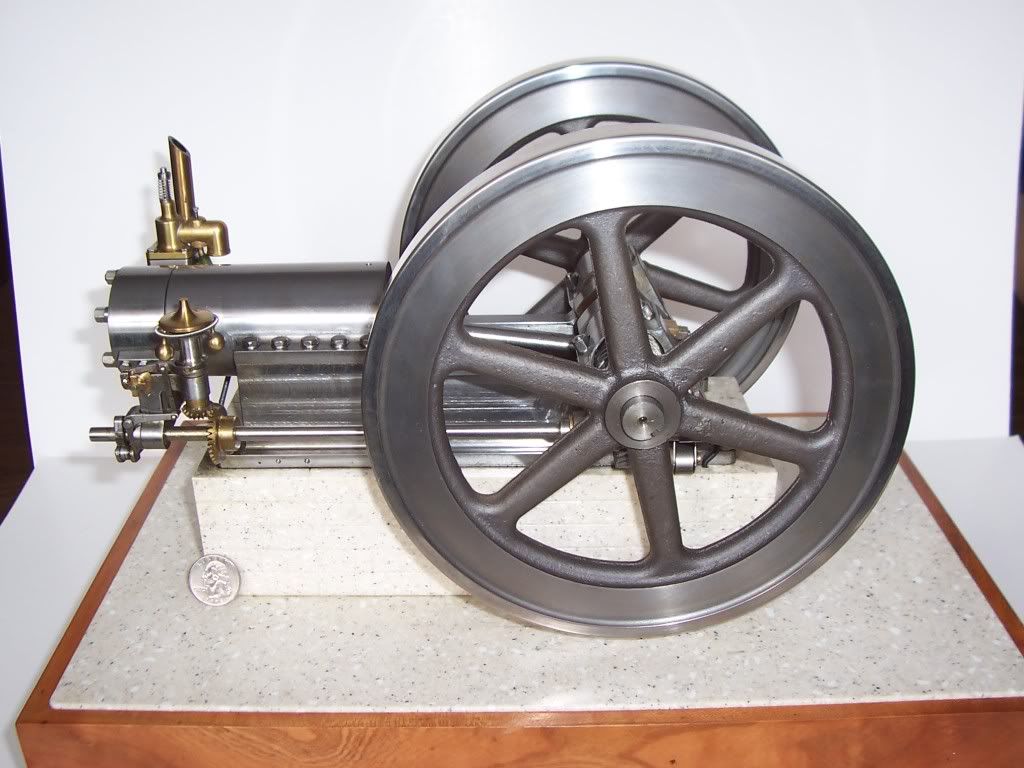

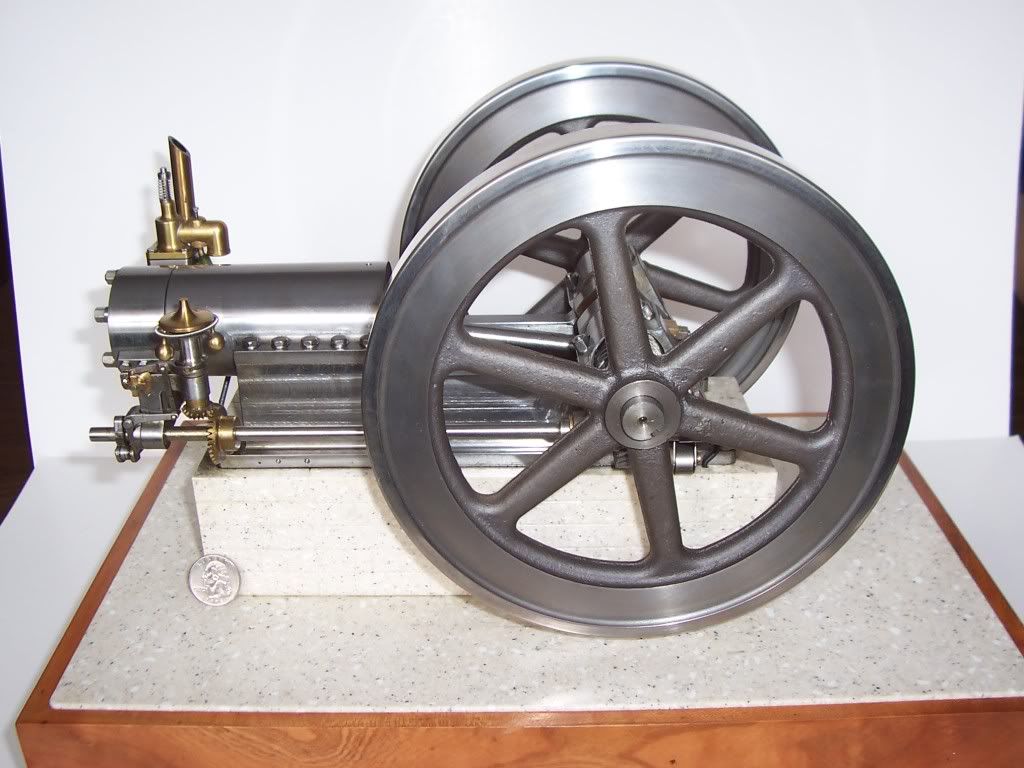

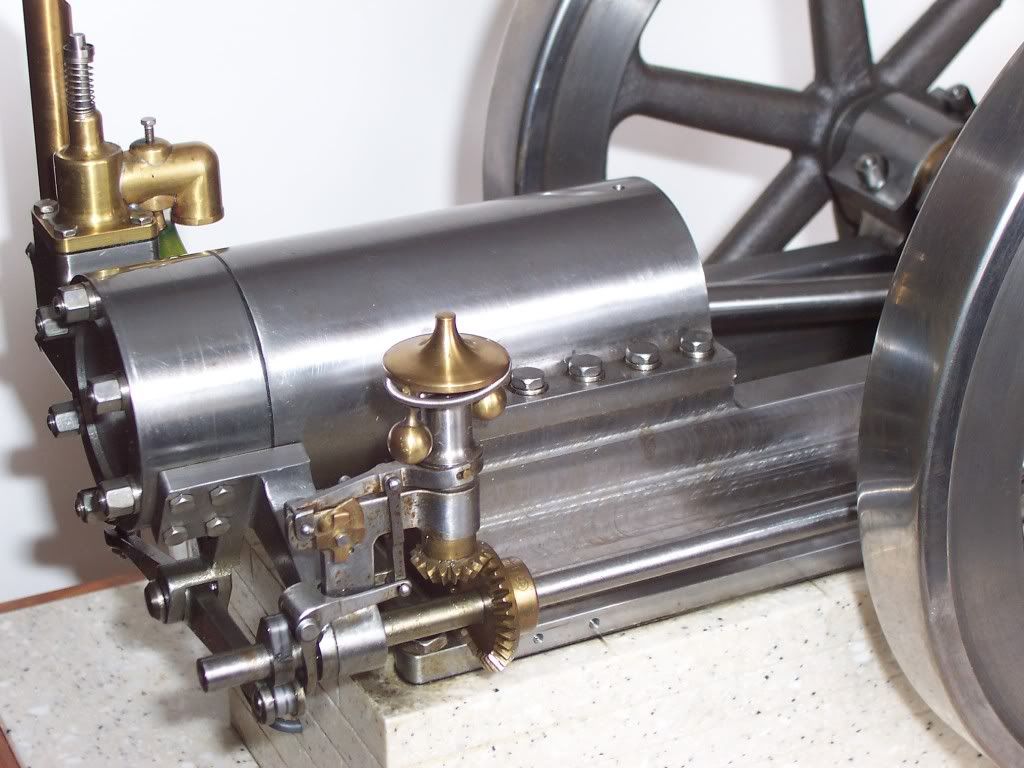

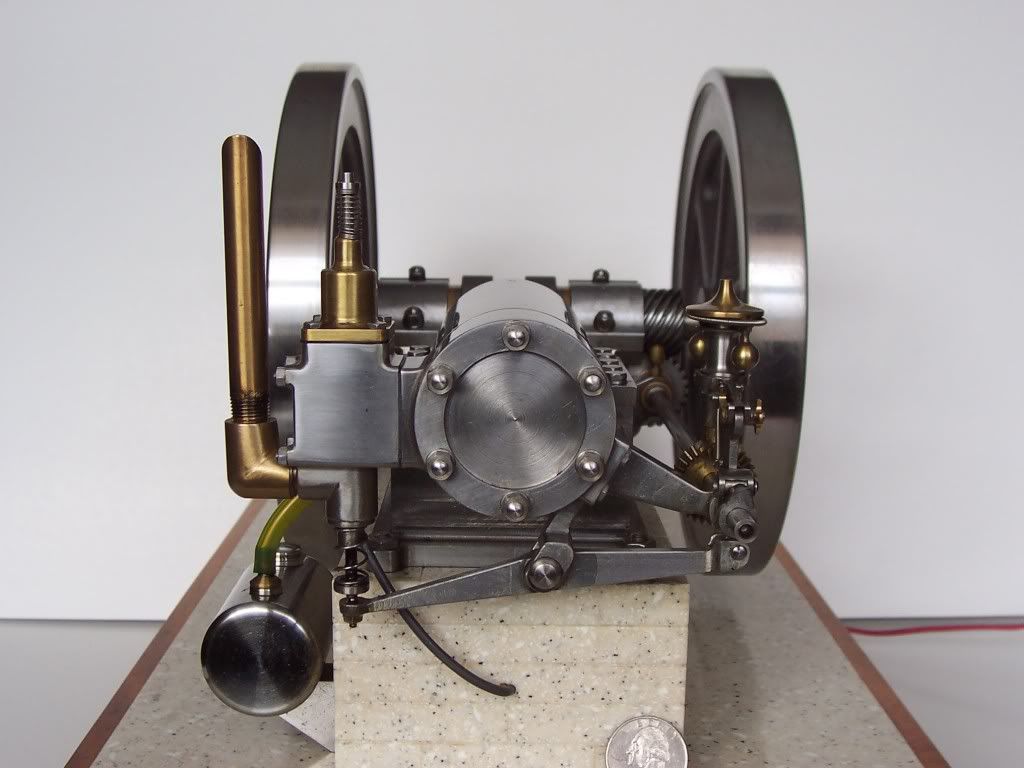

I built this scratchbuilt sideshaft hit-miss engine a couple of years ago. It has a 1.25" bore by 2" stroke. The flywheels are castings I picked up at a show and the rest of the engine is from barstock. I bought the helical gears from Paul Diebold (they are from his Vaughn). The frame was made from a solid piece of CRS as were most of the components. I figured I'd leave it unpainted to show there were no castings other than the flywheels. It was a fun build with very few problems but alot of hand work. I didn't produce any drawings for this engine, I made it just to see if I could do it. I used a 2:1 bevel gearset from Boston Gear to operate the governor but should have used a 3:1 instead. It could use more action at the flyballs. It does run well and best when warm. Thought you may like to see it. Dave