LindsayWood

New Member

- Joined

- Jan 23, 2014

- Messages

- 4

- Reaction score

- 1

Hi,

Firstly, a quick introduction. I'm 19, from Australia and am now studying mech engineering. Always loved building things, built my first engine in metalwork class. I silver soldered the head together, making it unfixable when rust attacked the ball valve. I got my own lathe at 15 and spent many afternoons working on it and other metalwork projects- from art pieces to knives and puzzles. Even sold 3 or 4 pieces. For some reason I never undertook another engine past the stage of making a piston or two

Fast forward to now, and after finding John Tom's site I decided to pick up a little project to do in the afternoon (evening) after work during uni break. I redrew the #25 wobbler to suit my materials and metric tooling and completed it in two afternoons. It ran straight away, and a few small hiccups were fixed by some more lapping, lubricant and increased spring tension.

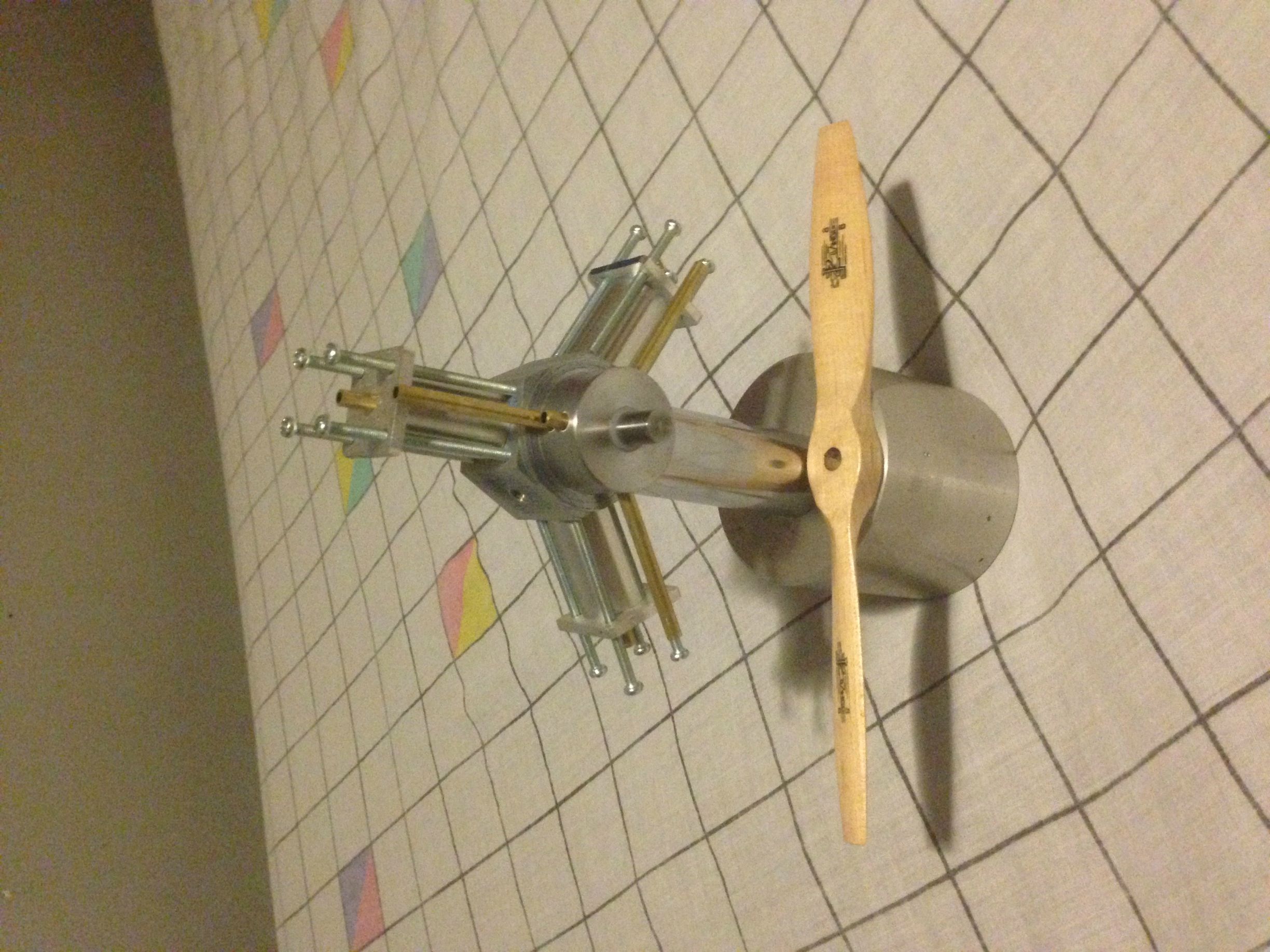

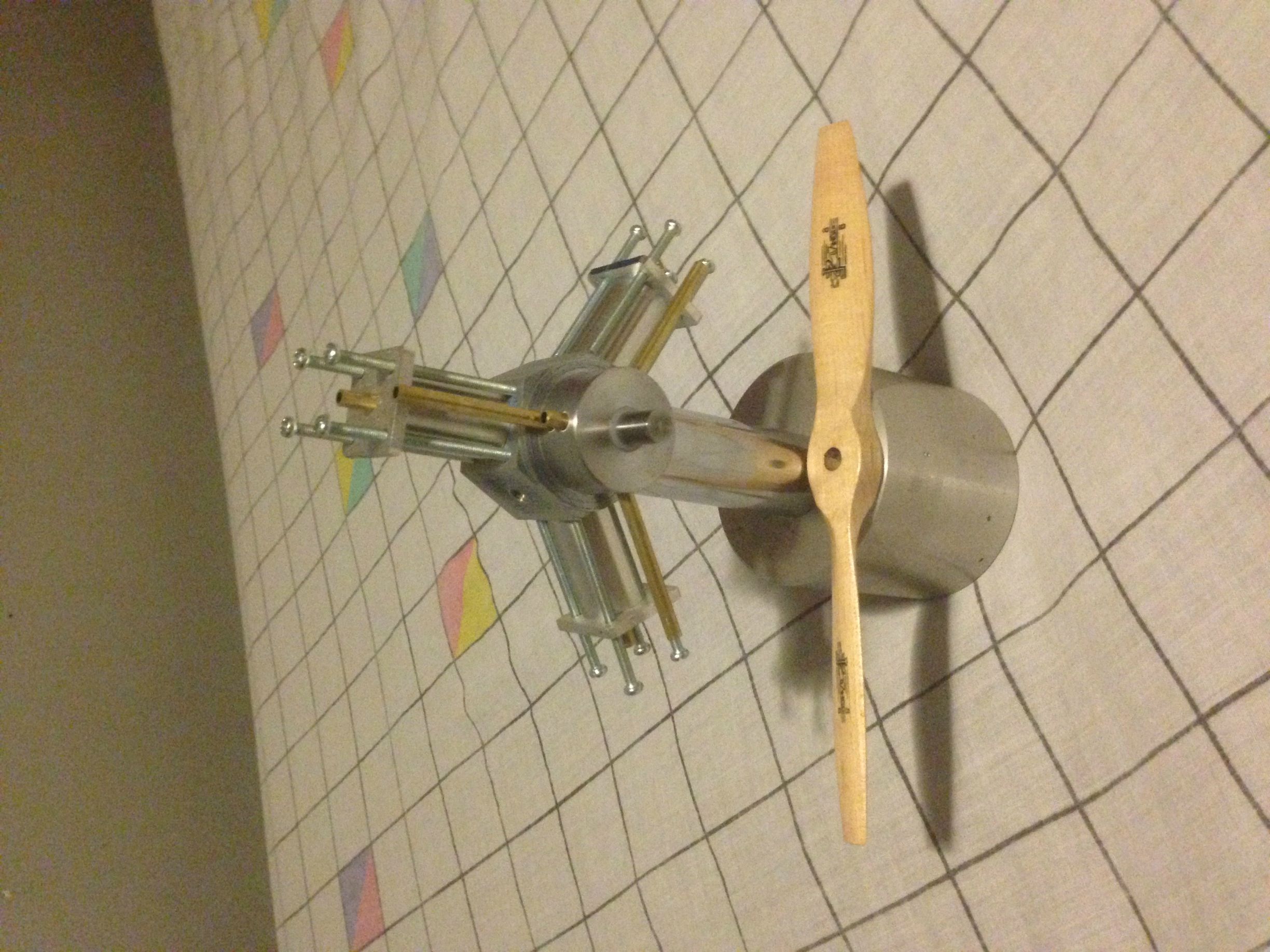

Wanting to build a more impressive engine, I started looking for plans (I try to minimise milling work as I only have a vertical mill slide which has poor rigidity and is annoying to deal with). I found Elmers #11 radial but wasn't a fan of the square cylinders and wanted to add my own touch so I redesigned the valving (inspired by Kerzel's rotary valve) and swapped the cylinders to round ones.

4 or so nights of work in and it's nearly there, needs some sanding and polishing, as well as trimming the bolts and loctiting/pressing things together. All turns nice and smoothly by hand at the moment. Another evening should complete it. Aluminium cylinders, block, heads and conrods with UHMW HDPE pistons, steel crank and hardened pins. Machining a hexagonal crankcase on the lathe mill slide was a PITA but worth it over using the 1.5" steel bar stock I had.

In the future I want to do larger cylinders with cooling fins (avoided it this time to save the milling work) with the air delivery tubes integrated into the cylinders, as well as cast iron liners with aluminium pistons. I'll probably end up starting a new engine as soon as this one runs though, I think I'm addicted now!

I've operated the valves by hand and they deliver a lot of air almost completely through the power stroke and exhaust the entire return stroke. Combined with a 5/8" bore * 1/2" stroke it should be a quick engine with lots of power. I got a prop for display purposes but the engine is setup to run the wrong way for it- swapping the crank pin to the other side will fix that though.

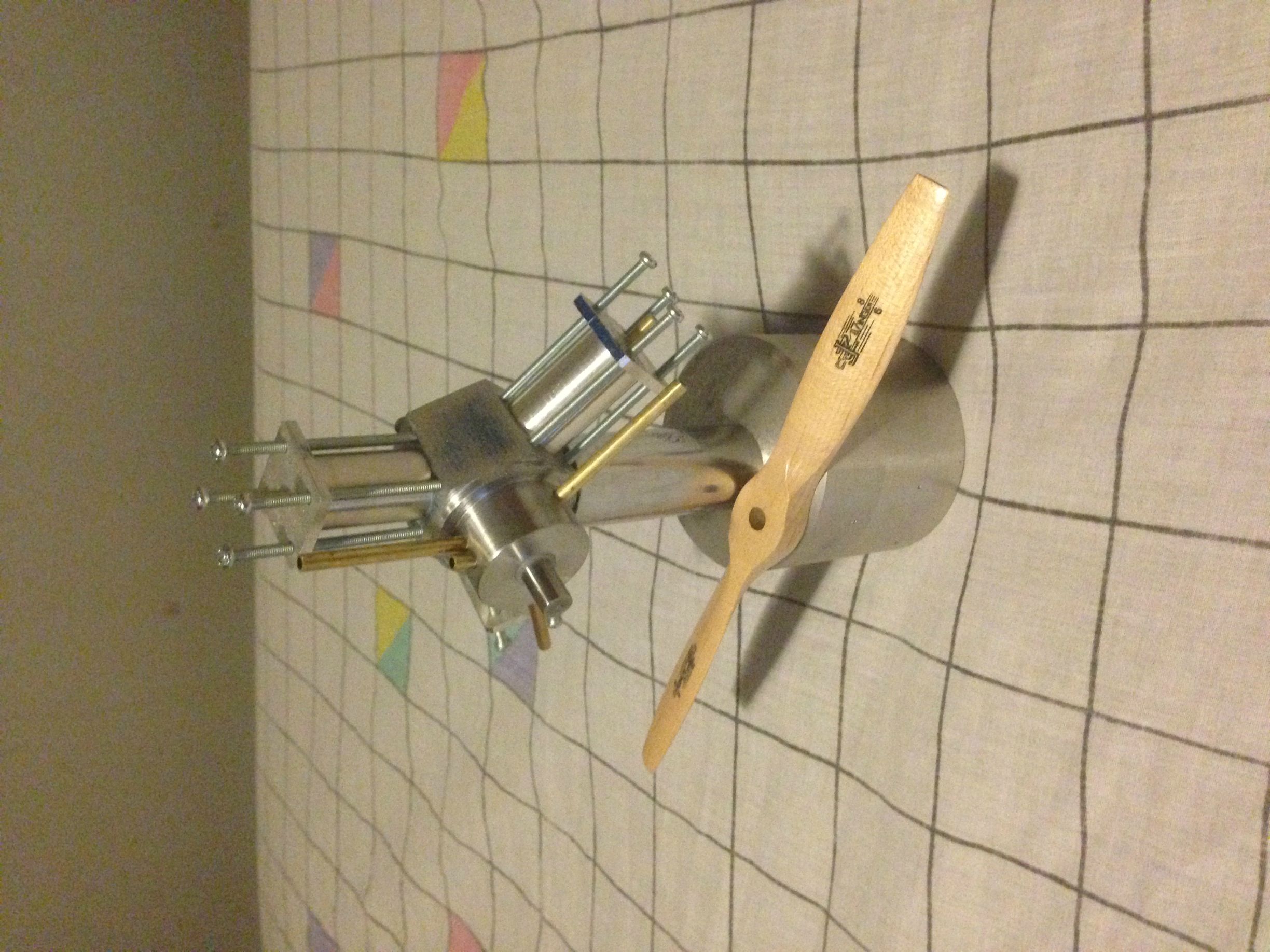

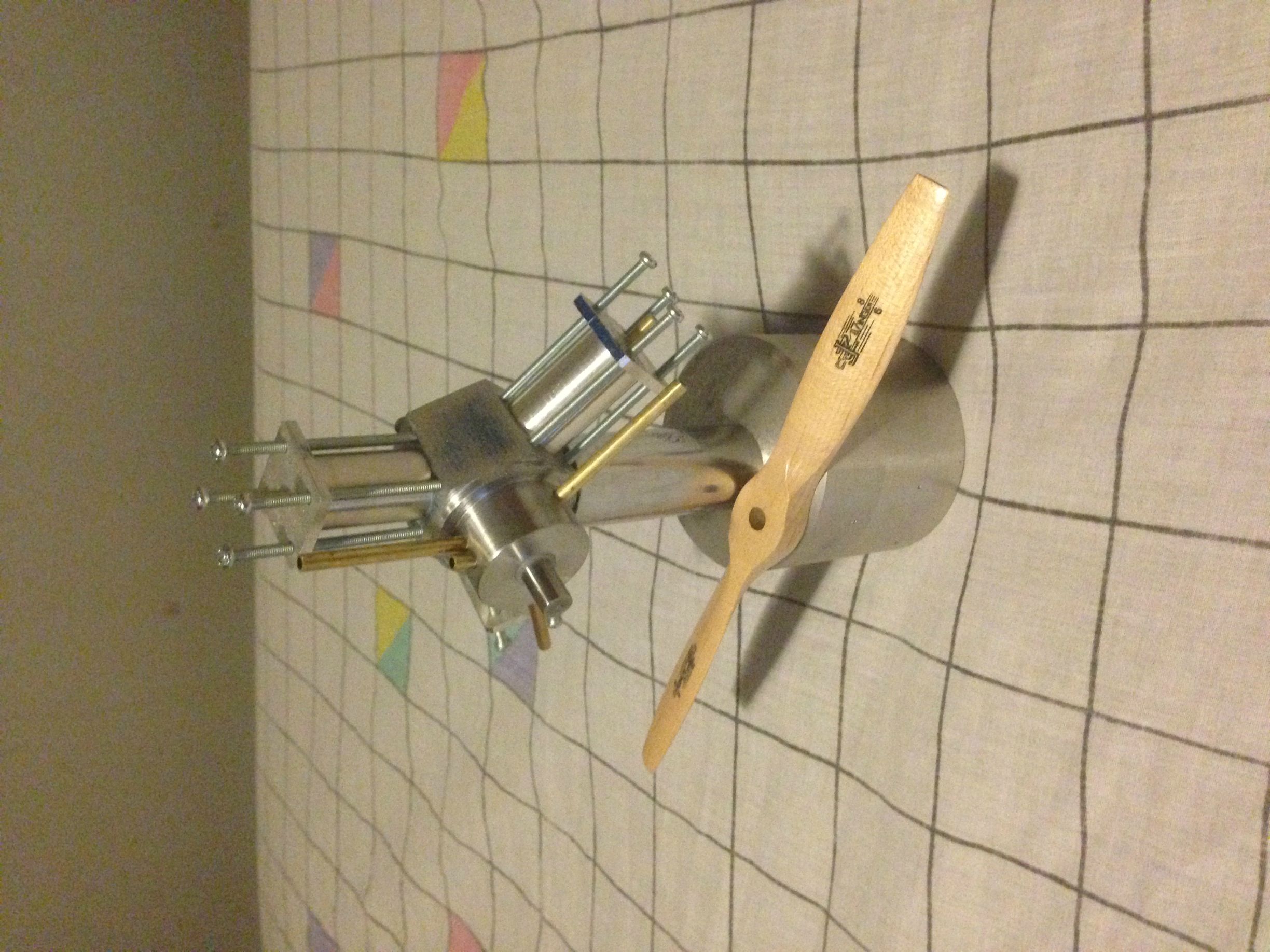

The blue is layout dye showing spots that need more sanding work before polishing. The screws will all be SHCS or tie rods once I make a trip to Coventrys for some fasteners.

Firstly, a quick introduction. I'm 19, from Australia and am now studying mech engineering. Always loved building things, built my first engine in metalwork class. I silver soldered the head together, making it unfixable when rust attacked the ball valve. I got my own lathe at 15 and spent many afternoons working on it and other metalwork projects- from art pieces to knives and puzzles. Even sold 3 or 4 pieces. For some reason I never undertook another engine past the stage of making a piston or two

Fast forward to now, and after finding John Tom's site I decided to pick up a little project to do in the afternoon (evening) after work during uni break. I redrew the #25 wobbler to suit my materials and metric tooling and completed it in two afternoons. It ran straight away, and a few small hiccups were fixed by some more lapping, lubricant and increased spring tension.

Wanting to build a more impressive engine, I started looking for plans (I try to minimise milling work as I only have a vertical mill slide which has poor rigidity and is annoying to deal with). I found Elmers #11 radial but wasn't a fan of the square cylinders and wanted to add my own touch so I redesigned the valving (inspired by Kerzel's rotary valve) and swapped the cylinders to round ones.

4 or so nights of work in and it's nearly there, needs some sanding and polishing, as well as trimming the bolts and loctiting/pressing things together. All turns nice and smoothly by hand at the moment. Another evening should complete it. Aluminium cylinders, block, heads and conrods with UHMW HDPE pistons, steel crank and hardened pins. Machining a hexagonal crankcase on the lathe mill slide was a PITA but worth it over using the 1.5" steel bar stock I had.

In the future I want to do larger cylinders with cooling fins (avoided it this time to save the milling work) with the air delivery tubes integrated into the cylinders, as well as cast iron liners with aluminium pistons. I'll probably end up starting a new engine as soon as this one runs though, I think I'm addicted now!

I've operated the valves by hand and they deliver a lot of air almost completely through the power stroke and exhaust the entire return stroke. Combined with a 5/8" bore * 1/2" stroke it should be a quick engine with lots of power. I got a prop for display purposes but the engine is setup to run the wrong way for it- swapping the crank pin to the other side will fix that though.

The blue is layout dye showing spots that need more sanding work before polishing. The screws will all be SHCS or tie rods once I make a trip to Coventrys for some fasteners.