Cheshire Steve

Well-Known Member

- Joined

- Mar 28, 2009

- Messages

- 69

- Reaction score

- 1

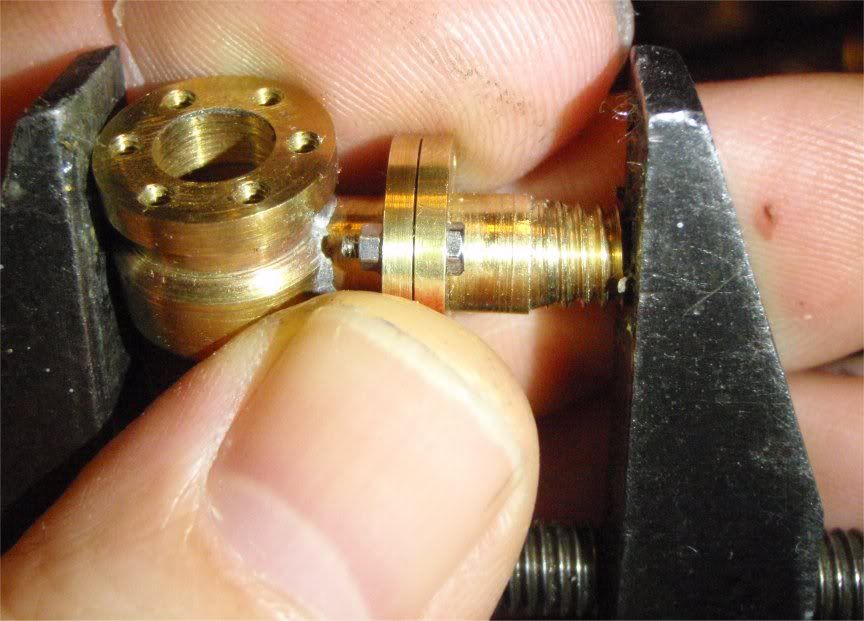

I thought I was being smart making a small stop valve for my little steam engine and using flanged steam pipe couplings. But actually getting the nuts on the 12BA bolts for the flanges is proving more challenging than I thought (they are 'small-head' bolts too). I wonder if anyone has any tips for starting the nut on the thread, I think I should be OK after that. I think the main problem is that the nut and bolt head are quite close to the pipe, so I can't get my fat fingers in, though both just have sufficient clearance to rotate.

Its at times like this when I get a strong urge to do larger scale modelling .. like 1:1

Steve

Its at times like this when I get a strong urge to do larger scale modelling .. like 1:1

Steve