You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

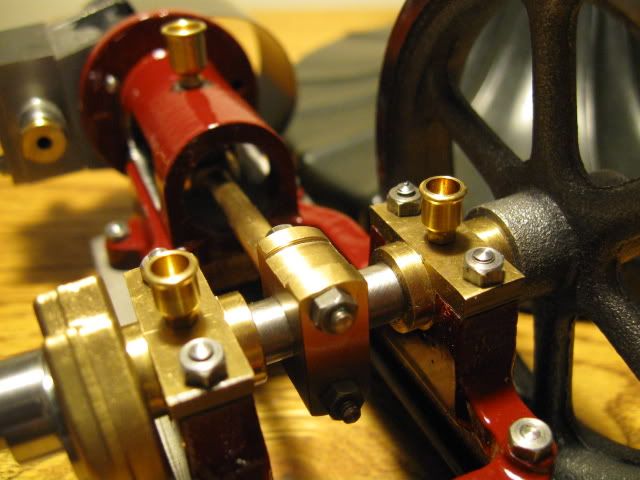

Stuart 10H

- Thread starter Jeff02

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Tin Falcon

Well-Known Member

- Joined

- Jul 9, 2007

- Messages

- 7,207

- Reaction score

- 787

Jeff did you invest in BA taps or did you change hardware size to US Sizes?

Tin

Tin

Jeff02

Well-Known Member

- Joined

- Aug 12, 2008

- Messages

- 195

- Reaction score

- 2

I have been using 600 grit wet and dry sand paper with a lot of elbow grease and water.

I guess I should say I start with a file, then go to sand paper starting with 300 grit and working up to 600.

BTW I have just used the 300, I save the 600 until the very last.

I guess I should say I start with a file, then go to sand paper starting with 300 grit and working up to 600.

BTW I have just used the 300, I save the 600 until the very last.

kellswaterri

Senior Member

- Joined

- Oct 14, 2007

- Messages

- 117

- Reaction score

- 6

Hi Jeff, nicely done with the engine build...did you encounter any problems fitting the nuts to hold the Cylinder to the body of the engine... two things, one size Smaller nuts are available in most BA sizes...also I personally think the drawing pitch circle for the studs holding Cyl/ to engine body is a tad too small...I found this out the hard way on the Score build :

All the best for now,

John.

All the best for now,

John.

Jeff02

Well-Known Member

- Joined

- Aug 12, 2008

- Messages

- 195

- Reaction score

- 2

Bob and John, Thanks for the kind words.

Yes I to think Diameter is too small, this is my third and on my other two I said the same thing, I think on my forth I will increase by about an 1/8 of an inch on the total diameter this will give me 1/16 a side.

Yes I to think Diameter is too small, this is my third and on my other two I said the same thing, I think on my forth I will increase by about an 1/8 of an inch on the total diameter this will give me 1/16 a side.

tel

Well-Known Member

- Joined

- Feb 8, 2008

- Messages

- 3,293

- Reaction score

- 44

Jeff02 said:I have been using 600 grit wet and dry sand paper with a lot of elbow grease and water.

I guess I should say I start with a file, then go to sand paper starting with 300 grit and working up to 600.

BTW I have just used the 300, I save the 600 until the very last.

Try some light oil with the w&d - makes a difference!

Jeff02 said:

That's a neat little oil cup. Did you use a form tool to shape it?

If you did, would you mind giving us all a blow-by-blow account of how you made the tool.

Thanks,

Dave

The Emerald Isle

Jeff02

Well-Known Member

- Joined

- Aug 12, 2008

- Messages

- 195

- Reaction score

- 2

Sorry, but the oil cups are from PM Research. There is how ever an article in Issue 18 of Model Engine Builder on how to make them.

http://www.pmresearchinc.com/store/home.php?cat=23

http://www.pmresearchinc.com/store/home.php?cat=23

dparker

In Rembrance 8/2021

- Joined

- Aug 24, 2007

- Messages

- 218

- Reaction score

- 5

Jeff02:

That looks so nice it makes me want to build that model also, except being on disability and married now the kit prices tend to scare me towards bar stock type plans . Many years ago I built the 10V and it is a real good runner and catches everybody's attention when they see it running in my basement shop. I thought when I built it I wanted to run it on steam but the thought of building a safe boiler back in the 1970's scared me enough that I just run it with my air compressor.

Good work-------don

That looks so nice it makes me want to build that model also, except being on disability and married now the kit prices tend to scare me towards bar stock type plans . Many years ago I built the 10V and it is a real good runner and catches everybody's attention when they see it running in my basement shop. I thought when I built it I wanted to run it on steam but the thought of building a safe boiler back in the 1970's scared me enough that I just run it with my air compressor.

Good work-------don

- Joined

- Aug 8, 2009

- Messages

- 930

- Reaction score

- 12

Very nice, Jeff.

I've been trying to think of a way to make engines look like they were cast but without actually casting them. Haven't gotten there yet. ;D

I plan on doing some rounded edges, which will help a little.

-Trout

I've been trying to think of a way to make engines look like they were cast but without actually casting them. Haven't gotten there yet. ;D

I plan on doing some rounded edges, which will help a little.

-Trout

Similar threads

- Replies

- 4

- Views

- 564

- Replies

- 3

- Views

- 561

- Replies

- 1

- Views

- 409