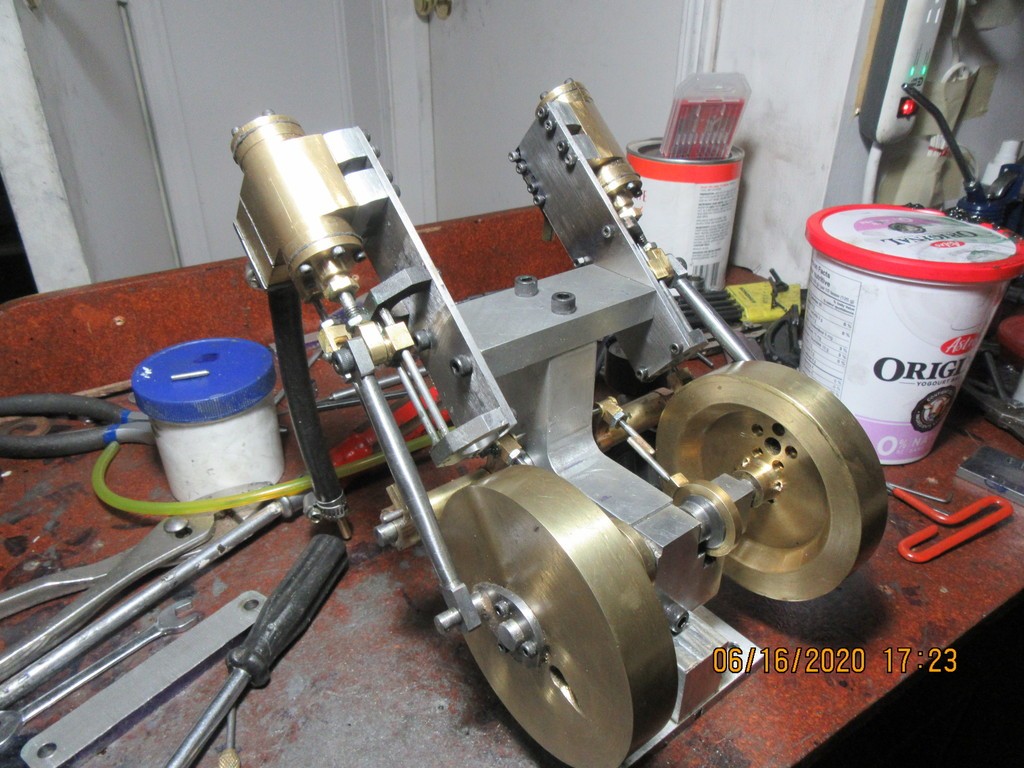

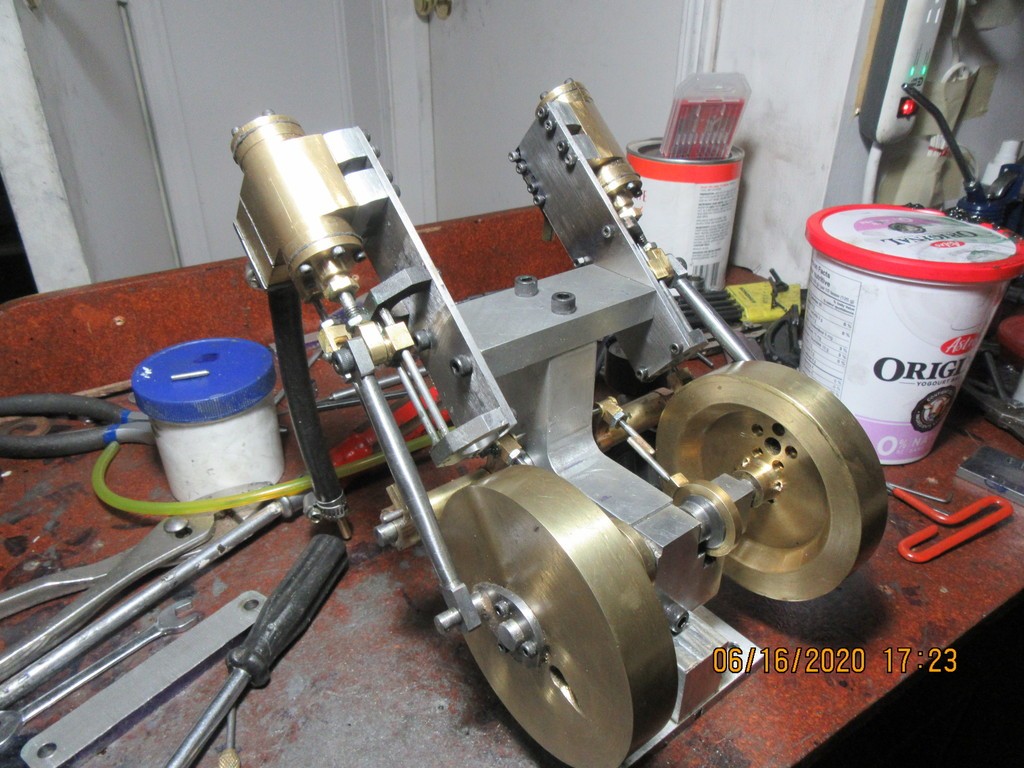

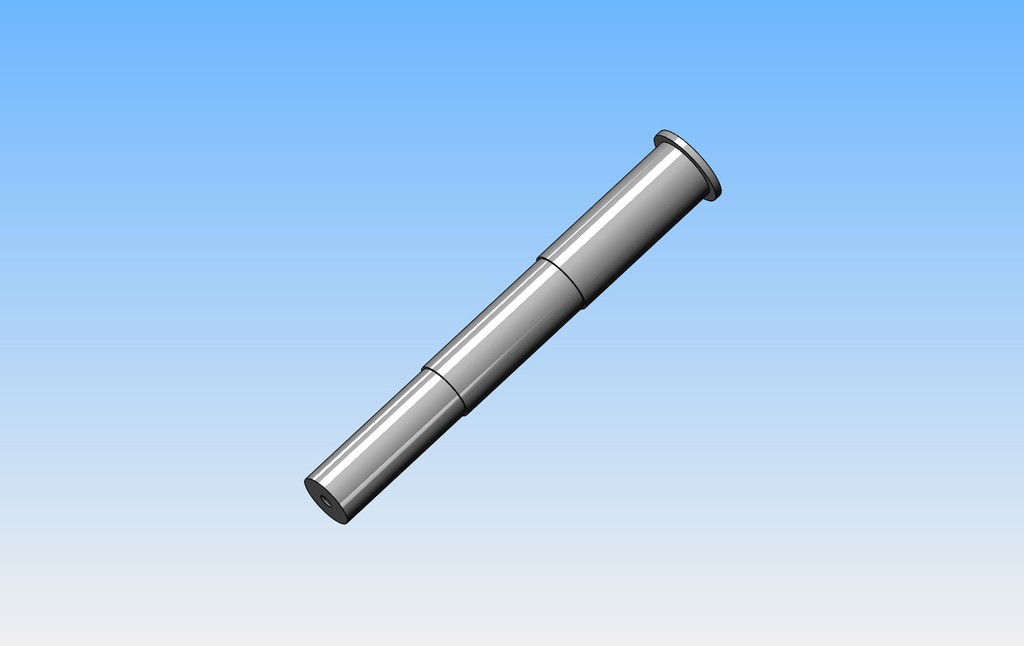

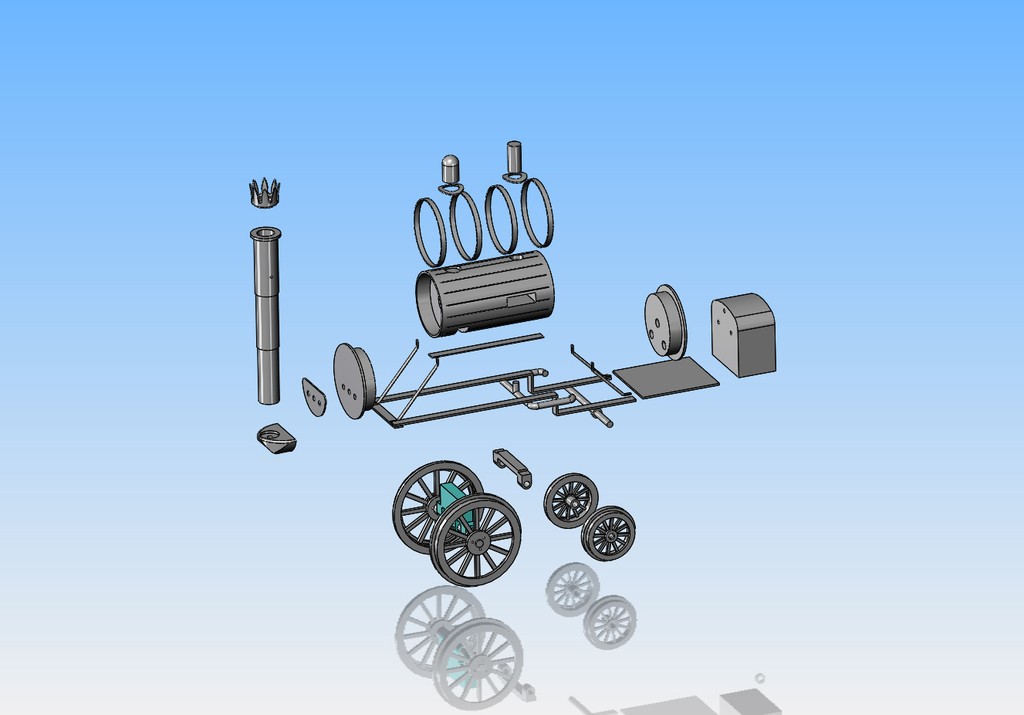

So now my engine(s) have two of the fanciest connecting rods that I've ever made. They turned out very nice, although there seemed to be a ton of work in them. The con rods were the last two pieces needed to make my engine set-up run. Now I have to spend time working out all the "stiffness" so I can get things to run on about 15 to 20 psi of air.