Managed to motivate myself to hook up the fan in the box.

so that meant

1) remove old wires from a/c input jack and solder new ones on.

2) install terminal strips to hook wires to.

3) install standoffs for fan power supply (and find them first)

4) install fan power supply

5) hook main power supply, fan power supply and AC in to terminal strips.

6) make and install safety cover for terminal strips.

7) turn fan around so it would blow in instead of out.

and of course you need a photo.

the fan is from the old pc

the fan ps is from LMS came when i purchased a new fan for the Mill.

the terminal strips are from radio shack

a 4 for the hot then split an 8 in two for the neutral and ground.

there are 3 ,4 prong jumper strips connecting the wires (also from rs)

Main power supply is keiling

and the gecko is the black box in the background.

probably not NASA quality but Should be safe and functional.

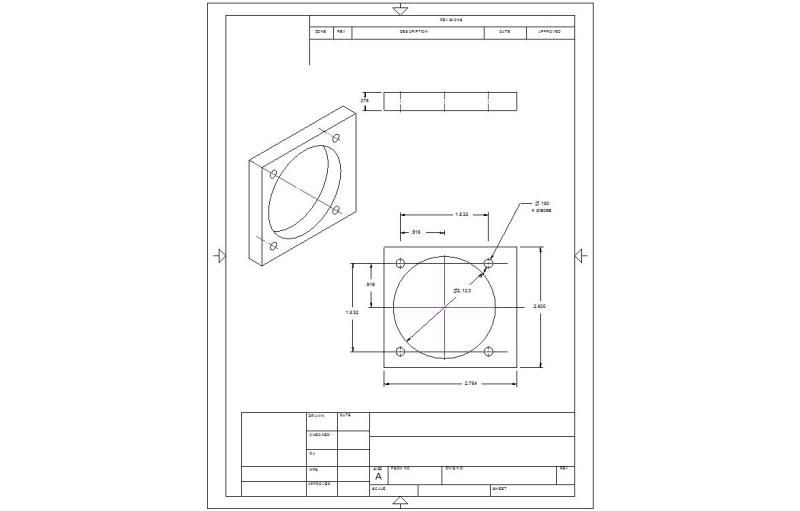

I made a drawing for the rotary table mount to add a stepper to that. Getting better with small parts on Albre.

I like being able to draw quickly to scale, helps visualize the details and shows problems before you make the part.

tin