Dave, I make all sorts of polyurethane seals in my home workshop.

These are typically two part rapid curing resins which can be gravity poured.

Ideally vacuum degassed before pouring.

Typically I do mine in alluminium moulds and use an old truck oil filter and water filter as pressure / vacuum pots.

But you can create moulds in silicon or hard polyurethane about wax models or 3D "prints" - many ways of skinning this particular cat.

None of this is particularly difficult but a fair amount of knowing what works and what doesn't comes with experience.

I will be doing a post on this shortly.

You must use release agents unless you are using silicone moulds.

The polyurethanes come in various hardness grades from soft to rock solid and can be coloured.

Look up the "Smooth On" product range - which I have used extensively - but there are plenty of others available. If you find a local supplier of the resins you will normally find they can provide you with a wealth of "How To" information.

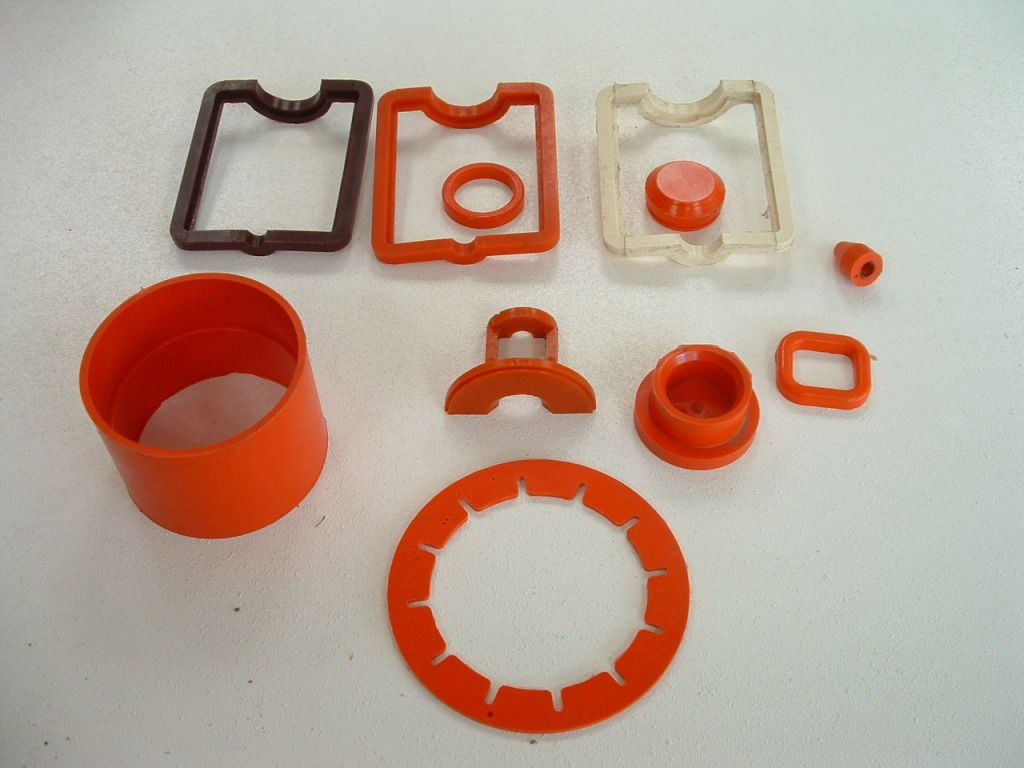

Some examples. The little conical dodahh at the top right even has a thread moulded into its base - this was a seal to test a fuel injector port on a machine I designed.

All the above are in 70 Shore "D" hardness which is a little softer than tyre rubber (90) and I would guess is exacly what you are looking for.

Polyurethane is resistant to most solvents and oils - handles temperature up to about 120°C well - thereafter is starts to soften and ultimately melts. I have made a number of "underhood" parts which have performed well.

Ken