The thing with ANY paper or fibre based gasket material, in the sizes and thicknesses we use on these models, it is very weak, plus it tends to get the sealing qualities destroyed once the joint is split, in other words, it is rather fragile.

With virgin PTFE, no other materials are required to get a good seal on the joint, oil, grease or jointing compound, it just seals for life. Once you have cut the gasket, basically, if you don't damage it on assembly or subsequent disassembly, it will last the lifetime of the model.

Having upgraded many engines to this gasket material sent to me for repair, I can honestly say, it is the best thing I have ever used, to the stage I wouldn't use anything else.

This is part of a gasket set I made for a Marcher engine sent to me for repair after the customer told me it had paper gasket failure on the steam chests. Due to the very high temperatures in the engine room and near to the boiler, the paper material and it's coating had failed and bits of it were drawn into the steam chest, consequently wearing grooves in the port faces.

Who says paper won't cause damage?

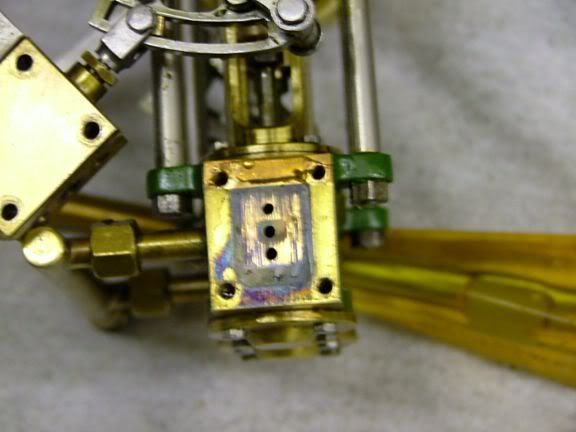

Port face on disassembly

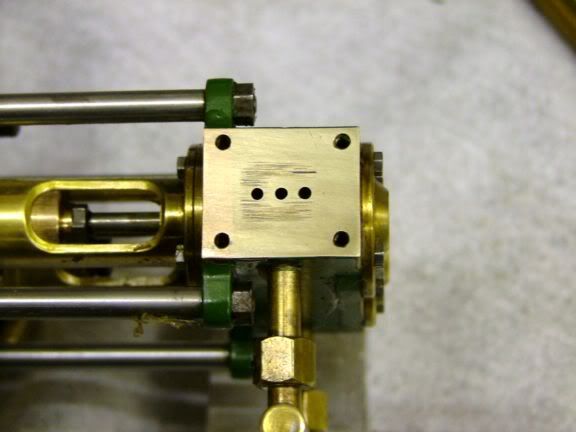

After it had basic cleaning, showing the scoring.

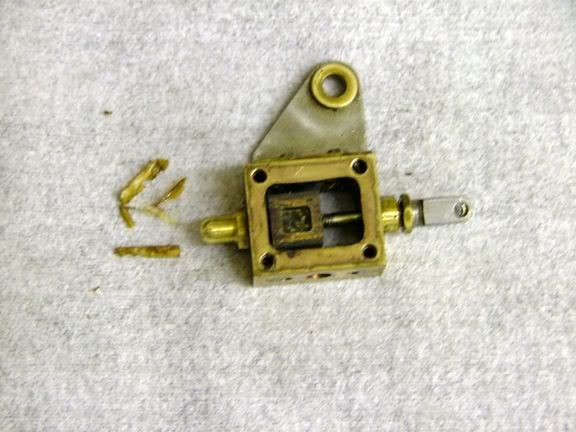

The culprit, the oil soaked paper had hardened and turned into like pieces of a razor blade. Once it got in around the slide valve, the seal was doomed to failure.

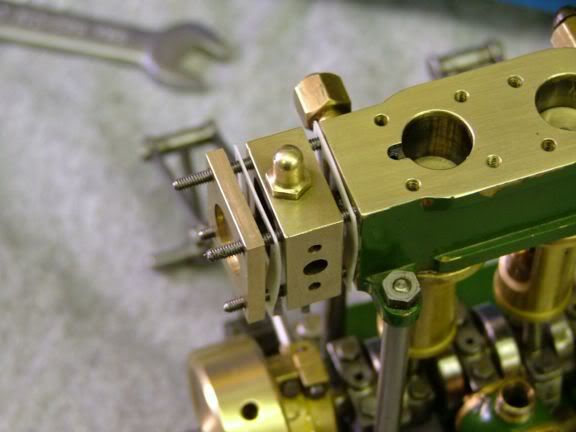

And the cure

Once every gasket on the engine was replaced with PTFE, and I had shown him where to put heat shielding around his boiler, it ran perfectly, and as far as I know, no further problems have ever arisen.

The problem is that people won't take on the qualities of new materials, and continue to use outdated methods for making gaskets that have been used for the last couple of hundred years. Ok, it is a bit more expensive, but to me, is easier to make gaskets from, just a craft knife, compass cutter and a set of hole punches and you should get gaskets that never blow, leak or cause damage, basically, cut, fit and forget.

John