- Joined

- Dec 14, 2007

- Messages

- 1,181

- Reaction score

- 31

Nice score Steve!

Mine is very similar, made in Taiwan, it's worked well for me.

Here are some pretty heavy cuts in aluminum nickel bronze;

[ame]http://www.youtube.com/watch?v=rP4GZWUEJ3E[/ame]

KustomKB said:Nice score Steve!

Mine is very similar, made in Taiwan, it's worked well for me.

Here are some pretty heavy cuts in aluminum nickel bronze;

http://www.youtube.com/watch?v=rP4GZWUEJ3E

KustomKB said:Mine is very similar, made in Taiwan, it's worked well for me.

steamer said:The chuck mounts on the 7 degree 7.5 minute taper and when you pull it home.

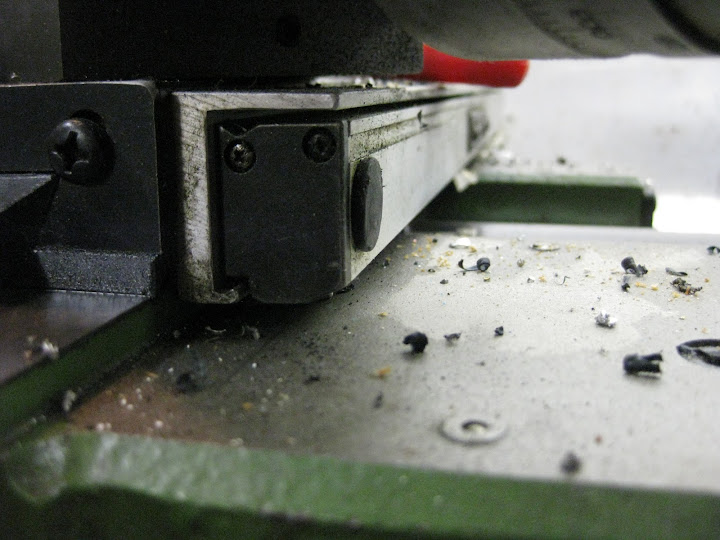

Billzilla said:It's got a magnetic XY sensor system on it though, so I can put the cutting tool back to within 0.001" quite accurately.

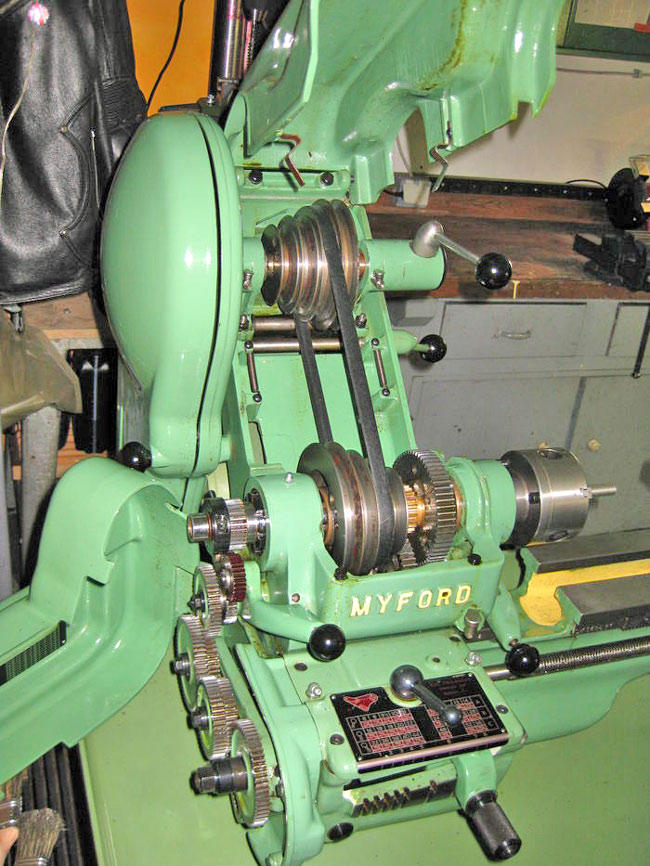

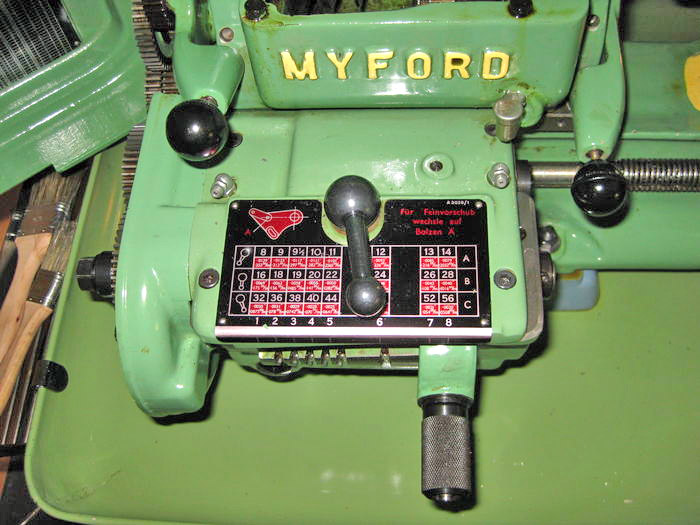

Mine is a Myford Super 7,made in 1973.

It came with a Norton gearbox.

I bought this British beauty in 2009.

Over the last two years I did some modifications to it,making it even more handy

than it has been anyway.

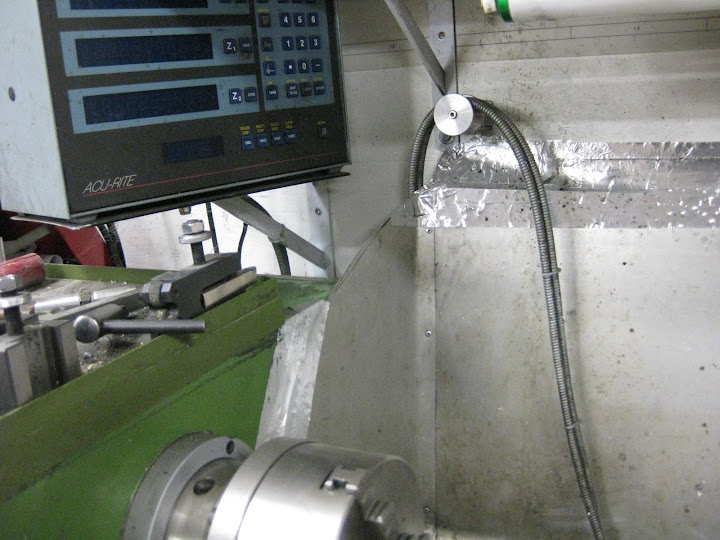

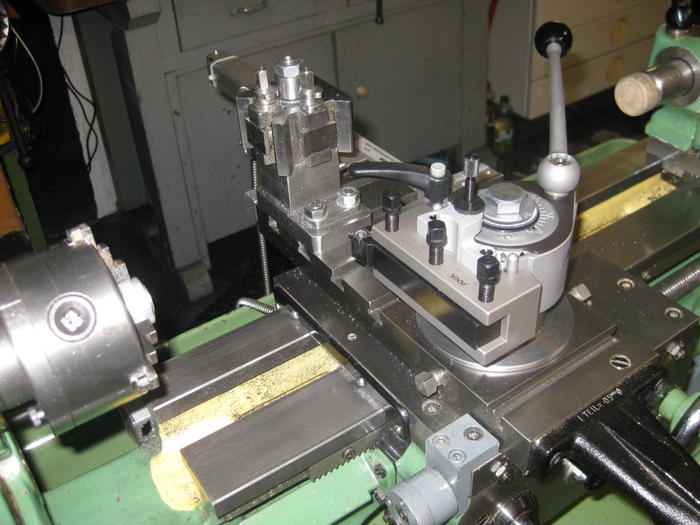

Axa QCTP and a rear toolpost:

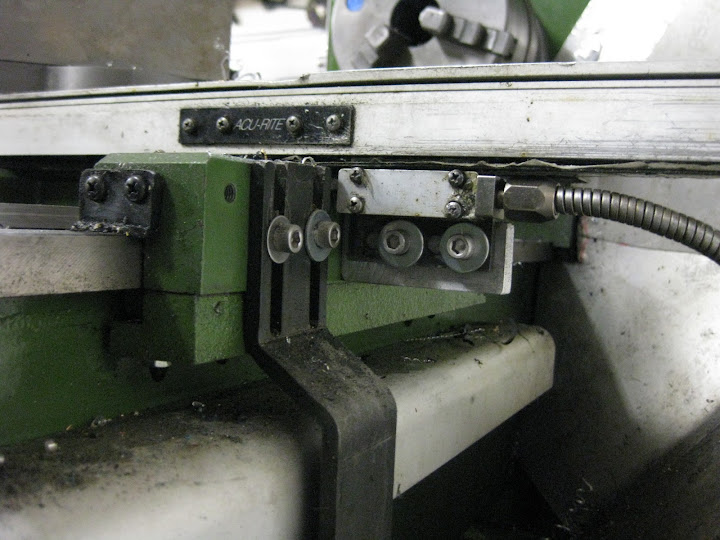

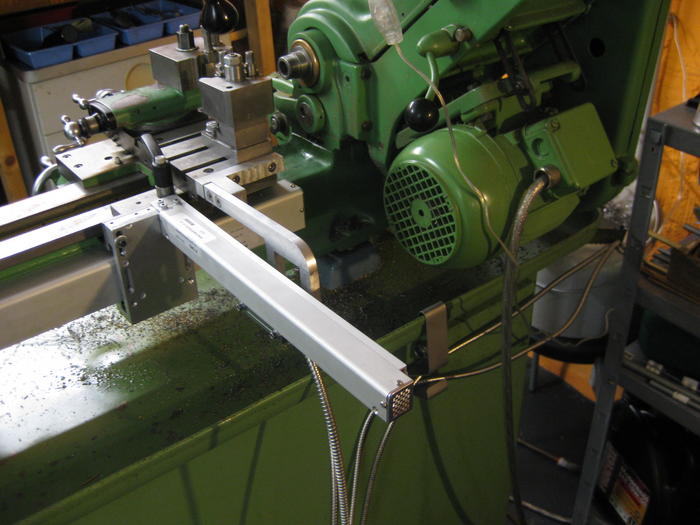

SINO DRO:

I really love that lathe and it´s so sad that the Myford Company is now history.

Cheers,Ralph

Hi,

so, here is my contribution to this murderthread, nothing too exciting though I'm afraid

My first one was a proxxon pd 360, a popular brand for small precision lathes in germany. Followed by a myford super 7 with extra long bed (makes a good rest for the tailstock)

cheers

christoph

Comparing the Emco to a shoptask is like comparing a BMW Motorcycle to a little chinese scooter.

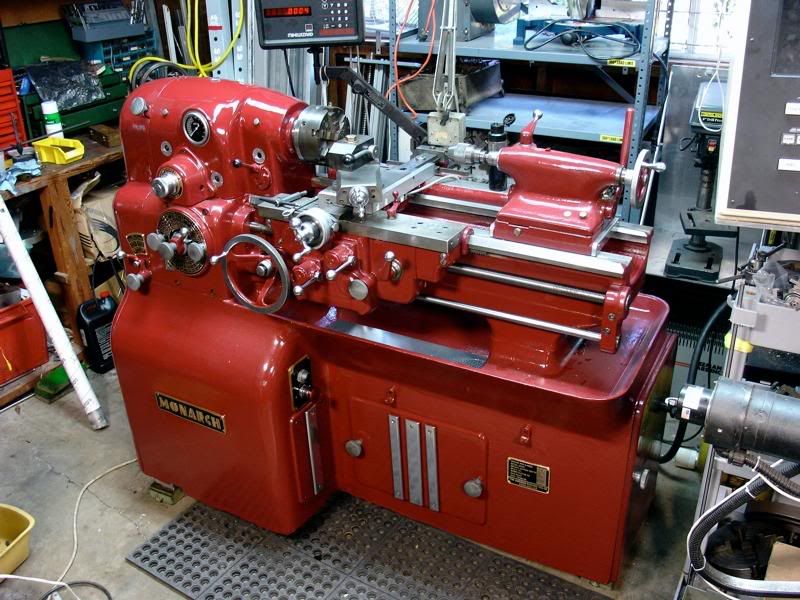

Heres a pic of my toy... Just finished going through her.

For those who dont know its a Monarch 10EE

One thing you have to remember in comparing your Monarch to any of the current small machines from China, is that your machine was built during WW II when the US was gearing up for war production and there was no consideration for cost. Your machine was built with tax dollars. If you were to try and build a similar machine in today's market, the price would be so high that only the top 1% could afford one.

That is true of ALL high quality INDUSTRIAL equipment when brand new.the price would be so high that only the top 1% could afford one.

Enter your email address to join: