Well, maybe I should elaborate a bit more, after my "intervention"/bump in the other thread: http://www.homemodelenginemachinist.com/f26/steam-vacuum-engine-anyone-built-one-19538/#post217342

What I am planning to do, is to build a "steam-to-vacuum" engine, with a working cycle that is similar to that of the well known "flame eater".

One would ask: Why?

Because I think that a design like that, could have some serious advantages over both the conventional steam engine, and the conventional flame eater.

On top of that, I'm planning to "designbuild" (so there will be no real "plans") an engine that can be built from hardware store materials, and/or waste materials, in order to enable "people on a budget" and with few sophisticated tools, to share in the fun of engineering.

In theory (all is theory, since i haven't built anything yet), I see the following operational advantages over "conventional" flame- and steam engines.

1. The boiler is unpressurized, so there is no danger of explosions, or the need to meet up with safety regulations whatsoever.

2. The operating temperature of the cylinder, is below 100 celsius, so even plasstcs could be used for piston(s) and/or cylinder(s).

(like PVC and epoxy)

3. A vacuum caused by steam, is "deeper" than a vacuum caused by air, and therefore probably more able to produce a considerable powerstroke. Compared to the conventional flame licker, that is. You might actually be able to drive something with it.

A Disadvantage could be:

1. While I think the stronger vacuüm, caused by condensing steam, might make the "steam eater" stronger than a conventional flame eater: I don't think it could ever beat a conventional steam engine in terms of power and efficiency.

A few real "Don't know"s are:

1. Would steam condense fast enough, to make the cycle work?

2. Would the process of forcing condense out of the cylinder cause too much resistance to keep the engine running?

So I'm yet to discover at least about these two last points.

Any advice would be welcome.

So, over now to the working cycle.

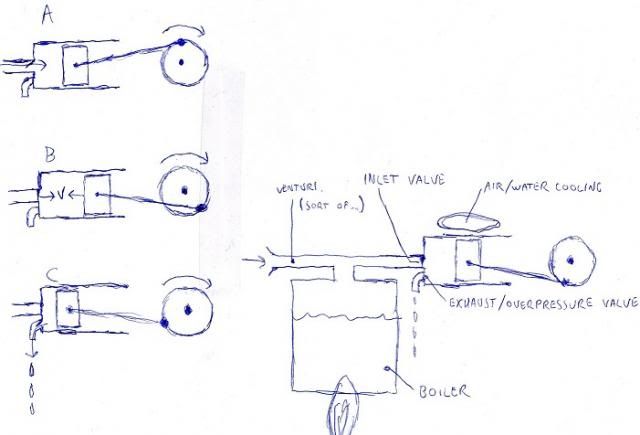

I'm not much of a computer type of person, so a few badly drawn schematics must do the job for now.

The theory is:

In figure A, the intake valve is open.

The piston is in its downstroke, sucking in steam, and maybe a little preheated air into the cylinder.

In figure B, the intake valve just closed at BDC, and the steam "collapses" into condense, creating a powerfull vacuüm, which draws the piston "upwards'.

In figure C, the piston approaches TDC, and the "exhaust" opens due to overpressure in the cylinder. The remaining steam and/or water are driven out of the cylinder. (back to A)

I could not get the drawing to properly scan as a whole, so I just cut the drawing in two pieces, taping them together. Off to a flimsy start!

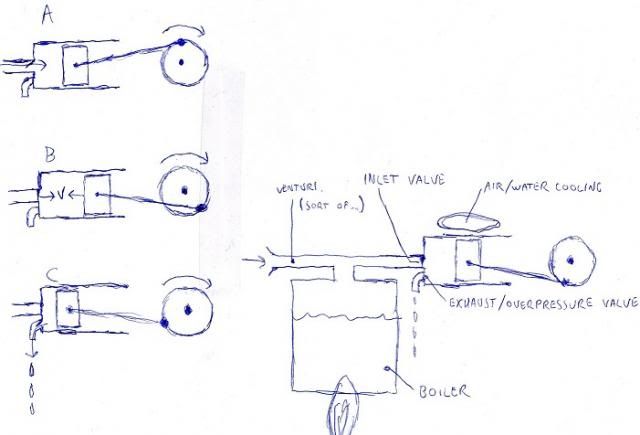

In the larger picture on the right, is a schematic of the whole contraption.

The 'venturi" of the "carburettor-boiler" allows for air to be sucked in, in case of lagging steam production, while it allows a free "blow-off" as well, in case the engine can't keep up with the steam production.

I hope I hereby was able to create a better understanding of my plans.

And everything is out in the open.

If anyone feels the need to start with this project before I do: Just go ahead. If you want to share the schematics: Go ahead.

I'm a strong believer in open-source-everything.

Imagine the wheel still beïng the intellectual property of someone else..

What I am planning to do, is to build a "steam-to-vacuum" engine, with a working cycle that is similar to that of the well known "flame eater".

One would ask: Why?

Because I think that a design like that, could have some serious advantages over both the conventional steam engine, and the conventional flame eater.

On top of that, I'm planning to "designbuild" (so there will be no real "plans") an engine that can be built from hardware store materials, and/or waste materials, in order to enable "people on a budget" and with few sophisticated tools, to share in the fun of engineering.

In theory (all is theory, since i haven't built anything yet), I see the following operational advantages over "conventional" flame- and steam engines.

1. The boiler is unpressurized, so there is no danger of explosions, or the need to meet up with safety regulations whatsoever.

2. The operating temperature of the cylinder, is below 100 celsius, so even plasstcs could be used for piston(s) and/or cylinder(s).

(like PVC and epoxy)

3. A vacuum caused by steam, is "deeper" than a vacuum caused by air, and therefore probably more able to produce a considerable powerstroke. Compared to the conventional flame licker, that is. You might actually be able to drive something with it.

A Disadvantage could be:

1. While I think the stronger vacuüm, caused by condensing steam, might make the "steam eater" stronger than a conventional flame eater: I don't think it could ever beat a conventional steam engine in terms of power and efficiency.

A few real "Don't know"s are:

1. Would steam condense fast enough, to make the cycle work?

2. Would the process of forcing condense out of the cylinder cause too much resistance to keep the engine running?

So I'm yet to discover at least about these two last points.

Any advice would be welcome.

So, over now to the working cycle.

I'm not much of a computer type of person, so a few badly drawn schematics must do the job for now.

The theory is:

In figure A, the intake valve is open.

The piston is in its downstroke, sucking in steam, and maybe a little preheated air into the cylinder.

In figure B, the intake valve just closed at BDC, and the steam "collapses" into condense, creating a powerfull vacuüm, which draws the piston "upwards'.

In figure C, the piston approaches TDC, and the "exhaust" opens due to overpressure in the cylinder. The remaining steam and/or water are driven out of the cylinder. (back to A)

I could not get the drawing to properly scan as a whole, so I just cut the drawing in two pieces, taping them together. Off to a flimsy start!

In the larger picture on the right, is a schematic of the whole contraption.

The 'venturi" of the "carburettor-boiler" allows for air to be sucked in, in case of lagging steam production, while it allows a free "blow-off" as well, in case the engine can't keep up with the steam production.

I hope I hereby was able to create a better understanding of my plans.

And everything is out in the open.

If anyone feels the need to start with this project before I do: Just go ahead. If you want to share the schematics: Go ahead.

I'm a strong believer in open-source-everything.

Imagine the wheel still beïng the intellectual property of someone else..

Last edited by a moderator: