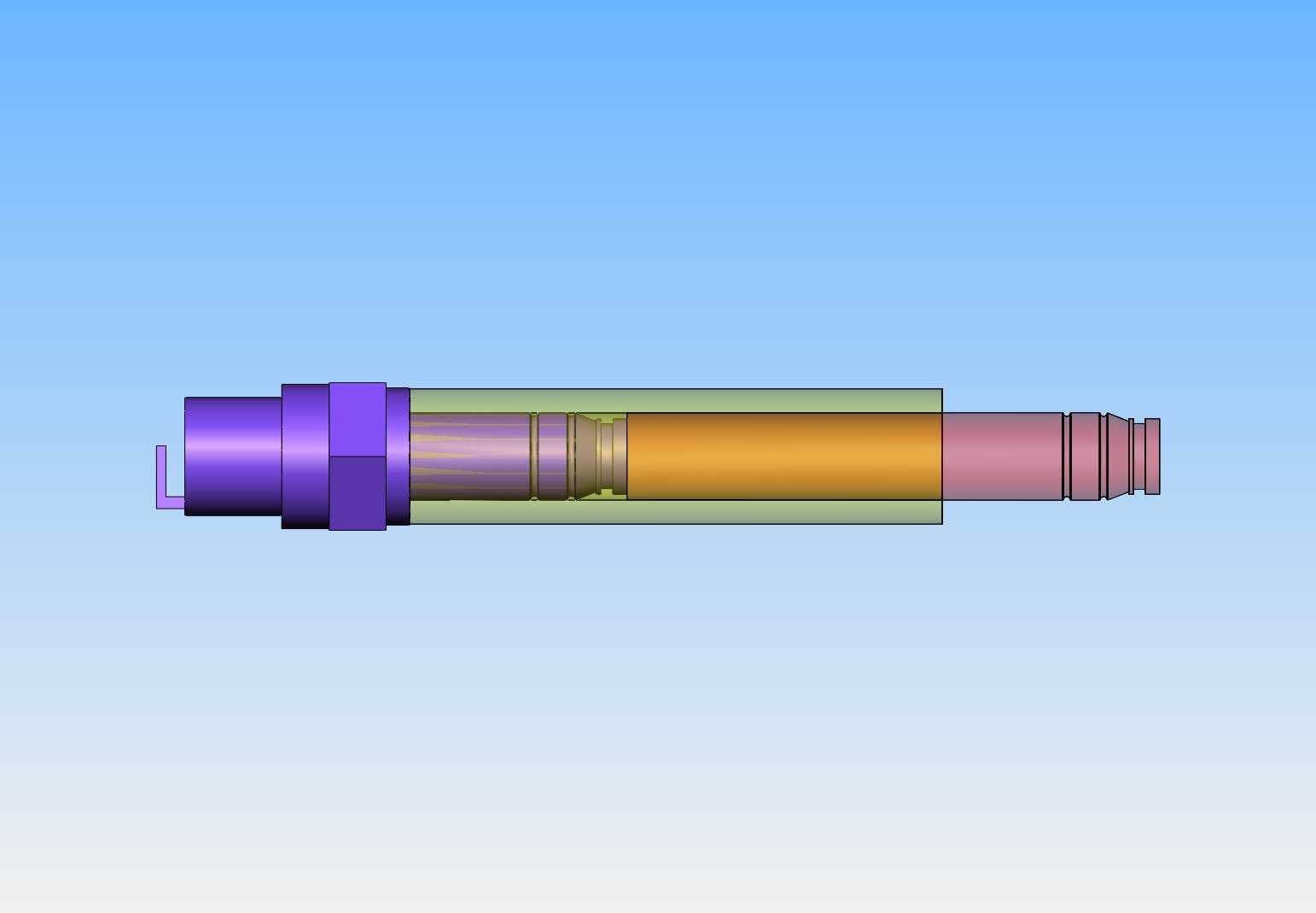

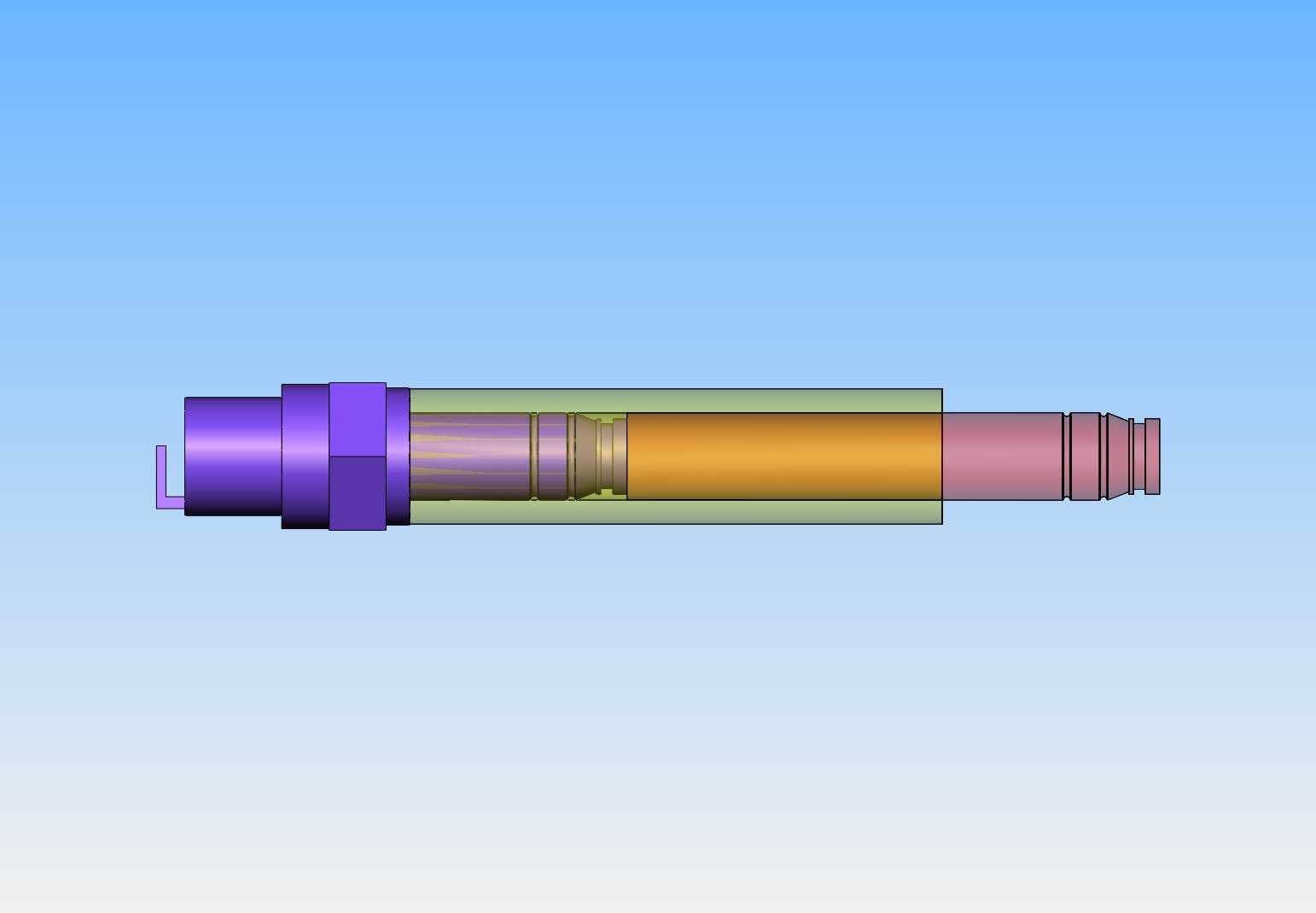

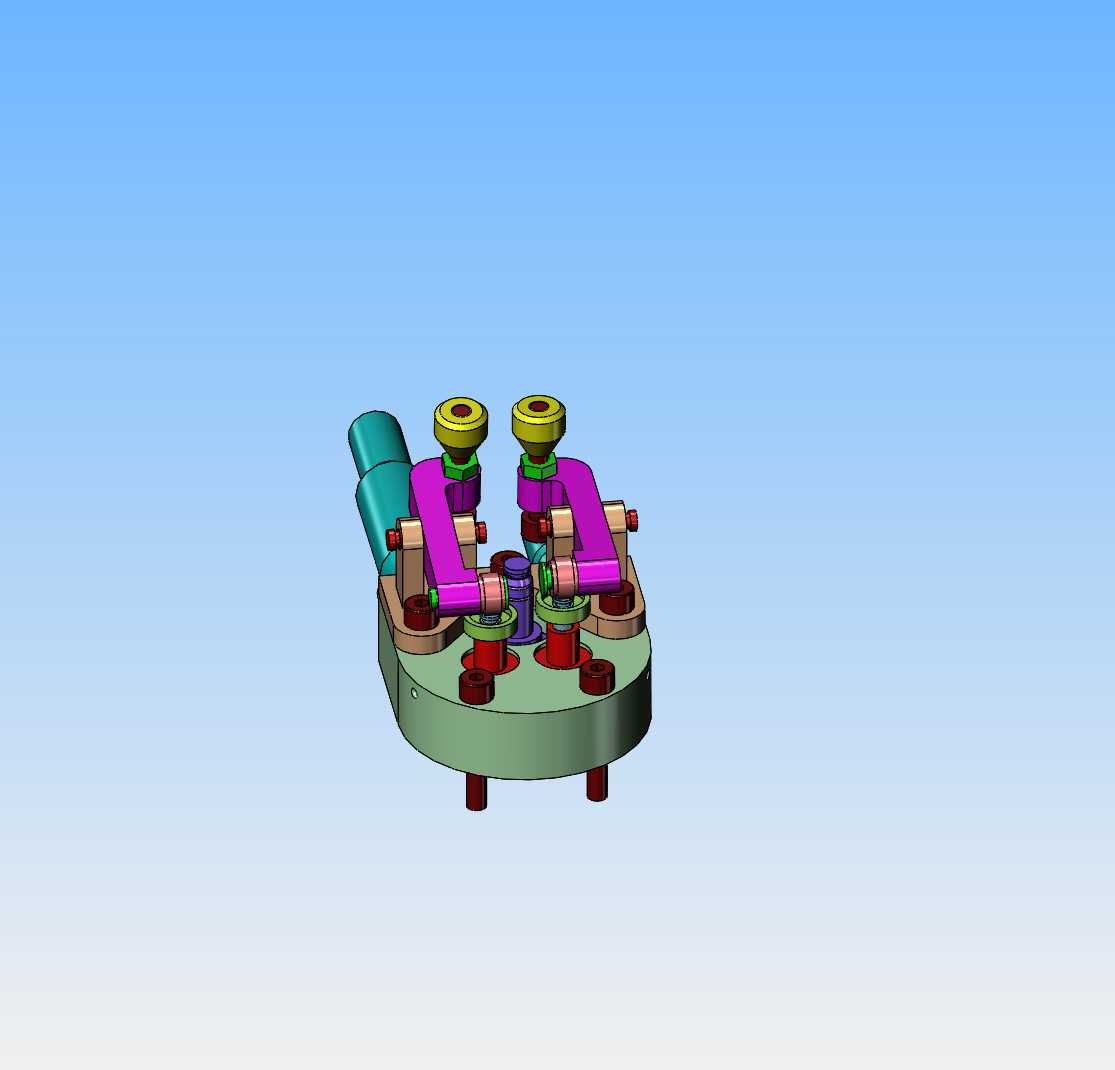

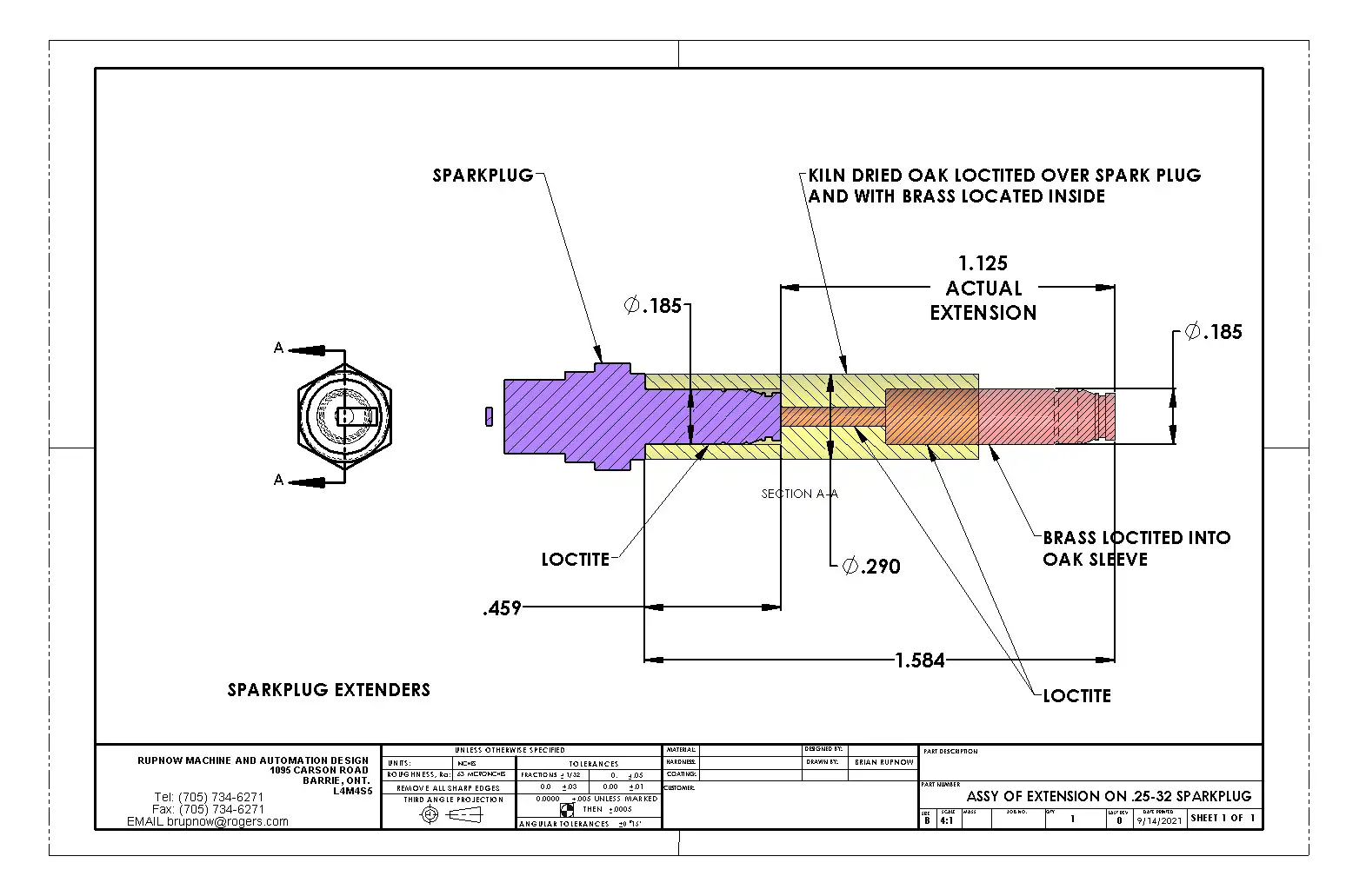

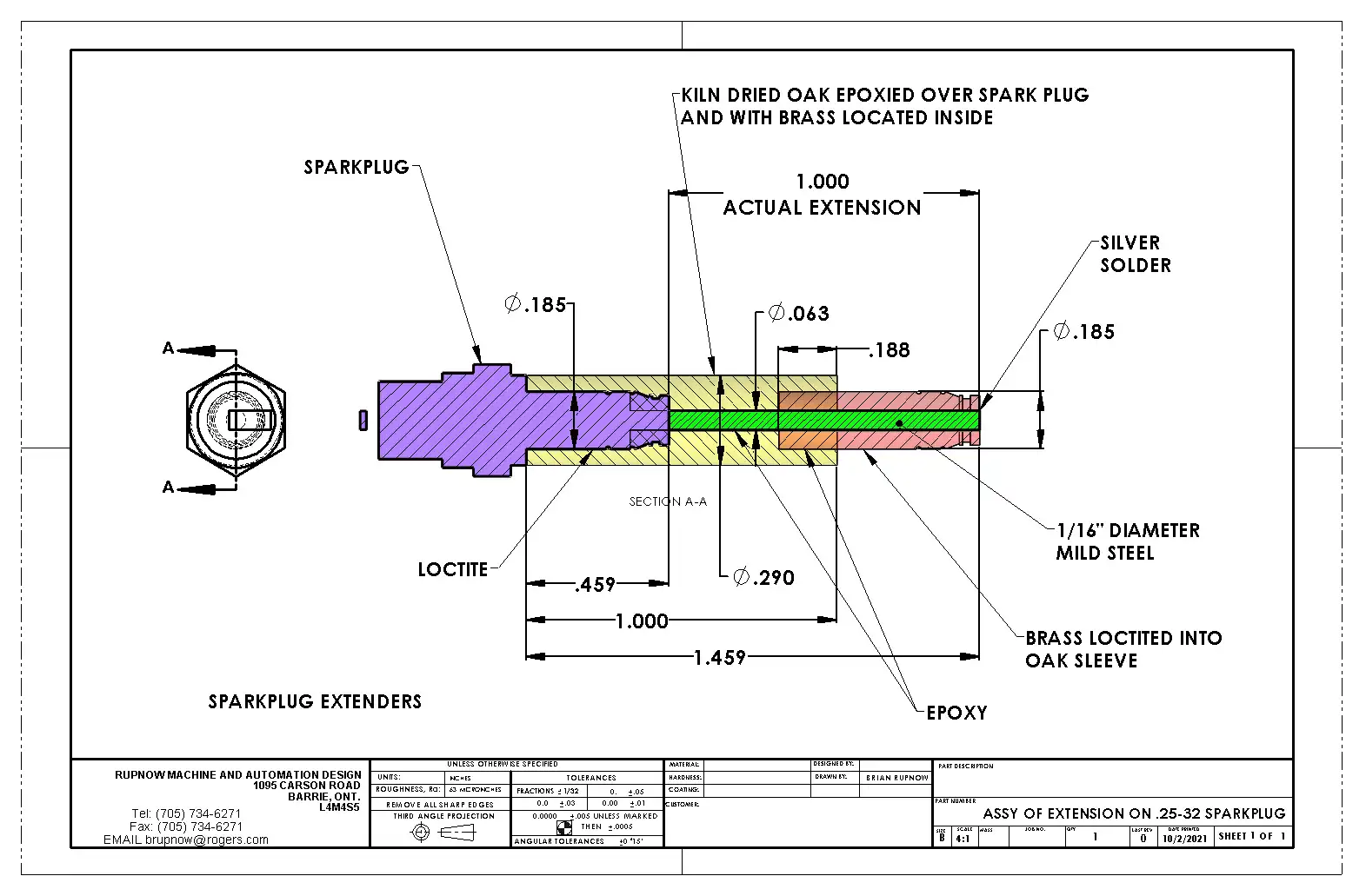

Has anyone ever seen or know of a sparkplug extension that looks like the one in this picture? The plug is a Rimfire .25-32. I want to nest this plug down between two rocker arms and not have the spark shorting out and snapping to the rocker arms instead of to the end of the sparkplug. The red and yellow parts I show is the extension. The purple is the original rimfire sparkplug. The red part would have to be steel or brass. The yellow part would be something non-conductive that was resilient like rubber so it would "grip" the end of the sparkplug. Strange question, I know, but I have a reason to ask.---Brian