Sorry its been a while since I've posted here but drop in often and check out the incredible work being done.

I keep busy in my machine shop and cabinet shop but seams all my metal work is in scale not suited.

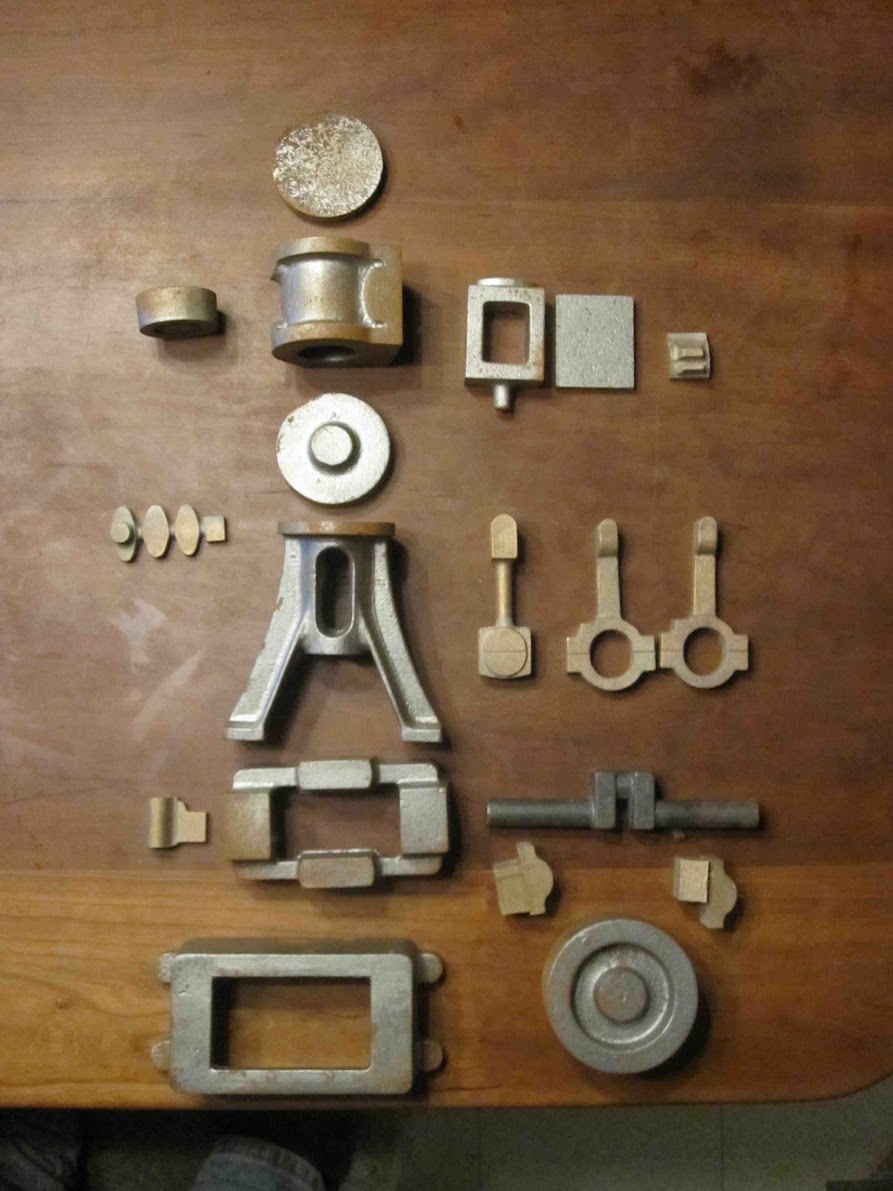

A couple of weeks ago I answered an ad for a metal bender on Kijiji, while picking it up I noticed a beautiful old wooden machinists chest. When I commented on it the chap said it had belonged to his father in laws dad, and he was upstairs. He and I got into a great conversation while going through the contents of the chest. He asked me if I'd be interested in a set of castings for a Stuart Engine. Seams he'd bought them years ago for his dad but he'd never got to them. So outside we go (with the bender), he goes to a large shed and comes back with a box. After looking them over I ask him how much he wanted for them. Well I'd like to see it completed and you look like someone who could do it, how does $50 sound. Any gun slinger would be proud how fast I drew my wallet.

This build may take some time as other projects will likely be pulling me away, but here goes.

The castings were incredible, never thought to ask how old they are.

The new kits come with all the bar stock, this one didn't, nor the rings, guess we'll be making them.

When it comes time to paint, Im lousy masking so I prefer painting before machining. Just so happens I'd just got into powder coating and thought this would be a good project to practise on. Sand blasted the castings and gave them a spray and bake.

Like the finish powder coating gives, though it may appear a little thick for models. I think this engine being on the larger size can pull it off.

Thanks for looking.

Greg

I keep busy in my machine shop and cabinet shop but seams all my metal work is in scale not suited.

A couple of weeks ago I answered an ad for a metal bender on Kijiji, while picking it up I noticed a beautiful old wooden machinists chest. When I commented on it the chap said it had belonged to his father in laws dad, and he was upstairs. He and I got into a great conversation while going through the contents of the chest. He asked me if I'd be interested in a set of castings for a Stuart Engine. Seams he'd bought them years ago for his dad but he'd never got to them. So outside we go (with the bender), he goes to a large shed and comes back with a box. After looking them over I ask him how much he wanted for them. Well I'd like to see it completed and you look like someone who could do it, how does $50 sound. Any gun slinger would be proud how fast I drew my wallet.

This build may take some time as other projects will likely be pulling me away, but here goes.

The castings were incredible, never thought to ask how old they are.

The new kits come with all the bar stock, this one didn't, nor the rings, guess we'll be making them.

When it comes time to paint, Im lousy masking so I prefer painting before machining. Just so happens I'd just got into powder coating and thought this would be a good project to practise on. Sand blasted the castings and gave them a spray and bake.

Like the finish powder coating gives, though it may appear a little thick for models. I think this engine being on the larger size can pull it off.

Thanks for looking.

Greg