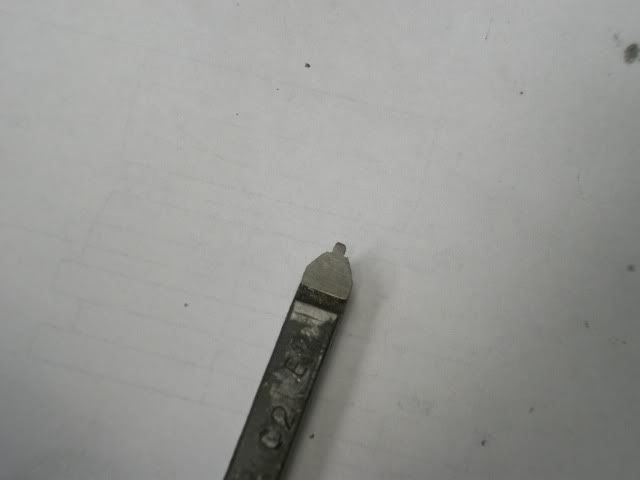

I just sharpened all of my carbides on my new green wheel. Couldn't find my expensive HEPA air mask, so I tied an old T shirt over my nose. I looked a bit like the Lone Ranger, and wondered what the nosy neighbours who can see into my garage were thinking. Of course, this made my glasses fog up instantly, so I not only looked like an outlaw, I stumbled around a bit like Mr. Magoo----You get 10 points if you're old enough to know who Mr. Magoo is/was. My green wheel is 3/4" wide, and so as not to rub a groove in it, I moved the carbide tools back and forth a bit while I was grinding them. I think this is in direct conflict with what somebody posted earlier. All of my carbide tools LOOK sharper now. Of course, I don't know if they will cut anything now, but Hey, they were dull before anyways. They are cheap Chinese carbides, and were only sharpened across the end and on one side (Which I think is normal.) Of course now that I have sharpened 2 adjacent sides, they have one Hellish sharp point where the 2 egdes that were sharpened meet. I'm not shure if I should leave this sharp corner, or endevour to break it a bit----on my green wheel, of course.----Brian