I ran across this post a couple of days ago.

It caught my interest because I'm considering trying to build a rotary sleeve valve engine. I'm probably biting off more than I can chew as I'm kind of fresh to machining, but nothing ventured...

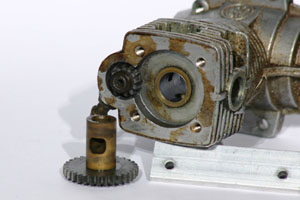

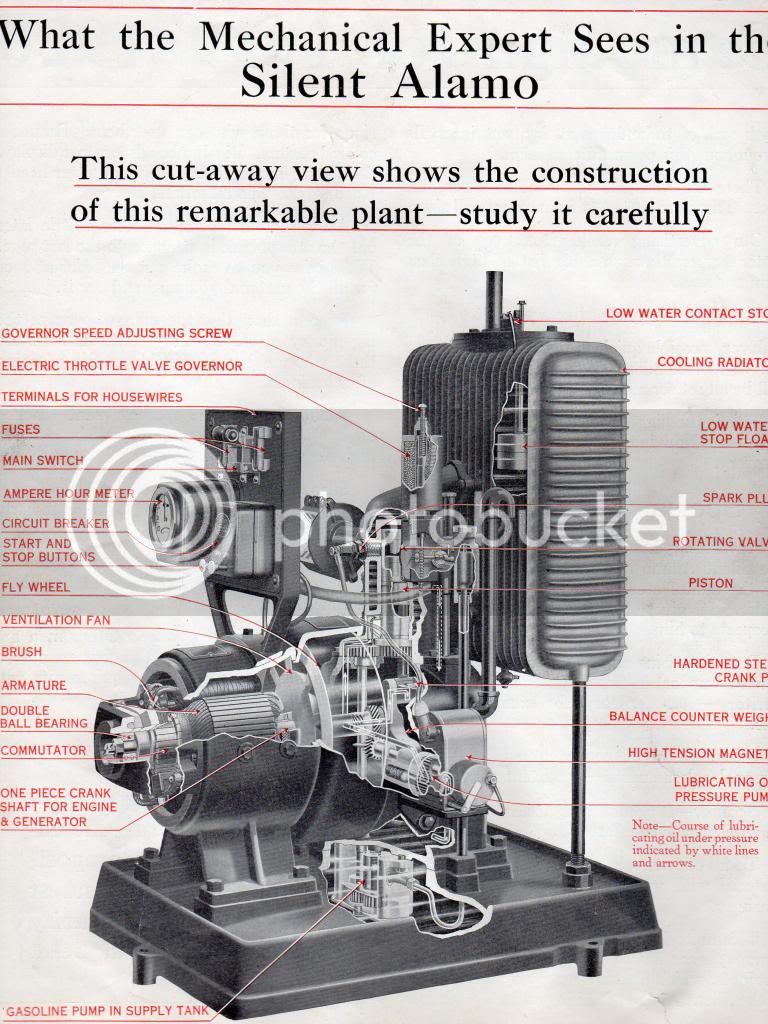

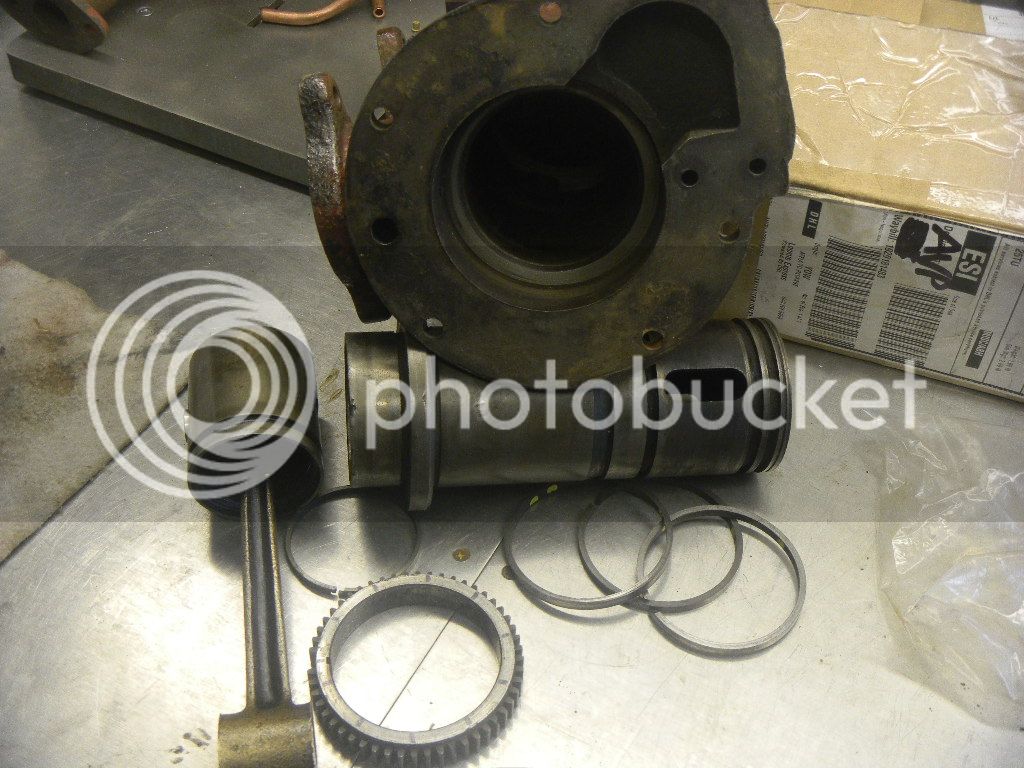

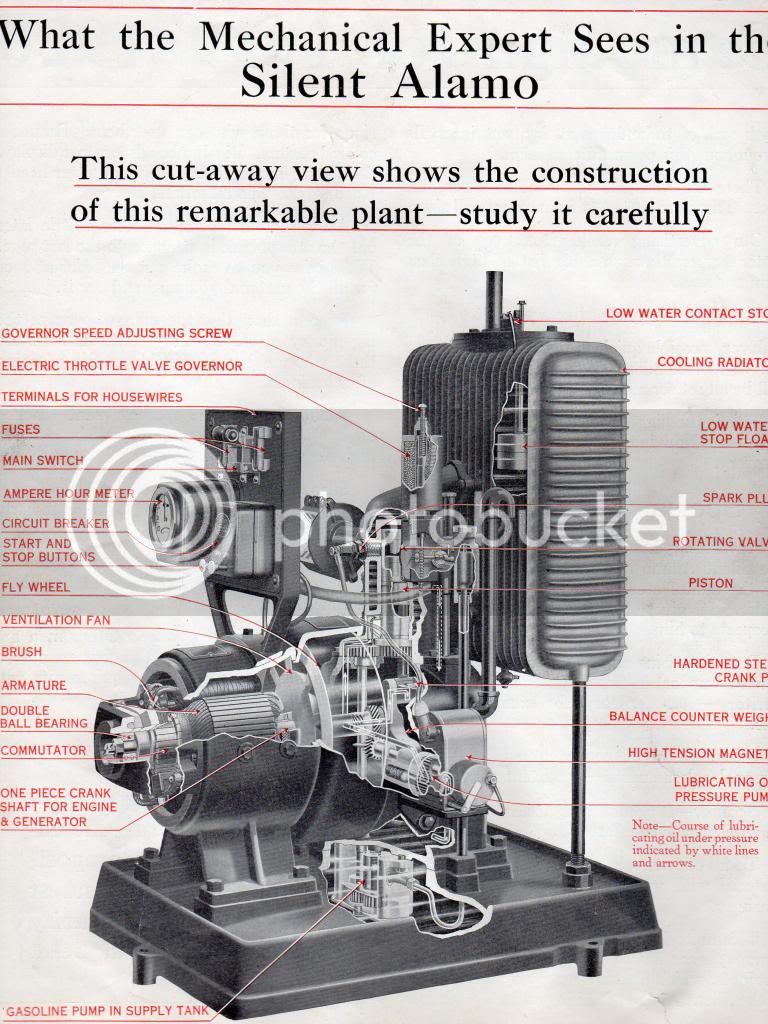

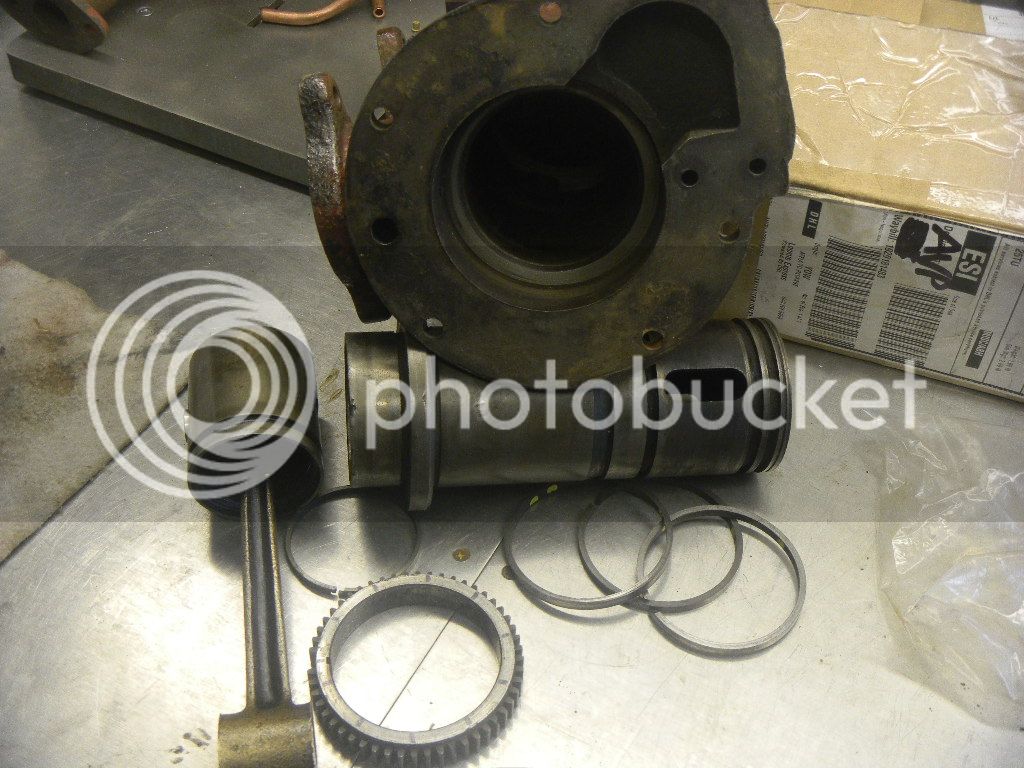

I have an early (1917) full size Alamo Electric Co. rotary sleeve valve engine which is currently partially disassembled to repair a broken tooth on the gear that drives the sleeve.

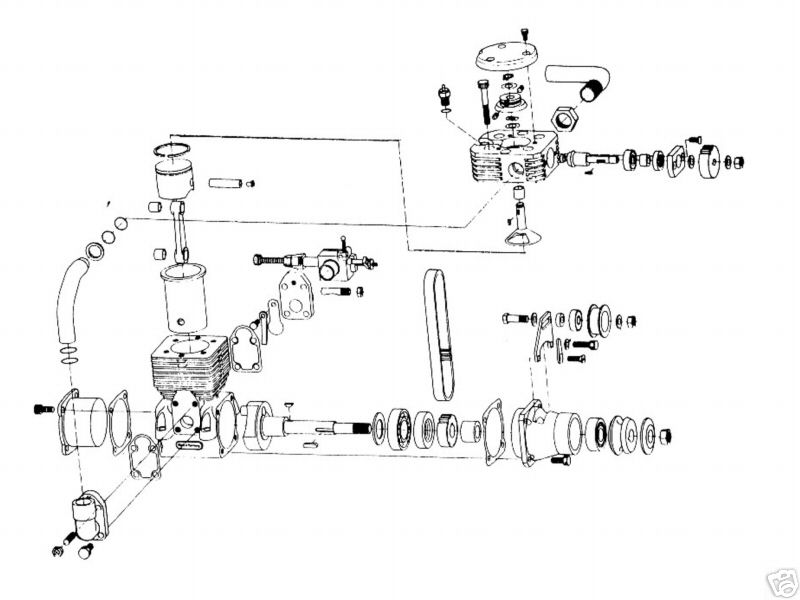

I'm not at all thinking of making a scale model of the entire unit, which is a 32 volt light plant.

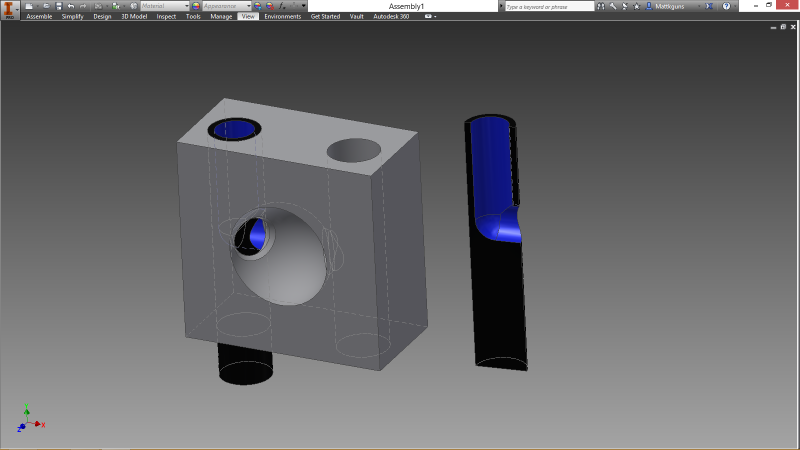

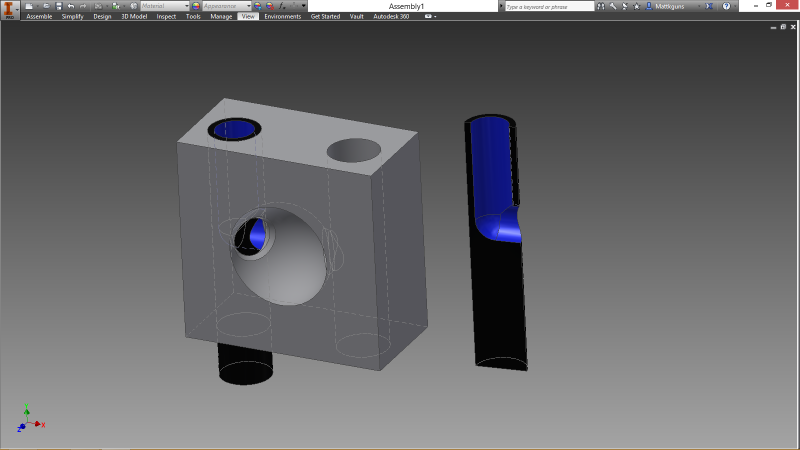

But rather, try to incorporate the sleeve valve and it's associated gearing into a horizontal side shaft design using the plans for my 1 1/4" bore Wyvern.

I've made some preliminary sketches, basically to make sure I could end up with a reasonably sized gearing to accomplish the 4:1 drive ratio for the sleeve.

The Alamo is 2 1/2" bore and should readily scale into half size which is ideal to fit into the size of the Wyvern.

The sleeve has two ports/slots that are directly opposed to each other at 180 degrees. The timing is accomplished by way of rotating past two ports (intake and exhaust) and the spark plug, all spaced evenly 120 degrees apart. Giving the engine one power stoke per two revolutions of the crank, making it a four cycle engine. Each port takes turn functioning as either spark, exhaust or intake. It should prove interesting if I can pull it off.

I've been searching to find info on rotary sleeve valving and haven't yet found anything quite like this.

I'm considering air cooled as water cooling seems to lend itself towards a cast cylinder. There are other issues, as the Alamo also appears to use crankcase oil to partially cool the closed top of the sleeve above the top ring. The return oil passage passes thru the lower water inlet from the thermosyphon water cooling tank, which suggests this may require a pressurized oil supply to the sleeve.

A note of interest is that the 1KW Silent Alamo runs at whopping 2000 RPM, which is pretty durn fast for engines of this era.

Although this engine seems to be fairly simple, I really have to think this out more thoroughly before I start cutting any metal..

It also occurred to me that this timing concept should possibly work with a rotating disc in a cylinder head, but that would kind of take the fun out of it.

GUS