- Joined

- Oct 20, 2010

- Messages

- 913

- Reaction score

- 132

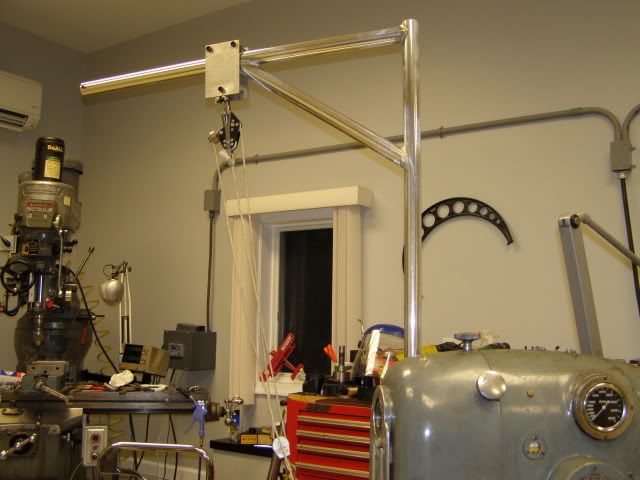

I wanted to share some things that work for me in the shop. As a T-3 Quad. (place your right hand over your heart, T-3 is everything below you thumb is paralized) arm strenght is a real problem, with no abdominal control, moving or lifting require one hand to hold onto the chair, the other to do the work.

The handle in the center of the door makes it much easier to close as the chair goes through.

This is a HF Hydraulic table, converted to hand pump

Being in a chair you need extra room to get around, this shelf unit rolls, and the shelves are on BB slides that move out so I can pick the chucks up with the lift.

The Tool Grinder is on a BBQ cart on wheels, just sping the cart to use each end of the grinder

The DP is on wheels as well

[

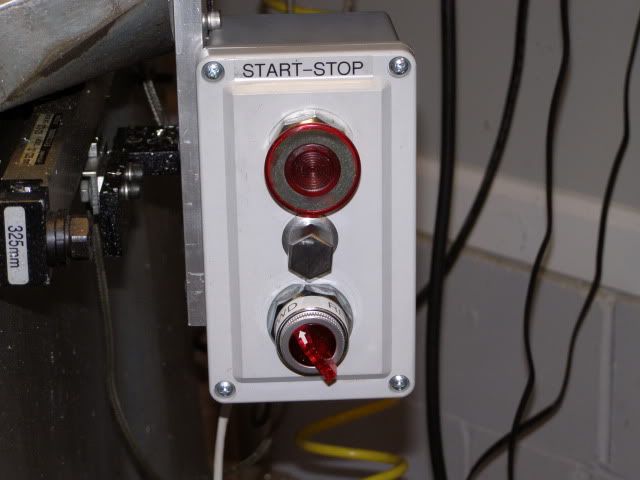

A power drawbar for the Mill is the only way to go,

A VFD makes control of the Mill much easier, this is mounted on the saddle, just below the table

While I could reach the depth handwheels with my grabber, lowered and 2:1 ratio makes it nice

The handle in the center of the door makes it much easier to close as the chair goes through.

This is a HF Hydraulic table, converted to hand pump

Being in a chair you need extra room to get around, this shelf unit rolls, and the shelves are on BB slides that move out so I can pick the chucks up with the lift.

The Tool Grinder is on a BBQ cart on wheels, just sping the cart to use each end of the grinder

The DP is on wheels as well

[

A power drawbar for the Mill is the only way to go,

A VFD makes control of the Mill much easier, this is mounted on the saddle, just below the table

While I could reach the depth handwheels with my grabber, lowered and 2:1 ratio makes it nice