Hi to all

I haven't post in a while, but I still follow the forum periodically!

Rigth now Im making some small tools that I will need in the future, and one of those a inside micrometer, I have a spare import micrometer that Im trying to rip a part, the goal is to separate the frame from the mic head, and put a new frame with the proper anvil to measure the tickness of the wall of a tube shaped piece.

that way if I know the OD of the piece and the tickness of the wall I can get the bore diameter.

but I cant get the frame out, I get a shot with a dremel to weak the union, thinking that was a press-fit type but no luck in that, before I totally destroy the poor micrometer, is posible to do this?

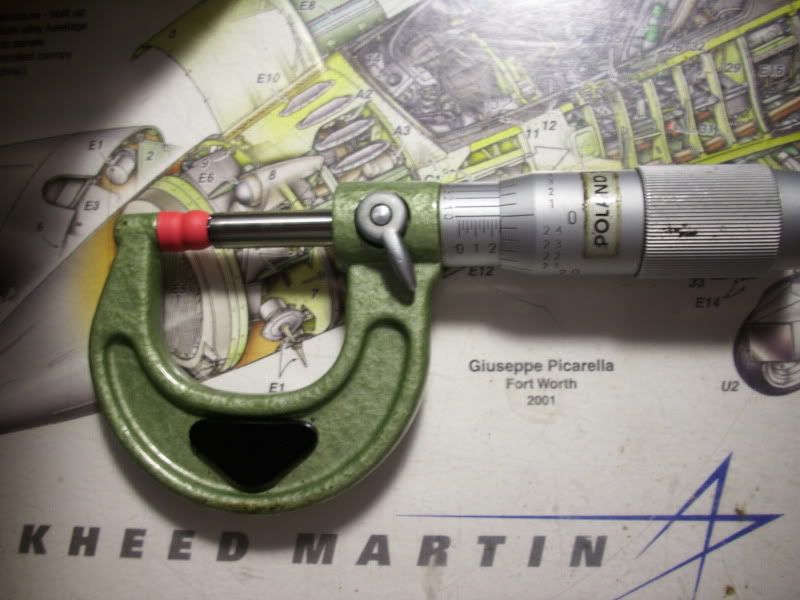

My micrometer is like this one

And I want to turn it intro something like this:

???

Saludos!

I haven't post in a while, but I still follow the forum periodically!

Rigth now Im making some small tools that I will need in the future, and one of those a inside micrometer, I have a spare import micrometer that Im trying to rip a part, the goal is to separate the frame from the mic head, and put a new frame with the proper anvil to measure the tickness of the wall of a tube shaped piece.

that way if I know the OD of the piece and the tickness of the wall I can get the bore diameter.

but I cant get the frame out, I get a shot with a dremel to weak the union, thinking that was a press-fit type but no luck in that, before I totally destroy the poor micrometer, is posible to do this?

My micrometer is like this one

And I want to turn it intro something like this:

???

Saludos!