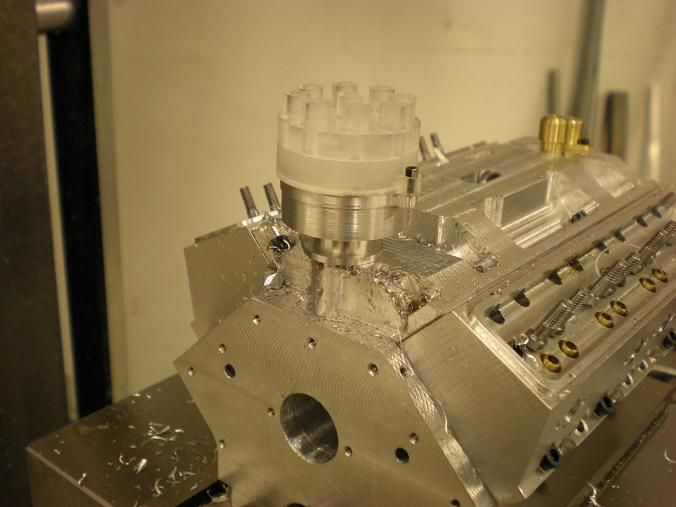

stevehuckss396 said:They will be available when It fires up and I know for sure it works.

Carb only $10

Engine, carb, display base, gas tank, radiator, etc! $50

Blower, drawings for the complete conversion $30

Does this sound fair? I don't want to gouge anybody but i do have a ton of work into them. I don't know!! I really don't know.

I for sure would be very interested for that price, running or not running, it wouldn't matter. Definately put me down for a set.

Loving this thread

Mick