Hi Folks,

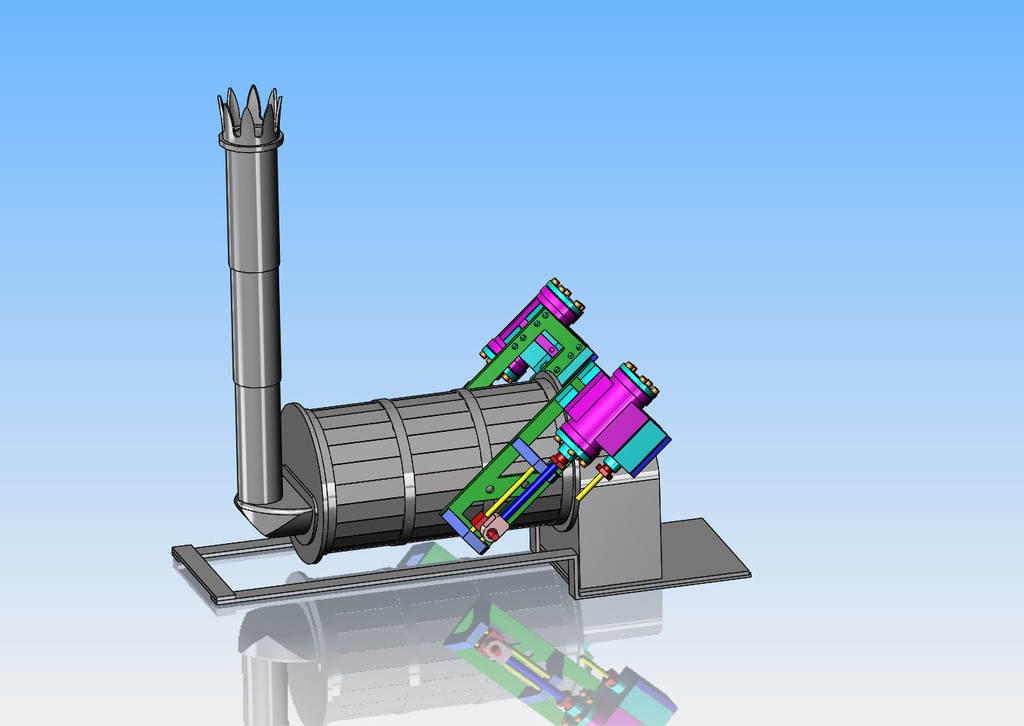

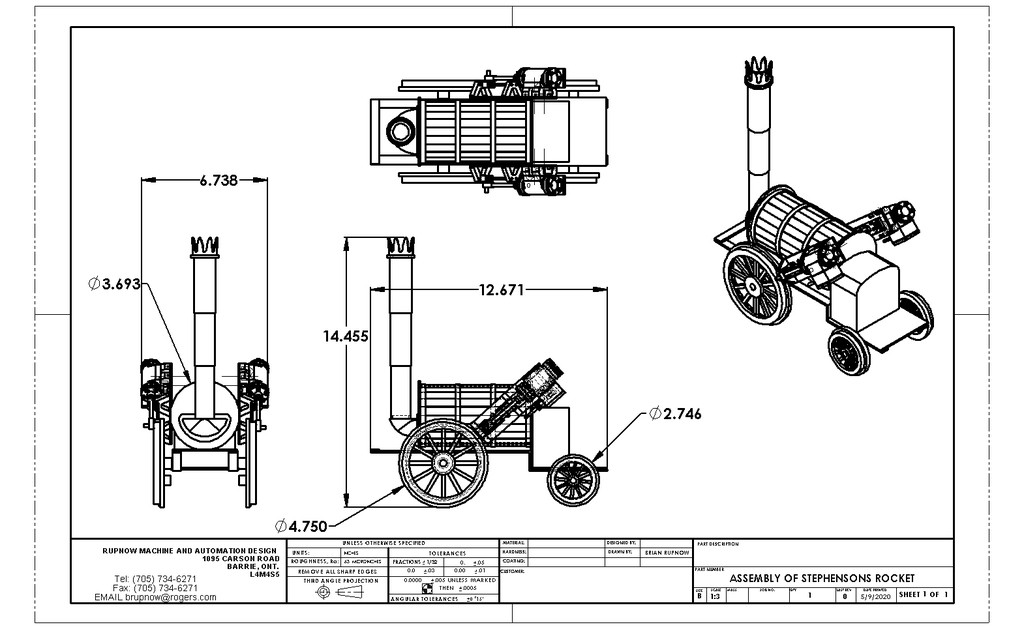

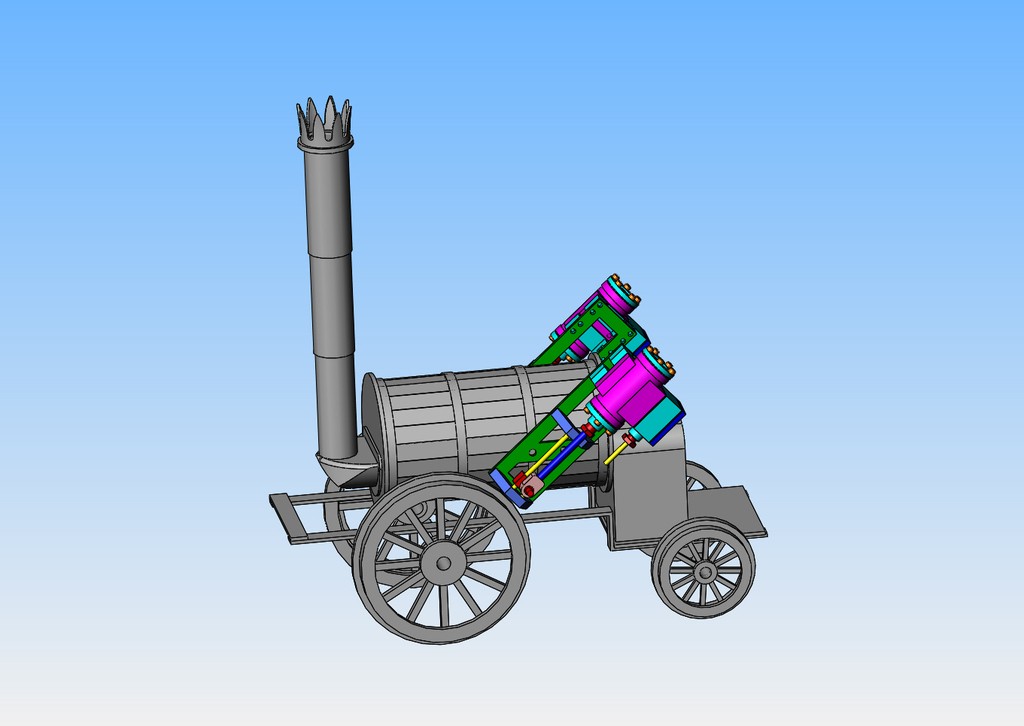

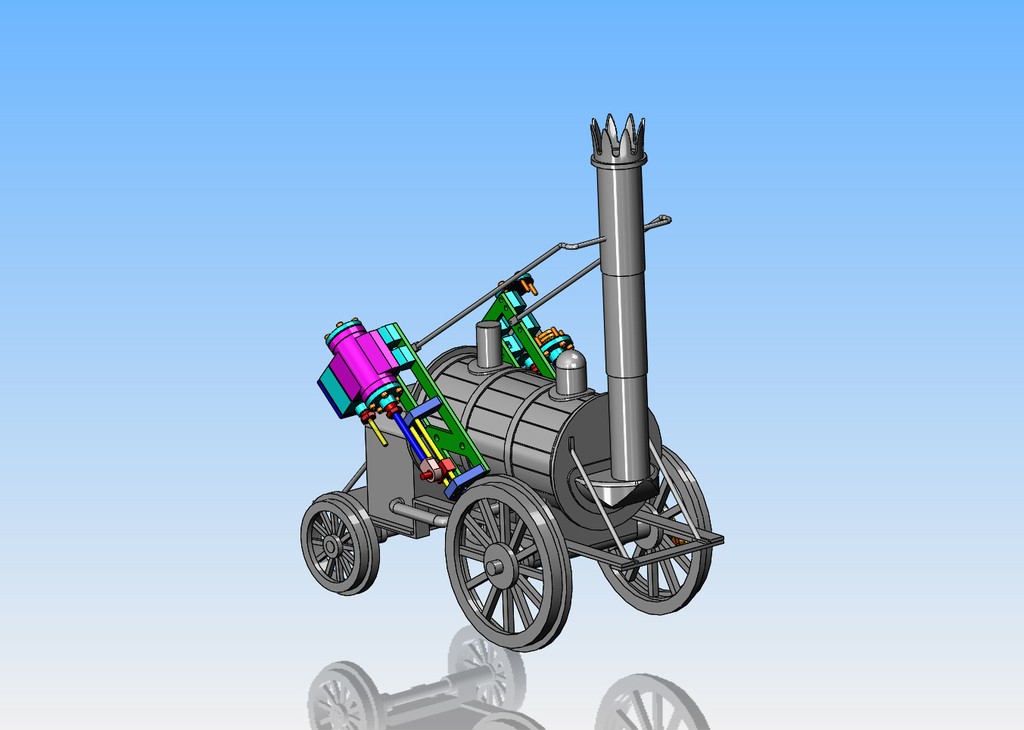

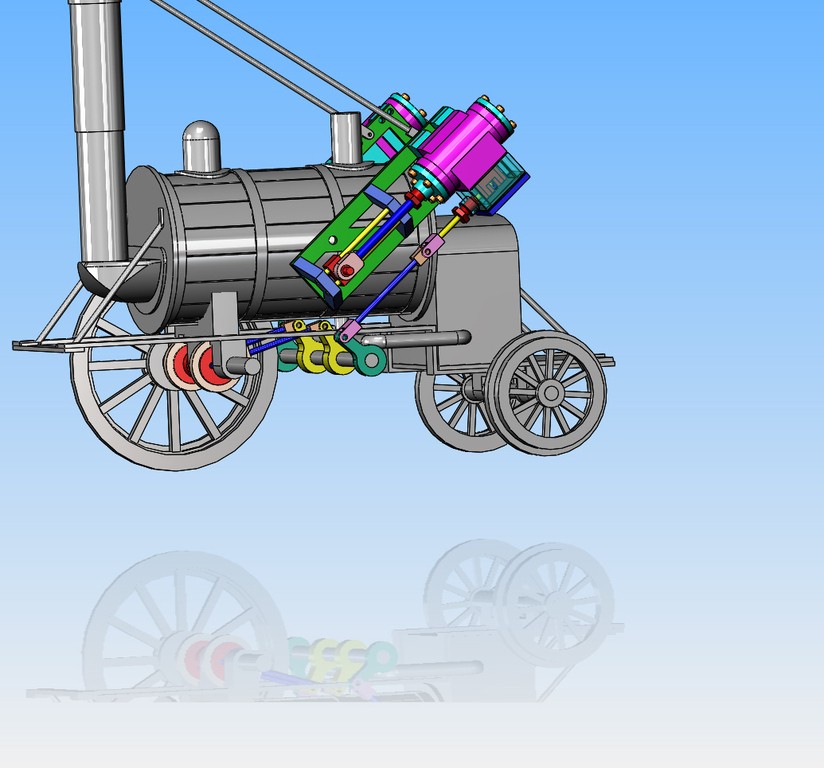

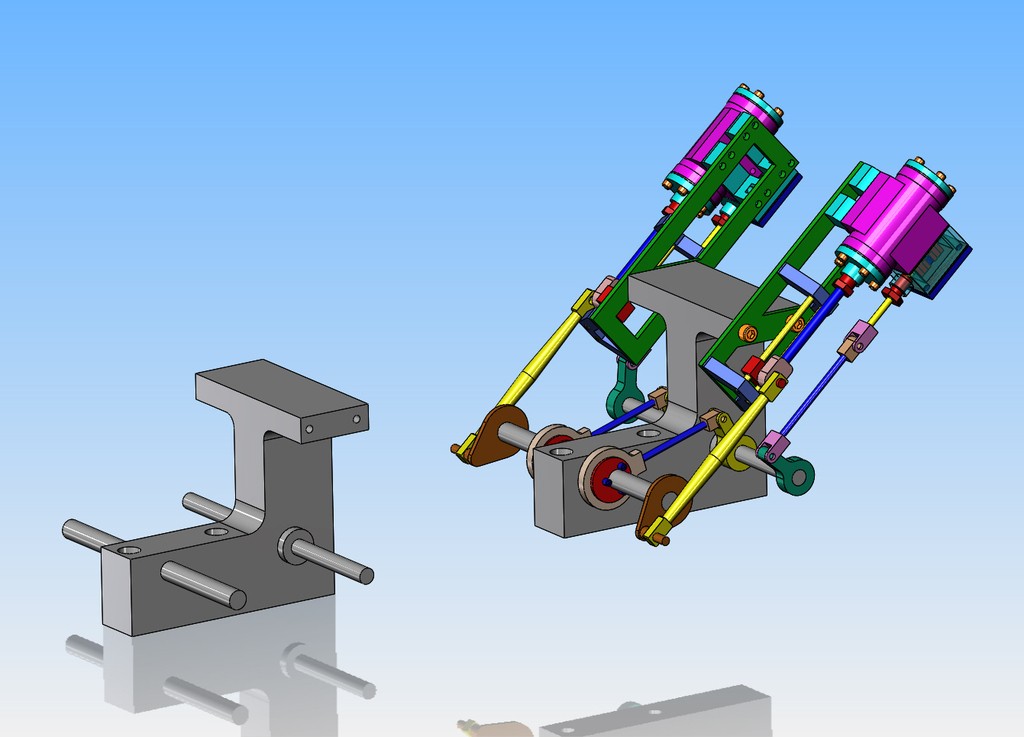

Over the years I've noticed the angle of the cylinders appears to be at about 30 degrees to horizontal. The cylinders are quite a bit lower in angle on the original as shown at the Science Museum in London.

https://collection.sciencemuseumgroup.org.uk/objects/co8084947/stephensons-rocket-steam-locomotive

It's a neat model either way, but I was wondering if the folks who put the pieces of the original together just got it wrong, or if all the replicas thereafter have it "wrong". Could be Rev 1.1 of the engine increased the angle and all the versions built after the competition used the higher angle. I've never found a definitive answer, probably looking in the wrong places. Anyone know?

Over the years I've noticed the angle of the cylinders appears to be at about 30 degrees to horizontal. The cylinders are quite a bit lower in angle on the original as shown at the Science Museum in London.

https://collection.sciencemuseumgroup.org.uk/objects/co8084947/stephensons-rocket-steam-locomotive

It's a neat model either way, but I was wondering if the folks who put the pieces of the original together just got it wrong, or if all the replicas thereafter have it "wrong". Could be Rev 1.1 of the engine increased the angle and all the versions built after the competition used the higher angle. I've never found a definitive answer, probably looking in the wrong places. Anyone know?