ChooChooMike

Well-Known Member

- Joined

- Jan 5, 2008

- Messages

- 864

- Reaction score

- 13

Cool I get to post the 1st thread on the CNC board :big:

OK, not exactly the highlight of my day :

:

I'm a Sherline user and will CNC my mill at some point in the future.

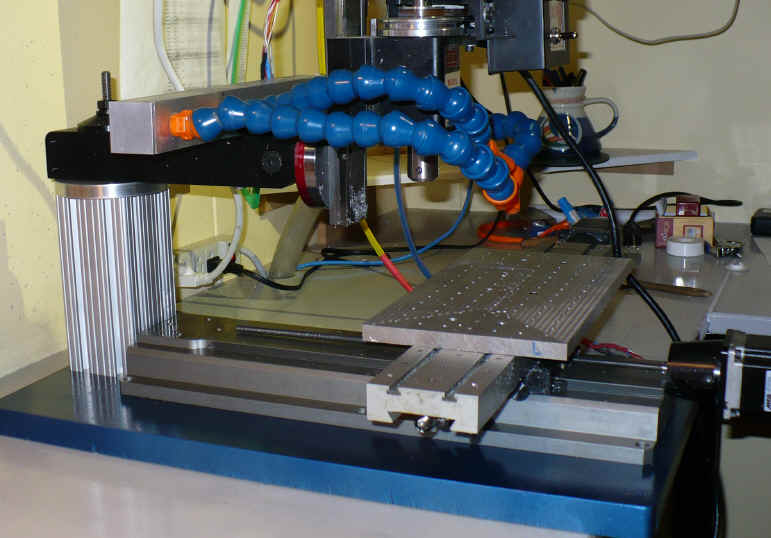

Here's some nice videos from a guy name Alan Lilly showing converting his Sherline mill to CNC using the Sherline CNC upgrade kit.They are both 12 minutes long, but worth a watch if you are a Sherline user and have any interest in CNC Thm:

http://www.panofish.net/2009-02-15_Sherline_CNC_1/index.html

http://www.panofish.net/2009-02-18_Sherline_CNC_2/index.html

Mike

OK, not exactly the highlight of my day

I'm a Sherline user and will CNC my mill at some point in the future.

Here's some nice videos from a guy name Alan Lilly showing converting his Sherline mill to CNC using the Sherline CNC upgrade kit.They are both 12 minutes long, but worth a watch if you are a Sherline user and have any interest in CNC Thm:

http://www.panofish.net/2009-02-15_Sherline_CNC_1/index.html

http://www.panofish.net/2009-02-18_Sherline_CNC_2/index.html

Mike