Is this the beginning of a team effort??

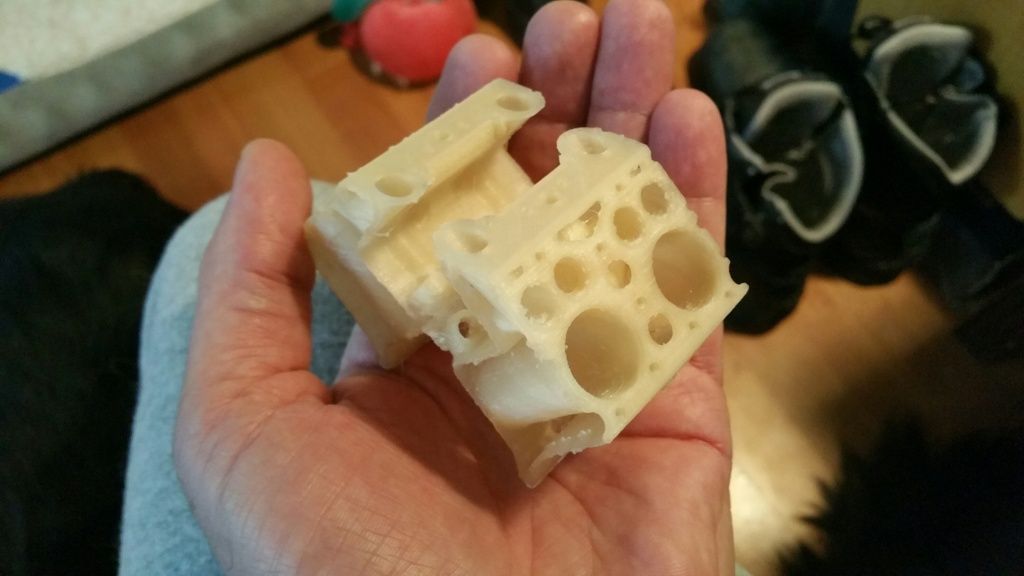

I get like a dog on a bone when I start something. Ordering an Objet 30 Pro tomorrow, trying to find existing 1/4 scale spark plugs, figuring out how to hot forge valves, getting my wax printer running and I've reached the point where I can see a completed running 1/4 scale Flathead Ford engine as attainable. Wish there were an existing 1/4 scale Stromberg carburetor. Could be fed propane or liquid fuel via a remote hidden single injector run off my Megasquirt.

Flat32:fan:

I get like a dog on a bone when I start something. Ordering an Objet 30 Pro tomorrow, trying to find existing 1/4 scale spark plugs, figuring out how to hot forge valves, getting my wax printer running and I've reached the point where I can see a completed running 1/4 scale Flathead Ford engine as attainable. Wish there were an existing 1/4 scale Stromberg carburetor. Could be fed propane or liquid fuel via a remote hidden single injector run off my Megasquirt.

Flat32:fan: