- Joined

- Jun 24, 2010

- Messages

- 2,357

- Reaction score

- 931

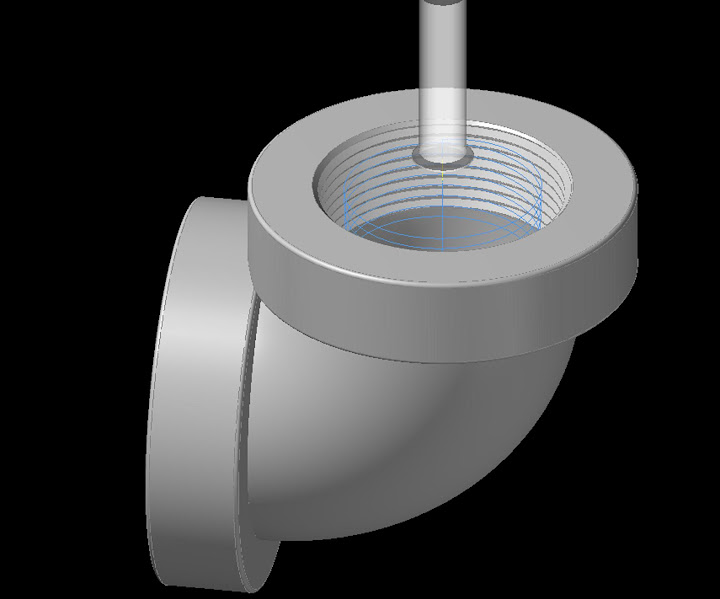

Im slowly beavering my way through Solidworks books & tutorials towards doing some model engine type 3D modeling, hopefully soon. One aspect that is still not clear to me is the issue of integrating typical fasteners into assemblies & how they are best represented. What I mean is, SW has an awesome selection of hole tools from drop-downs menu's. You can specify bolt types, threads, countersinks, counter bores, metric/imperial etc. & it will sink the appropriate tap drill or clearance size holes no problem. So far so good, thats what I want represented on the drawings.

But now what about the fastener itself? For example, If I now want to bring in a representative 4-40 socket cap screw into the assembly & mate it to this tap hole, are there (free) catalogs of fasteners available? Ive found some public domain type fasteners, usually from vendor lists. But sometimes they dont offer smallish sizes to what model engineers would use or graduated stock/purchase lengths. Also (I might be wrong here) it appears they have the full helical thread detail on them? If so, Im thinking this is overkill & just making assembly files unnecessarily large & complex. Im not intending to do strength calculations. My hunch is a suite of blank bolt shanks with cosmetic threads would be good. Are these available? If so, are they sized to typical thread ODs & then assembled as a coincident (interference) fit into the target tapped hole?

Hopefully from some folks who do this for a living can steer me down the right track. Im pretty sure I could draw some generic fasteners from specs to build a personal parts library, but seems like extra work. Using SW-2011 btw.

But now what about the fastener itself? For example, If I now want to bring in a representative 4-40 socket cap screw into the assembly & mate it to this tap hole, are there (free) catalogs of fasteners available? Ive found some public domain type fasteners, usually from vendor lists. But sometimes they dont offer smallish sizes to what model engineers would use or graduated stock/purchase lengths. Also (I might be wrong here) it appears they have the full helical thread detail on them? If so, Im thinking this is overkill & just making assembly files unnecessarily large & complex. Im not intending to do strength calculations. My hunch is a suite of blank bolt shanks with cosmetic threads would be good. Are these available? If so, are they sized to typical thread ODs & then assembled as a coincident (interference) fit into the target tapped hole?

Hopefully from some folks who do this for a living can steer me down the right track. Im pretty sure I could draw some generic fasteners from specs to build a personal parts library, but seems like extra work. Using SW-2011 btw.