Powder keg

Well-Known Member

- Joined

- Oct 10, 2007

- Messages

- 1,091

- Reaction score

- 3

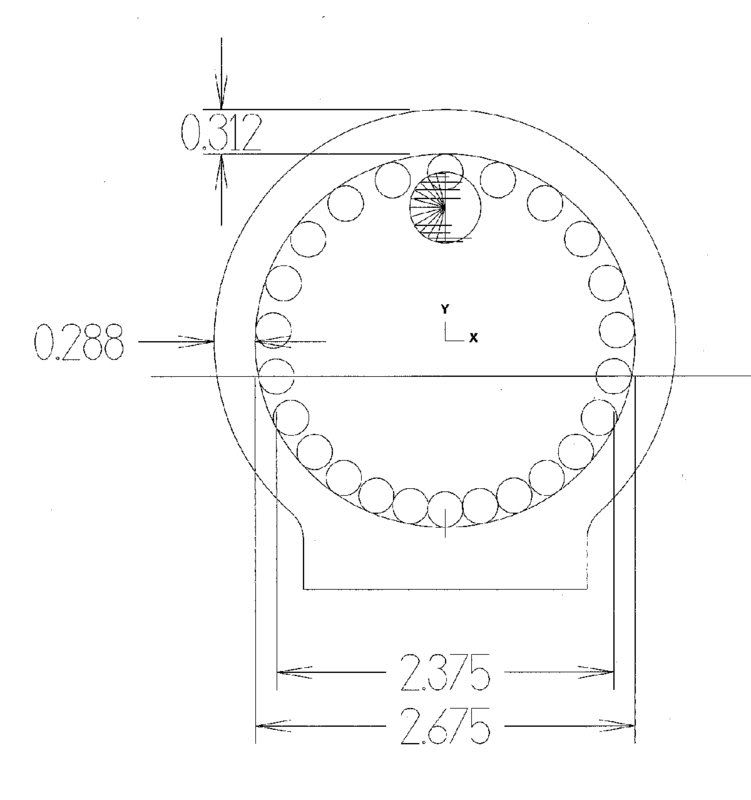

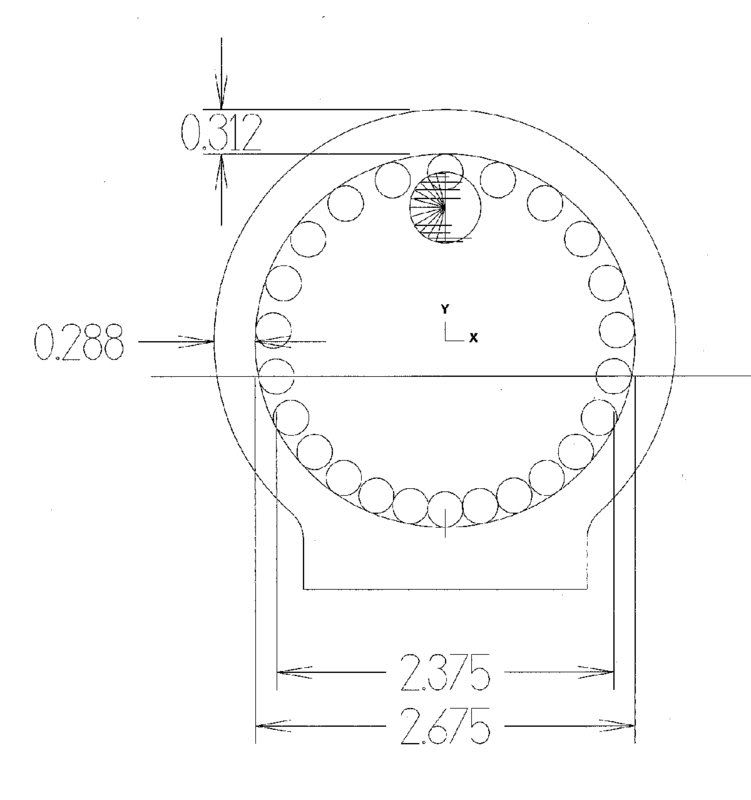

Well, I decided to see if I could figure out this crazy cam ring. It took me a bit to get my head around it and figure out how to draw it. But I think everything turned out OK? I printed it out and scanned the image. Here it is. From this I have a piece of aluminum plate that I can make one of these 3X bigger )

)

I just have to scale it up and do a toolpath on it. I drew it up with Mastercam. The hard part was the line that the rollers roll on. I had a heck of a time getting it tangent with the rollers.

Later, Wes

I just have to scale it up and do a toolpath on it. I drew it up with Mastercam. The hard part was the line that the rollers roll on. I had a heck of a time getting it tangent with the rollers.

Later, Wes