Hi All,

My workshop is an extended garage divided into four 'rooms'. One is for the freezer and household junk. Next is my computer room. The next is my workshop with a machine shop beyond.

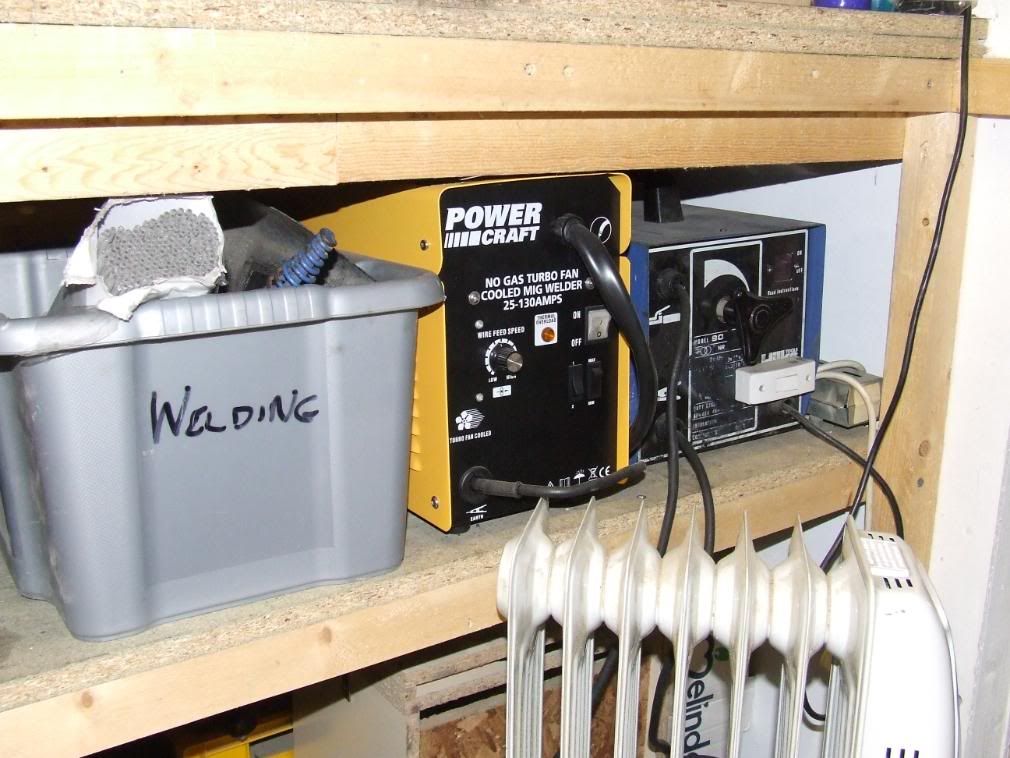

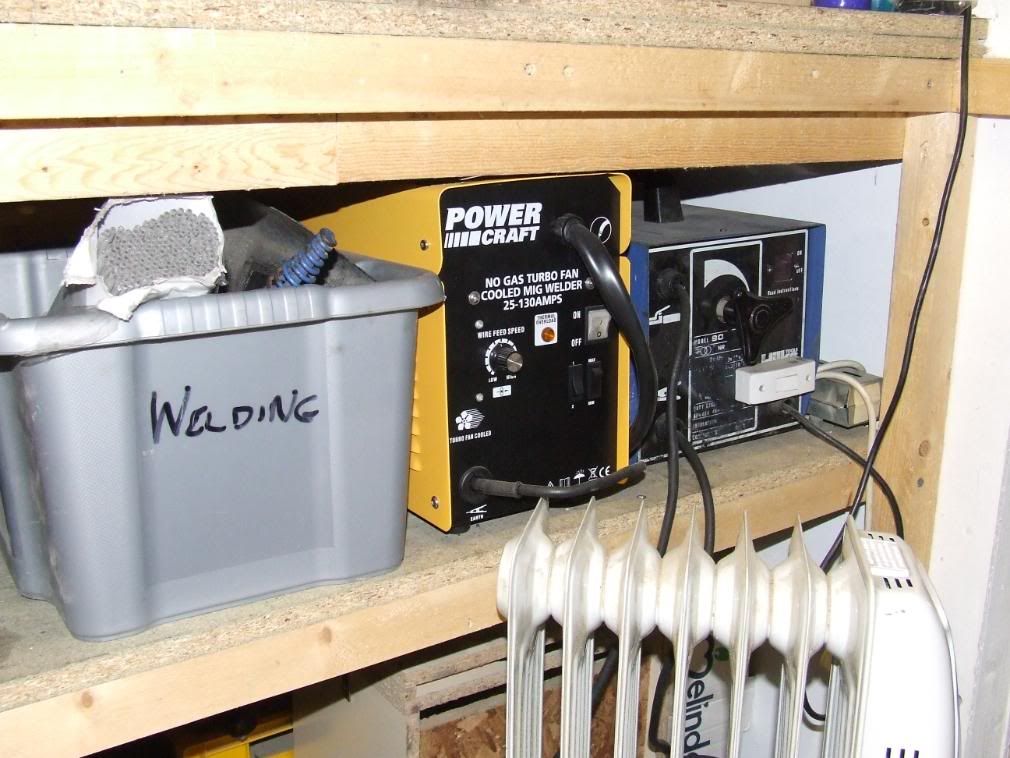

The bench to the right is 3.5m long and almost a metre deep. My lathe was in here but I decided to build the machine shop. All that is in here now are the welders both mig and arc. a cheap drill press and a Warco sander.

My machine shop has a Seig Mill soon to be partially cnc'd if I get the time and inclination to build it.

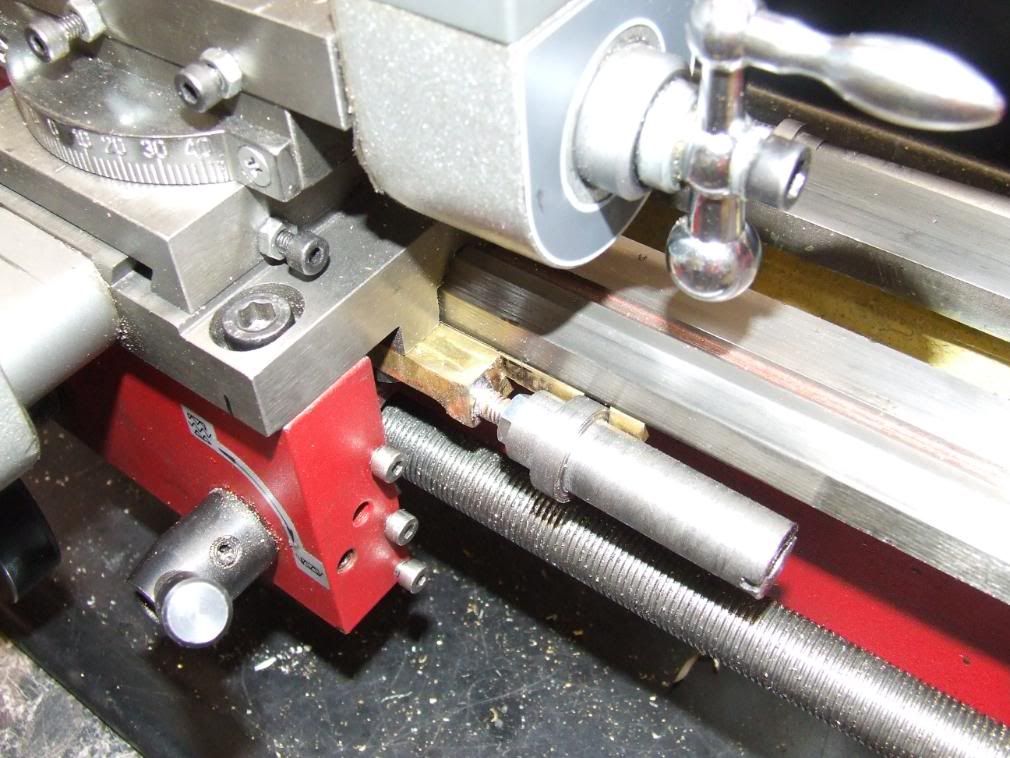

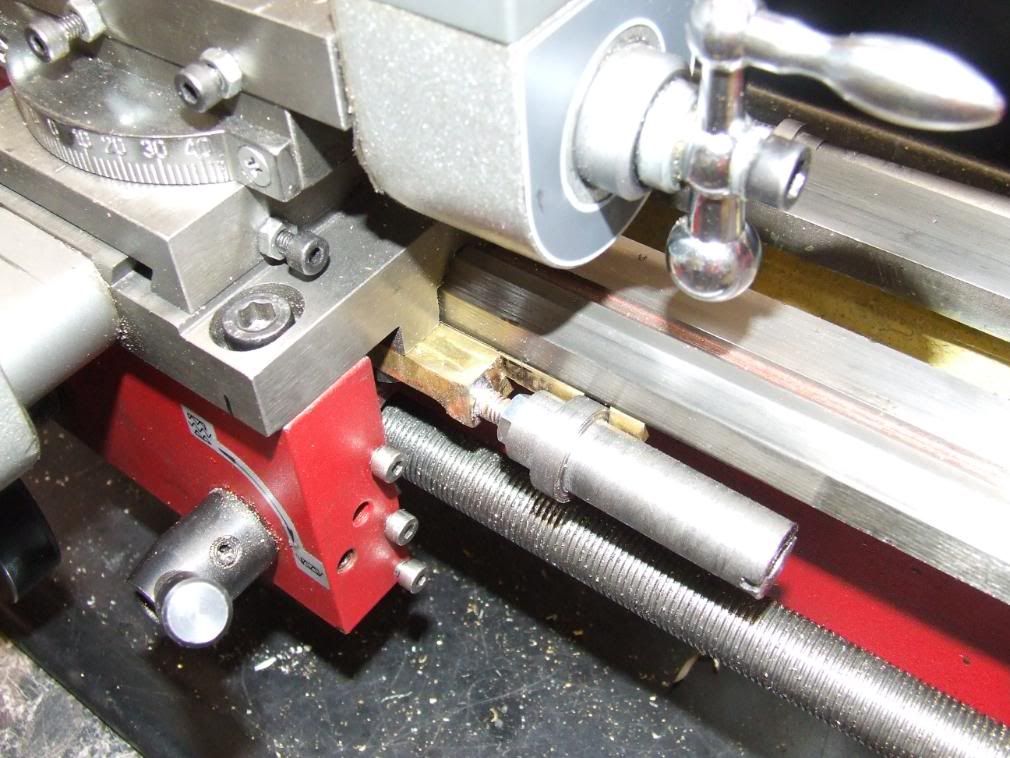

A seig lathe with a mod to the crossfeed to bed sliders...very necessary.

And finally 'The Beast' . This is my latest acquisition a forty year old Denford Viceroy Lathe. Nothing stops the beast which weighs in at over 300kg.

Lots of space and plenty of storage. As you can see I am a very messy worker but hey why tidy up....you never can find anything until it is messy again!

Julian

My workshop is an extended garage divided into four 'rooms'. One is for the freezer and household junk. Next is my computer room. The next is my workshop with a machine shop beyond.

The bench to the right is 3.5m long and almost a metre deep. My lathe was in here but I decided to build the machine shop. All that is in here now are the welders both mig and arc. a cheap drill press and a Warco sander.

My machine shop has a Seig Mill soon to be partially cnc'd if I get the time and inclination to build it.

A seig lathe with a mod to the crossfeed to bed sliders...very necessary.

And finally 'The Beast' . This is my latest acquisition a forty year old Denford Viceroy Lathe. Nothing stops the beast which weighs in at over 300kg.

Lots of space and plenty of storage. As you can see I am a very messy worker but hey why tidy up....you never can find anything until it is messy again!

Julian