David Morrow

Well-Known Member

- Joined

- Sep 8, 2008

- Messages

- 227

- Reaction score

- 60

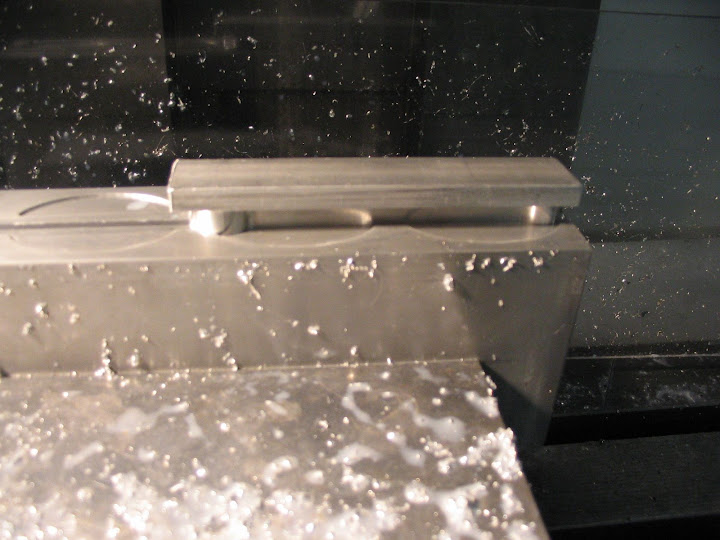

I probably wouldn't even be making engines if I didn't have a little CNC mill. And this is one job that definitely wouldn't be possible without it. This is a connecting rod for my Coss Horizontal Stirling - still in progress. The end mill in the photo is .020". I normally cut a .004" deep per pass at about .5" / minute. It may be able to go a bit faster & deeper but the whole job is only 8 minutes per pass so there's no need to rush. Total depth of the lettering is .010"

This is the project in full, or at least as far as last night's progress :

http://www.ldrider.ca/cnc/coss-horizontal/coss-horizontal.htm

This is the project in full, or at least as far as last night's progress :

http://www.ldrider.ca/cnc/coss-horizontal/coss-horizontal.htm