Sam, thanks for checking in. I don't think I'm ready to have cooling fins cut in me just yet :

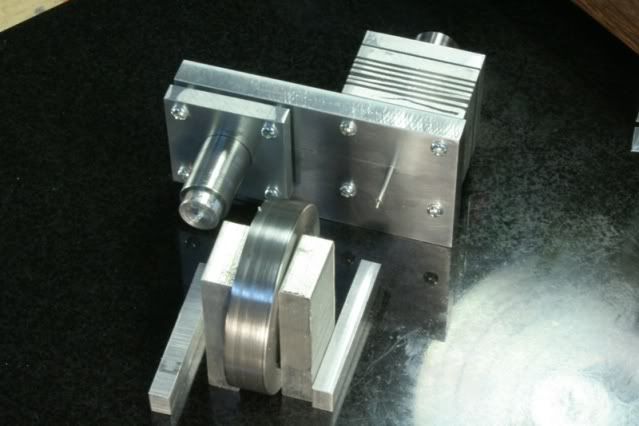

Thanks for the heads-up, Gail. I'm not satisfied with the current parts, so I may remake them. The displacer cylinder is nice and smooth, put the power cylinder seems to have a rough spot in it I didn't find till I made the piston. So, it looks like some lapping and a remake of the piston anyway.

I have a line on some graphite that is currently in someone else's hands, but it's been tagged for rocket engine nozzles. If I end up making some of the nozzles then I'll have a piece.

Until then, do you think 12L14 for the power piston will be OK? This engine is being built with learning in mind, so I'm open to any and all suggestions. My only limit is the materials on hand at the moment.

Thanks for the heads-up, Gail. I'm not satisfied with the current parts, so I may remake them. The displacer cylinder is nice and smooth, put the power cylinder seems to have a rough spot in it I didn't find till I made the piston. So, it looks like some lapping and a remake of the piston anyway.

I have a line on some graphite that is currently in someone else's hands, but it's been tagged for rocket engine nozzles. If I end up making some of the nozzles then I'll have a piece.

Until then, do you think 12L14 for the power piston will be OK? This engine is being built with learning in mind, so I'm open to any and all suggestions. My only limit is the materials on hand at the moment.