Dan Rowe

Well-Known Member

- Joined

- Feb 12, 2010

- Messages

- 594

- Reaction score

- 18

The subject of Shay locomotives has been my prime focus for a while now. I have drawn several Shays from the Lima Locomotive Works drawings and have made a scrap bin of failed parts.

The one I am working on now is Shop Number 2800. This was a 10 ton Shay with 2-6"x10" cylinders that went to the Mapleton Tramway in Queensland Australia.

S/N 2800 image posted with permission of the Allen County Historical Society Lima Ohio.

The scale of the build is 7/8" to the foot for G1 track. The Mapleton Tramway was a 2' line that ran in a remote area of Queensland and it serviced the comunity. The book by John Knowles "The Mapleton Tramway" covers the history of this tiny pike very well.

My drawings have been printed in "Steam in the Garden" starting in issue #100 with a double fold out showing all 4 sides in 7/8" scale. Most of the drawings in the articles are 7/8" scale versions of the LLW drawings with full size dimensions so they can be used for any scale. The next issue #114 will have the boiler prints for the two Shays used on the tramway. They had a copper fire box and brass tubes, and were built to the Board of Trade Rules.

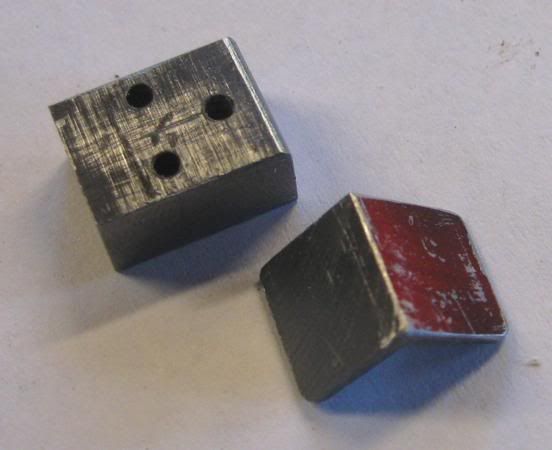

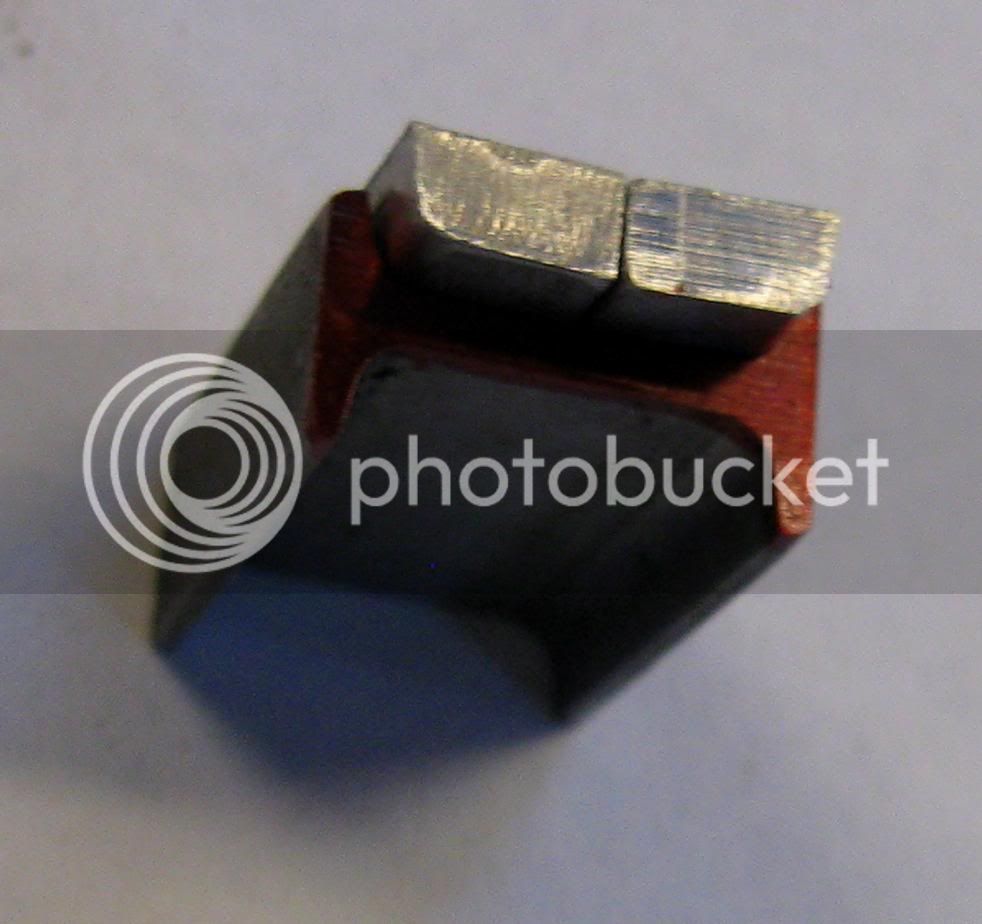

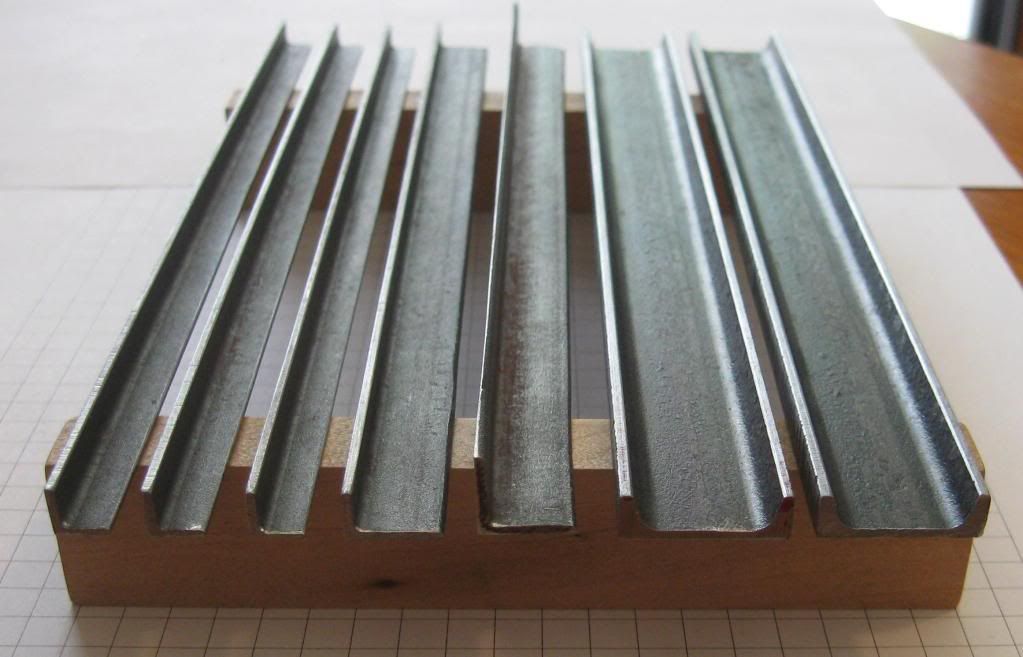

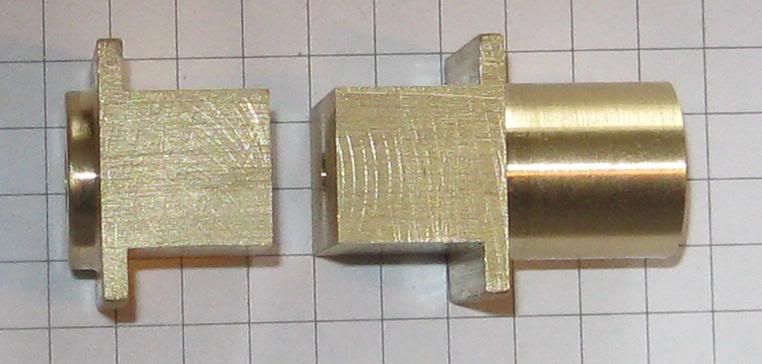

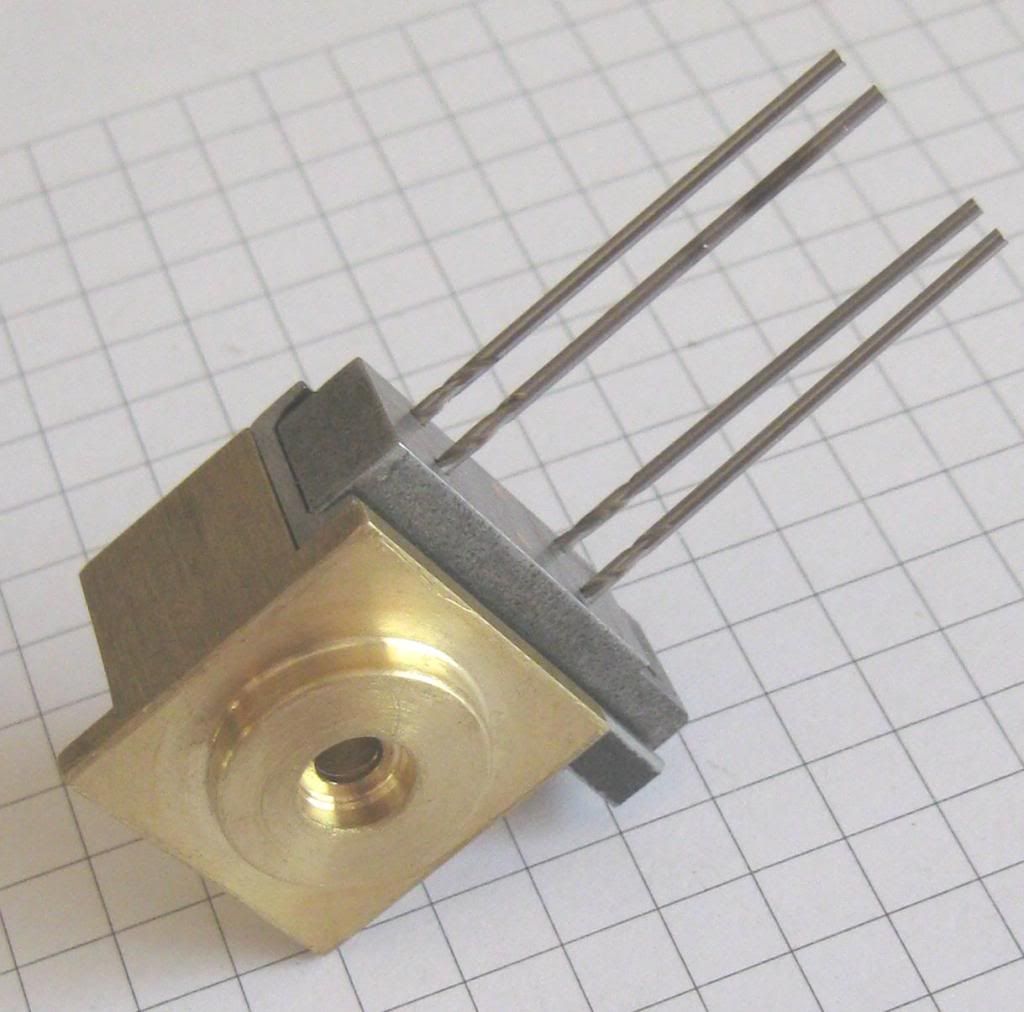

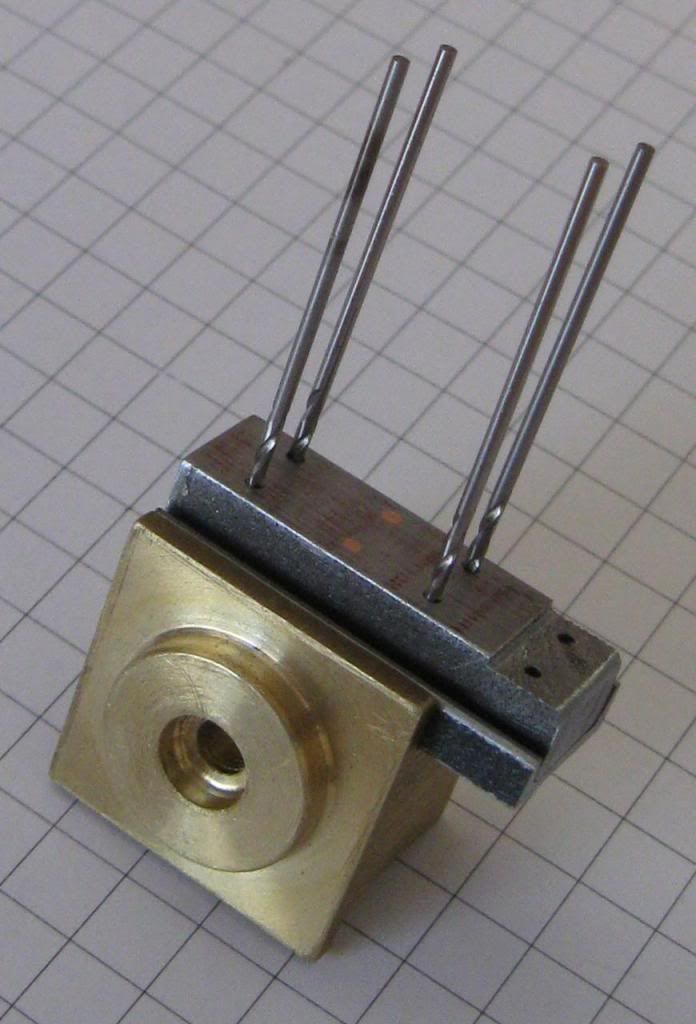

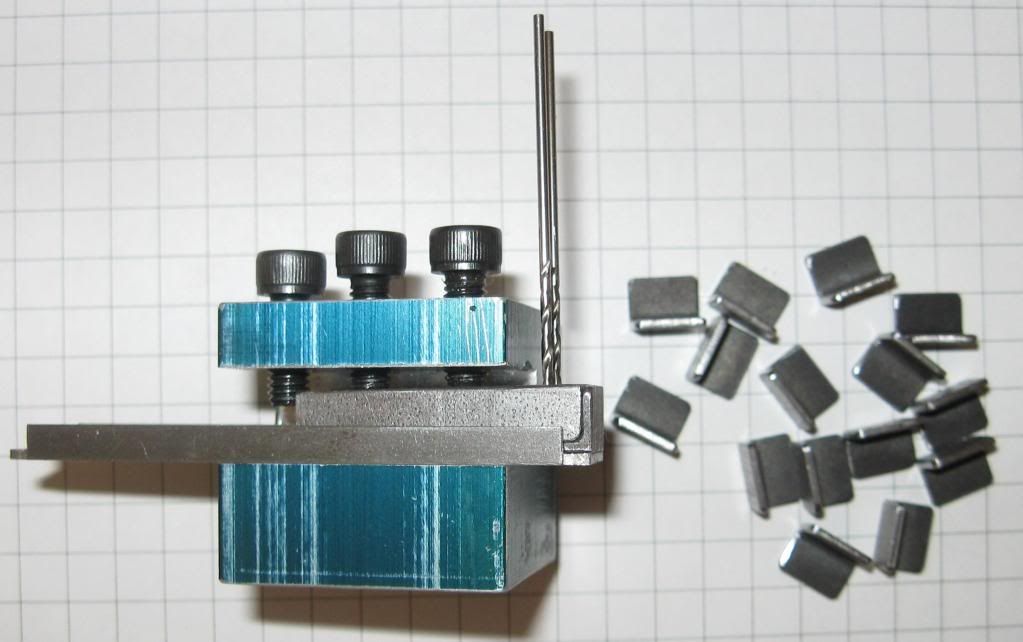

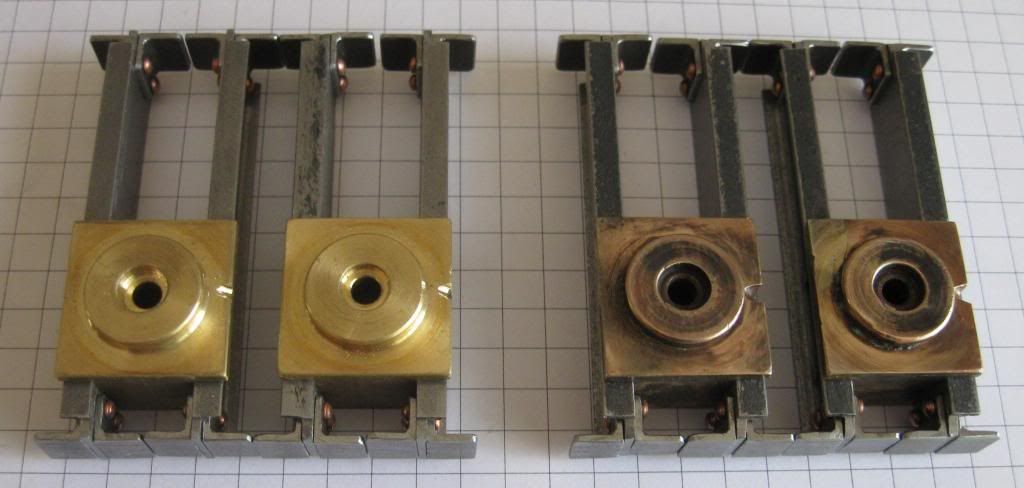

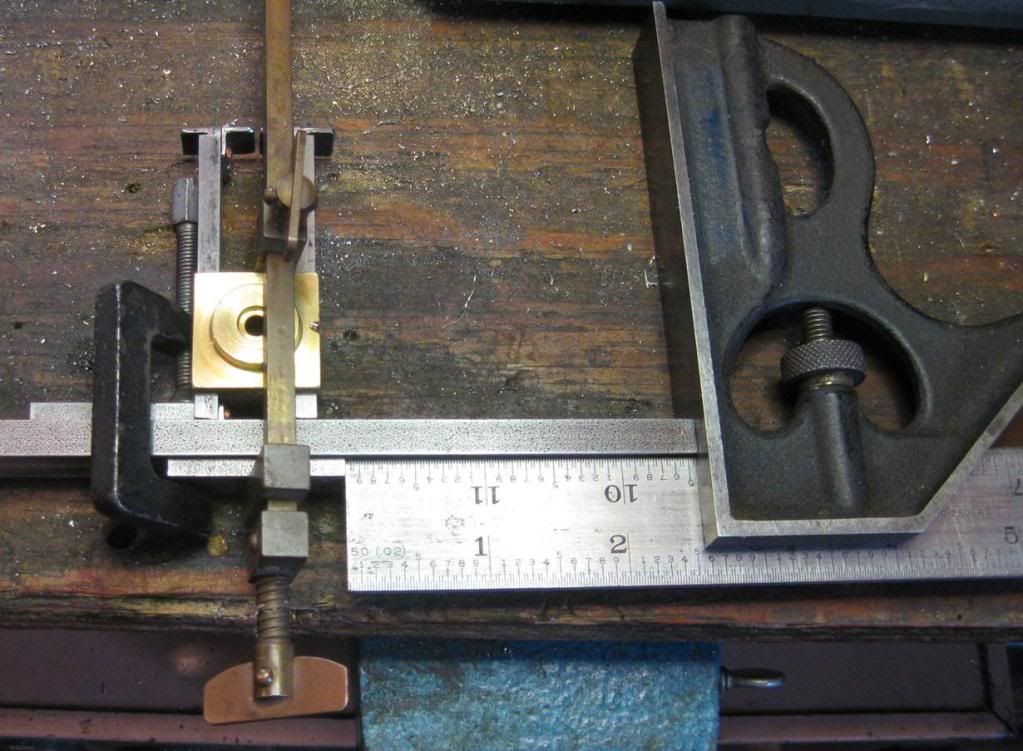

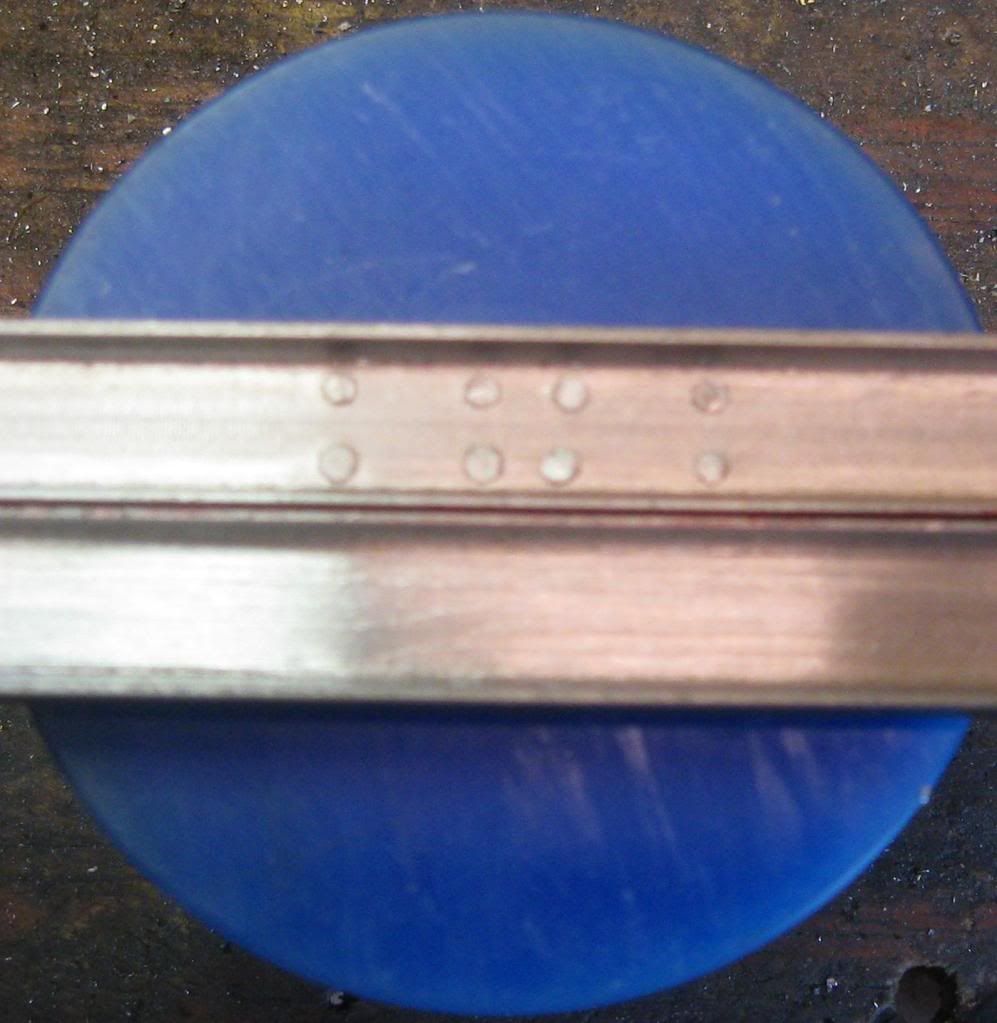

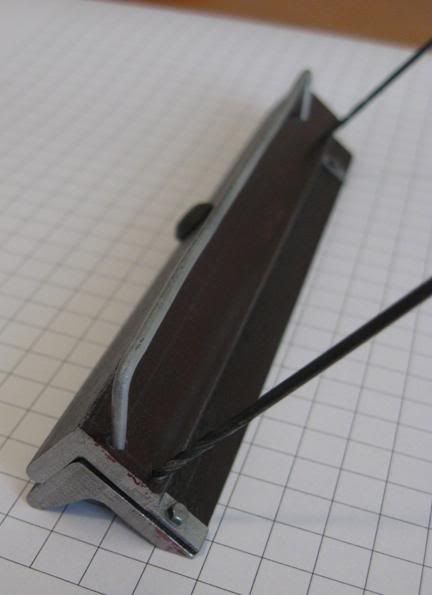

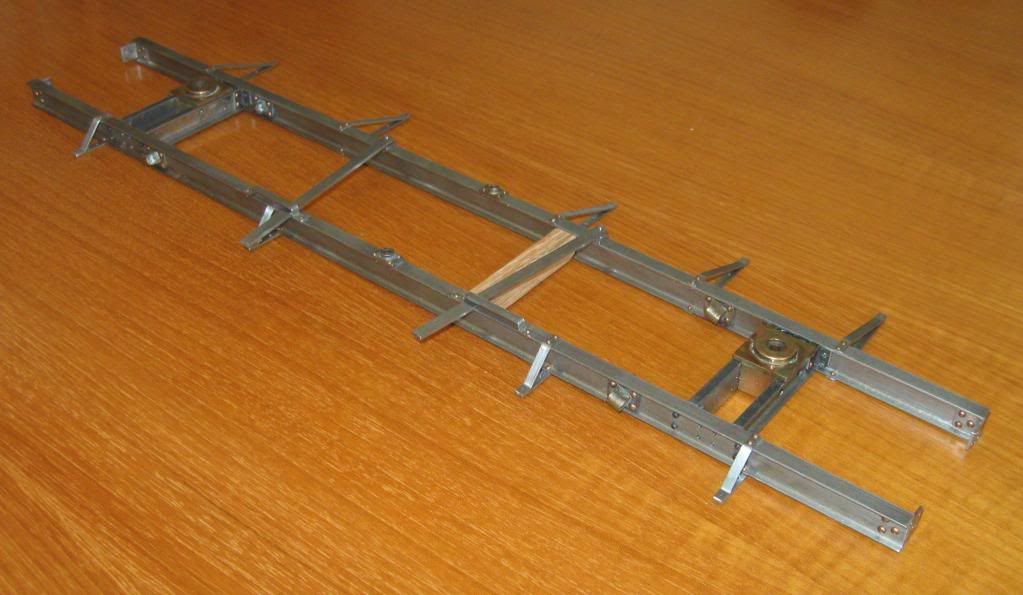

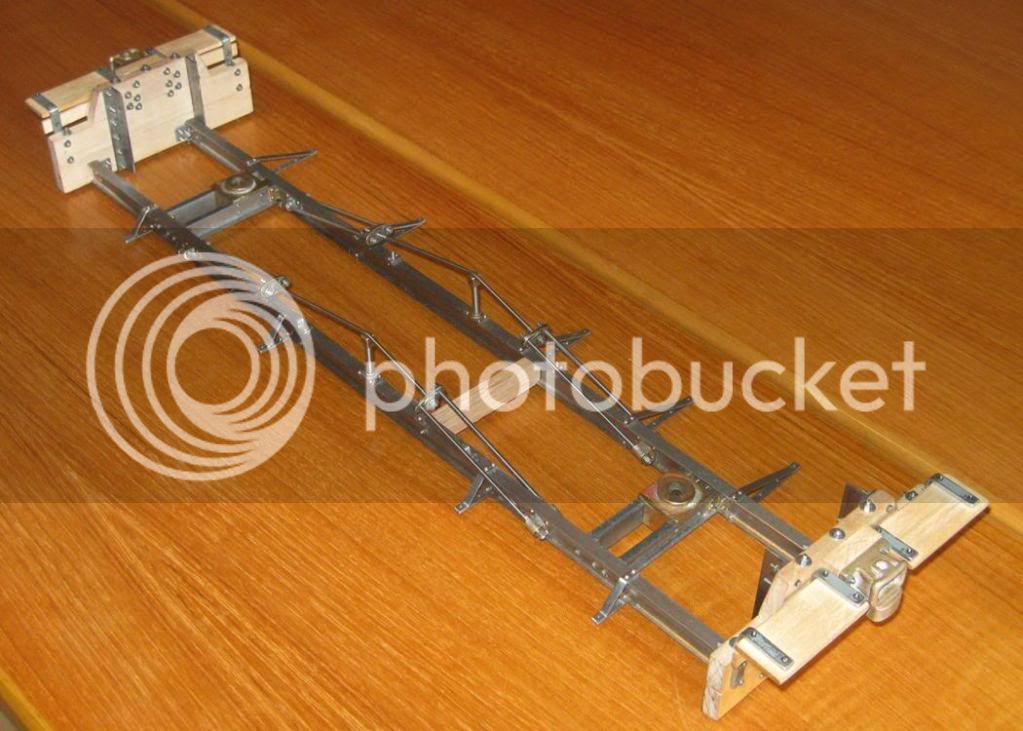

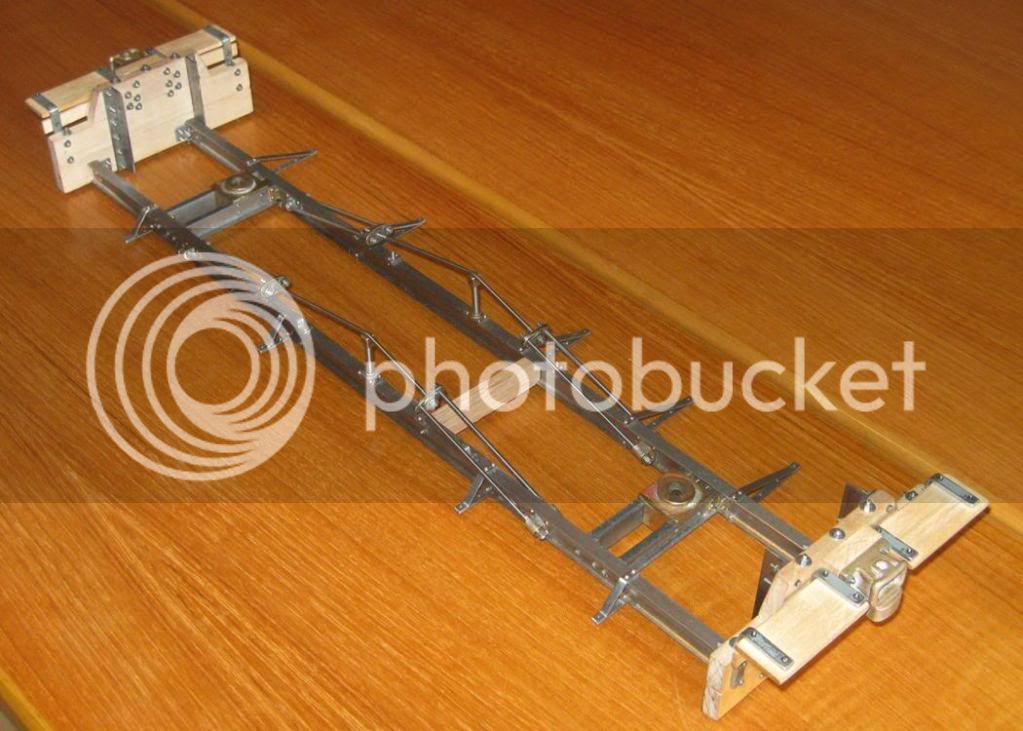

I am nearly finished with the articles and I hope to have a lot more shop time to build this Shay. The photos show my work on the frame to date.

Dan

The one I am working on now is Shop Number 2800. This was a 10 ton Shay with 2-6"x10" cylinders that went to the Mapleton Tramway in Queensland Australia.

S/N 2800 image posted with permission of the Allen County Historical Society Lima Ohio.

The scale of the build is 7/8" to the foot for G1 track. The Mapleton Tramway was a 2' line that ran in a remote area of Queensland and it serviced the comunity. The book by John Knowles "The Mapleton Tramway" covers the history of this tiny pike very well.

My drawings have been printed in "Steam in the Garden" starting in issue #100 with a double fold out showing all 4 sides in 7/8" scale. Most of the drawings in the articles are 7/8" scale versions of the LLW drawings with full size dimensions so they can be used for any scale. The next issue #114 will have the boiler prints for the two Shays used on the tramway. They had a copper fire box and brass tubes, and were built to the Board of Trade Rules.

I am nearly finished with the articles and I hope to have a lot more shop time to build this Shay. The photos show my work on the frame to date.

Dan