Hi All

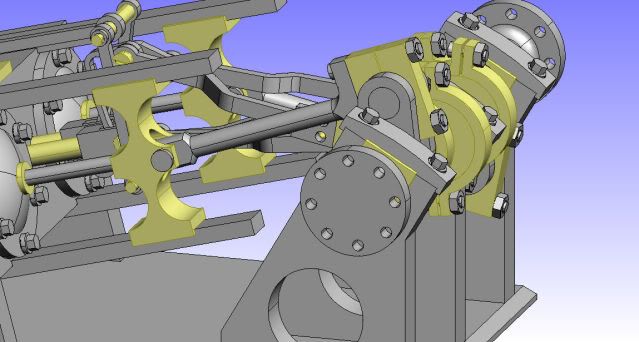

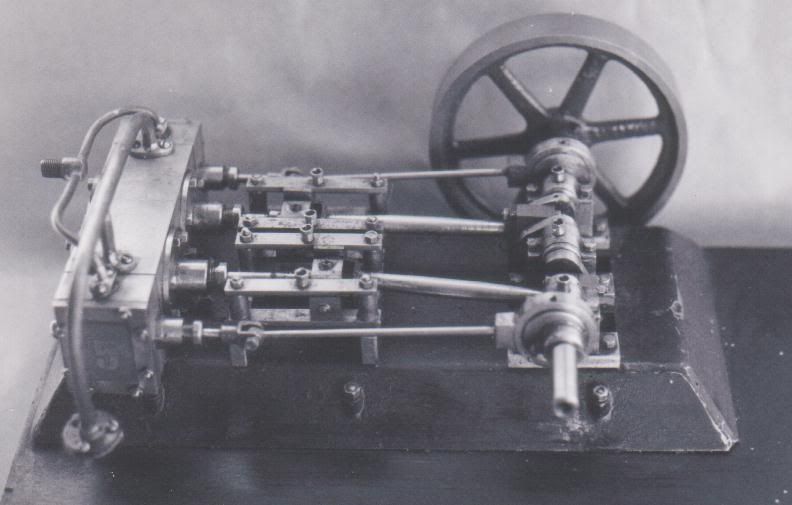

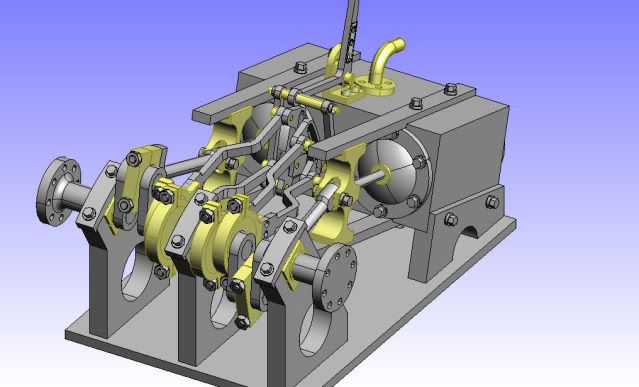

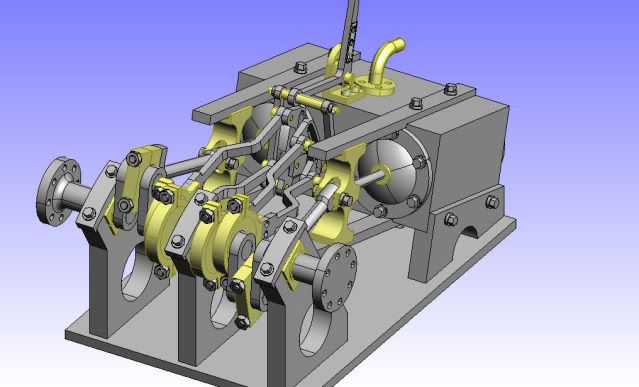

Now my next project is finished in the virtual world, now I have to go to the shop and see if I can make the pile of material tranform into something that will look like the digital form.

Any comment is welcome before I start cutting metal

Mogens

Now my next project is finished in the virtual world, now I have to go to the shop and see if I can make the pile of material tranform into something that will look like the digital form.

Any comment is welcome before I start cutting metal

Mogens