Metal Mickey

Well-Known Member

- Joined

- Jul 5, 2008

- Messages

- 612

- Reaction score

- 6

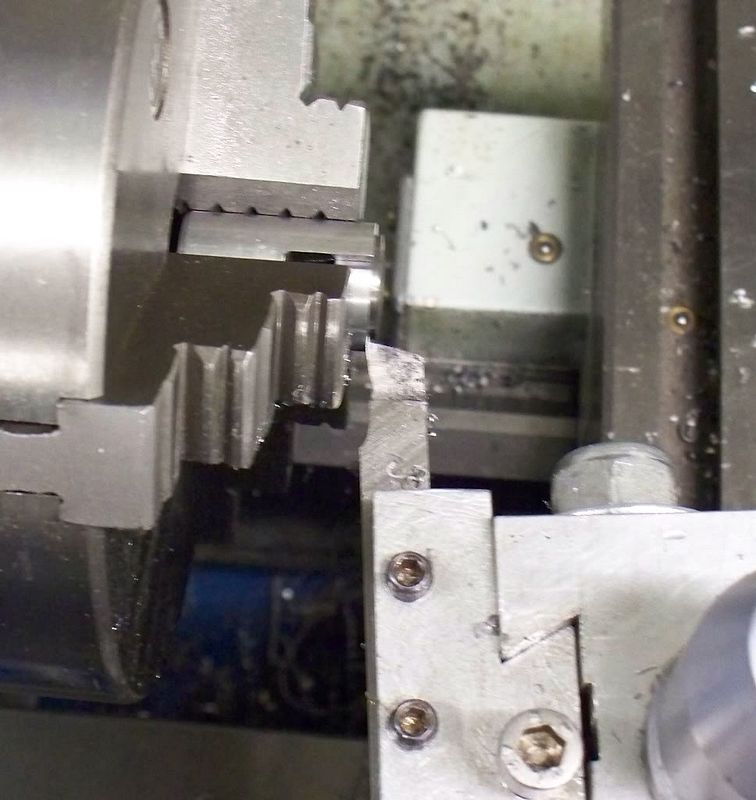

Well I started to set up the procedures for cutting the cams today. To keep the post short I have a more detailed description on my blog or website http:www.mikes-models.com/blog or http:www.mikes-models.com/ however suffice to say I made the first practice blank OK and down to size. The turning fixture was simple enough and cutting the first cuts to get the minimum diameter also seemed to work.

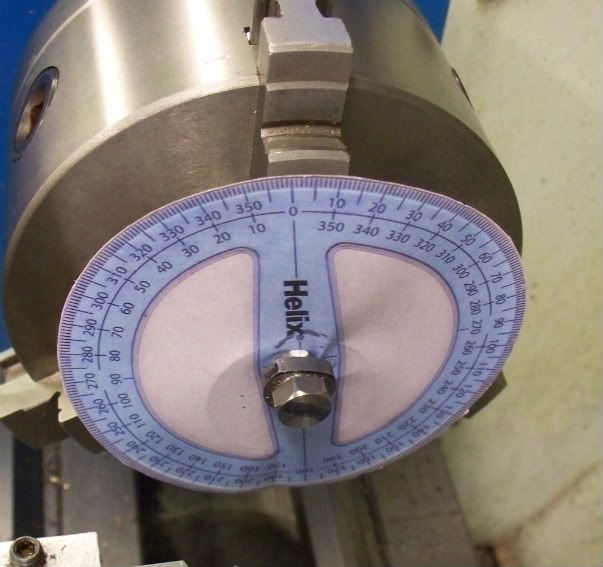

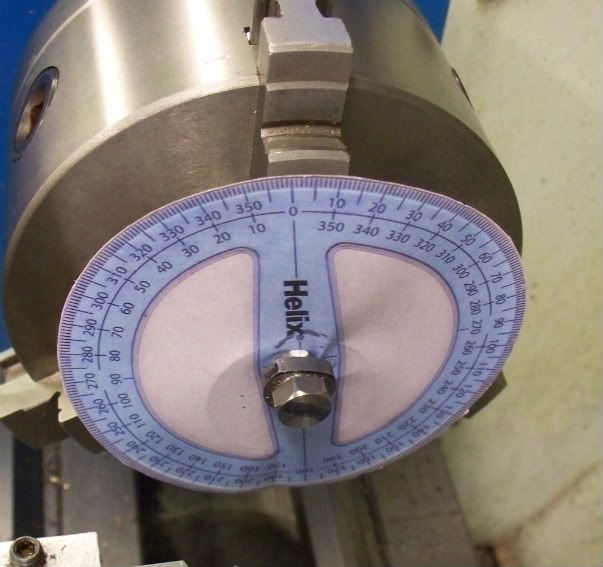

However I mucked up when it cam to moving it around as per instructions of between 5 and 10deg. I moved the fixture instead of the cam! :'( However after a little recovery and further thought on how to manage the turning of between 5 and 10 degree I hit upon the idea of photocopying a 360 degree protractor I have. With a little white correction fluid on the cam and a light scribe mark, the position of the cam in relation to the chart should be OK. Tomorrow time will tell!

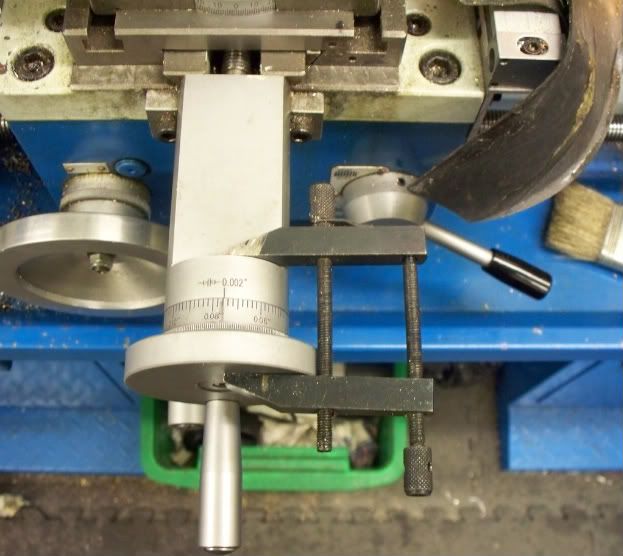

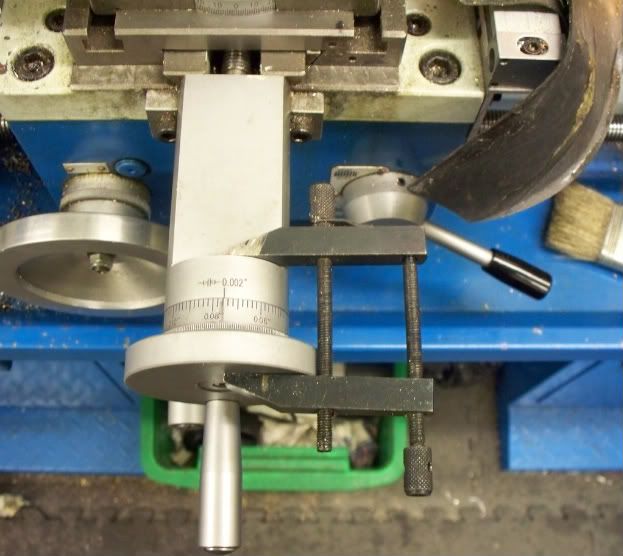

However one question if you can help. The turning of the cams requires the cross slide to be secured at the correct position. I have looked on my cross slide but do not see an obvious method. So I have improvised as in the photo below. Is this the best way, or am I missing something?

However I mucked up when it cam to moving it around as per instructions of between 5 and 10deg. I moved the fixture instead of the cam! :'( However after a little recovery and further thought on how to manage the turning of between 5 and 10 degree I hit upon the idea of photocopying a 360 degree protractor I have. With a little white correction fluid on the cam and a light scribe mark, the position of the cam in relation to the chart should be OK. Tomorrow time will tell!

However one question if you can help. The turning of the cams requires the cross slide to be secured at the correct position. I have looked on my cross slide but do not see an obvious method. So I have improvised as in the photo below. Is this the best way, or am I missing something?