Philjoe5

Well-Known Member

- Joined

- Jul 12, 2007

- Messages

- 1,727

- Reaction score

- 321

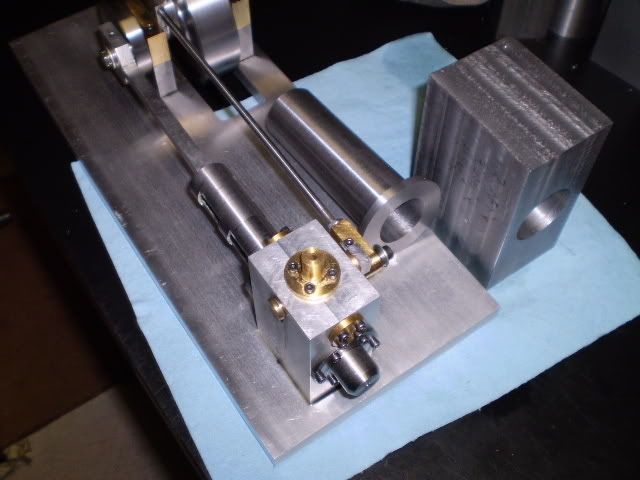

This idea of scaling up the horizontal mill engine kept nagging at me. I thought that when I started the walking beam engine Id forget about it. But as the famous blues singer John Lee Hooker said in one of his songs Its (music) in there (his head) and its got to come out. So I decided after spending a week doing some of the finer work on the walking beam Id take a break and start machining the 1.5 x scale horizontal mill engine. This engine will have a 1.500 bore x 1.875 stroke.

I think someone on this board said it. When you scale up by 1.5x, you are really scaling up by 1.5 x 1.5 x 1.5 = 3.38 (Sounds like a Marv to me)! So my 2.5 lb cylinder block becomes 8.5 lb!

Boring the crosshead guide was a challenge. Its about 4.5 long and I dont have a boring bar with that reach. So I drilled and bored from opposite ends. Even though I used the 4 jaw chuck, the meeting wasnt as clean as Id like. This is only a guide so a little extra clearance isnt such an issue.

Heres a photo of the new crosshead guide and cylinder block next to the original scale.

Im thinking this is going to be a great adventure. Im really pumped up about both engines. Both require different techniques, most of them new to me. This is what its all about!!!!

Cheers,

Phil

I think someone on this board said it. When you scale up by 1.5x, you are really scaling up by 1.5 x 1.5 x 1.5 = 3.38 (Sounds like a Marv to me)! So my 2.5 lb cylinder block becomes 8.5 lb!

Boring the crosshead guide was a challenge. Its about 4.5 long and I dont have a boring bar with that reach. So I drilled and bored from opposite ends. Even though I used the 4 jaw chuck, the meeting wasnt as clean as Id like. This is only a guide so a little extra clearance isnt such an issue.

Heres a photo of the new crosshead guide and cylinder block next to the original scale.

Im thinking this is going to be a great adventure. Im really pumped up about both engines. Both require different techniques, most of them new to me. This is what its all about!!!!

Cheers,

Phil