M

MadKad

Guest

Hi, I am unsure if questions are ok here really, sorry if not.

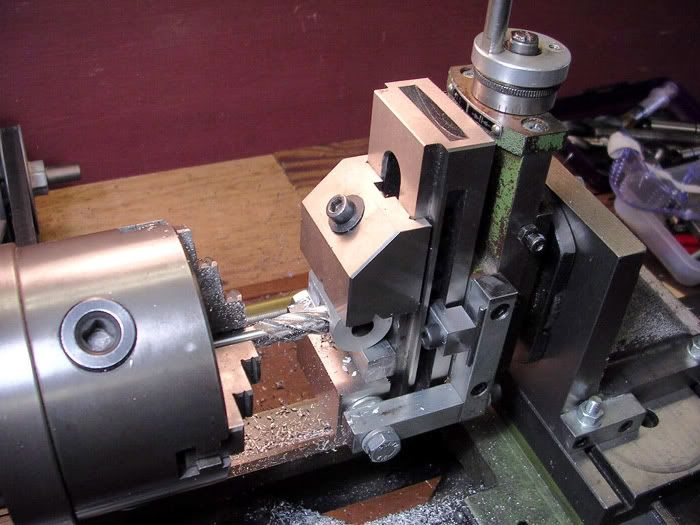

I own a new Sieg C2 lathe and I know that for the C3 they do a mill attachment, I have never seen one for the C and am very sure they dont make one, but I was wondering if I could some how add one with adapting and moding?

Has any one done this?

Would it be worth the work and do you think it would be cheaper than buying a good lathe?

Sorry for all the questions or daft ones, I dont have a big shop and think it would save space for me.

I own a new Sieg C2 lathe and I know that for the C3 they do a mill attachment, I have never seen one for the C and am very sure they dont make one, but I was wondering if I could some how add one with adapting and moding?

Has any one done this?

Would it be worth the work and do you think it would be cheaper than buying a good lathe?

Sorry for all the questions or daft ones, I dont have a big shop and think it would save space for me.