Tin Falcon

Well-Known Member

- Joined

- Jul 9, 2007

- Messages

- 7,207

- Reaction score

- 787

That looks like a nice little board. I like my gecko but the price is right and should do fine on a small lathe.

Tin

Tin

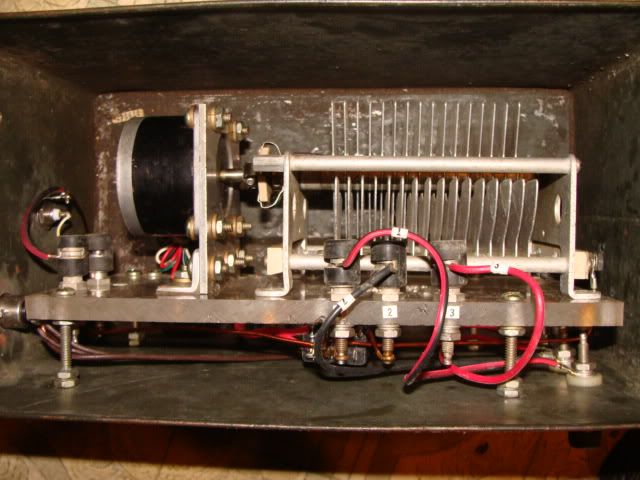

Here is a picture of a stepper motor driven capacitor used to remote tune an antenna. The interface box contained a stepper motor driver and a radio data port logic controller. As the radio operator changed frequency the computer would read the radio data port and drive the stepper motor keeping the antenna precisely tuned to the radio's frequency. It's still in operation after 10 years of use. It's mounted in a 50 cal ammo can.metalshaper said:DK,,

Jumping into the step motor/CNC world..

Enter your email address to join: