish the workpiece center. and locate the dimensions for machining.

Now to mill the top portion the sides first then the very top.

Now to set up and mill the front piece down to do the front profile.

Move in 5/16" to a depth of 1/2" to profile the front end .

That's all for now.

Similar threads

- Replies

- 1

- Views

- 501

- Replies

- 2

- Views

- 927