- Joined

- Apr 3, 2011

- Messages

- 192

- Reaction score

- 305

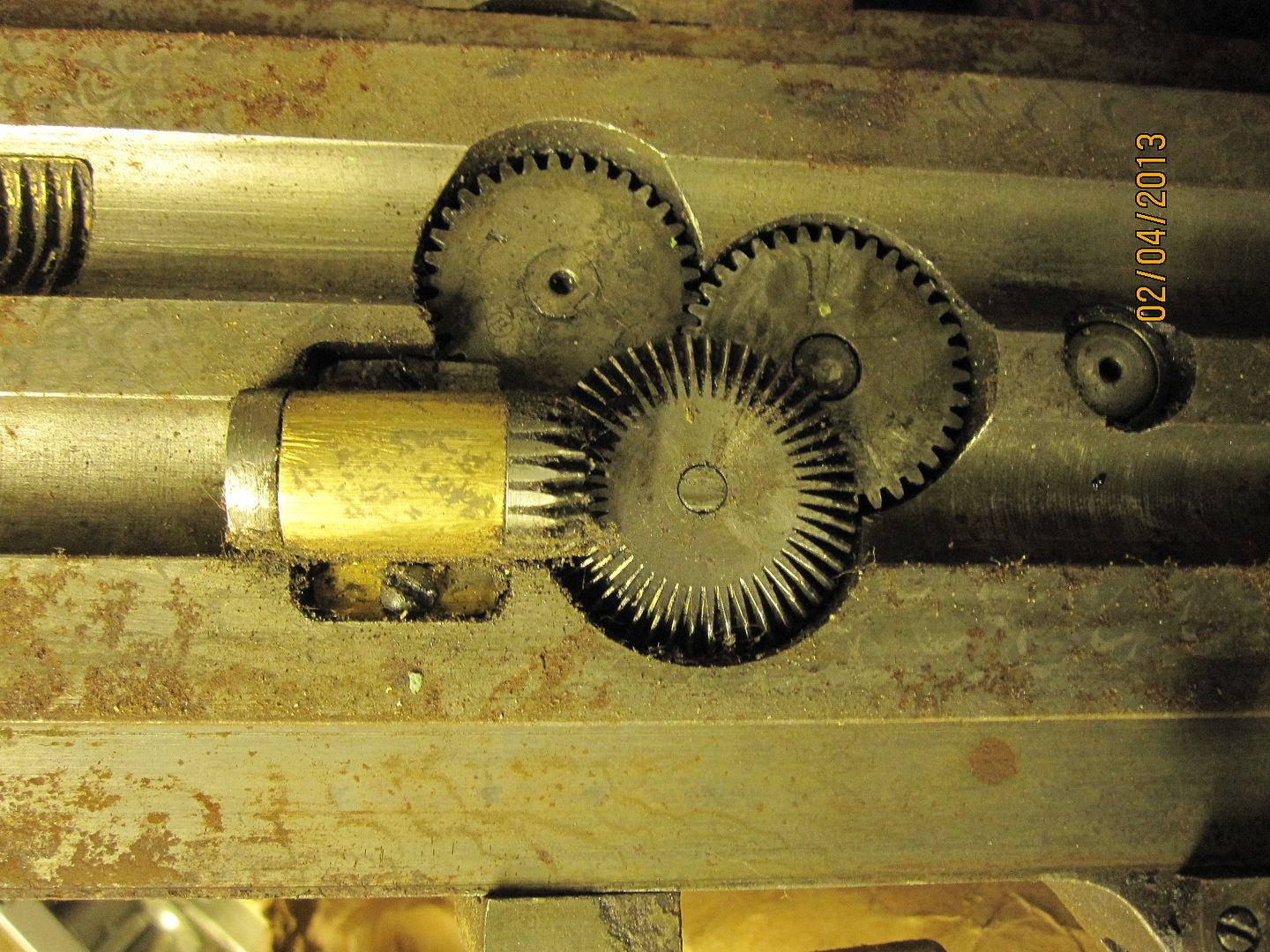

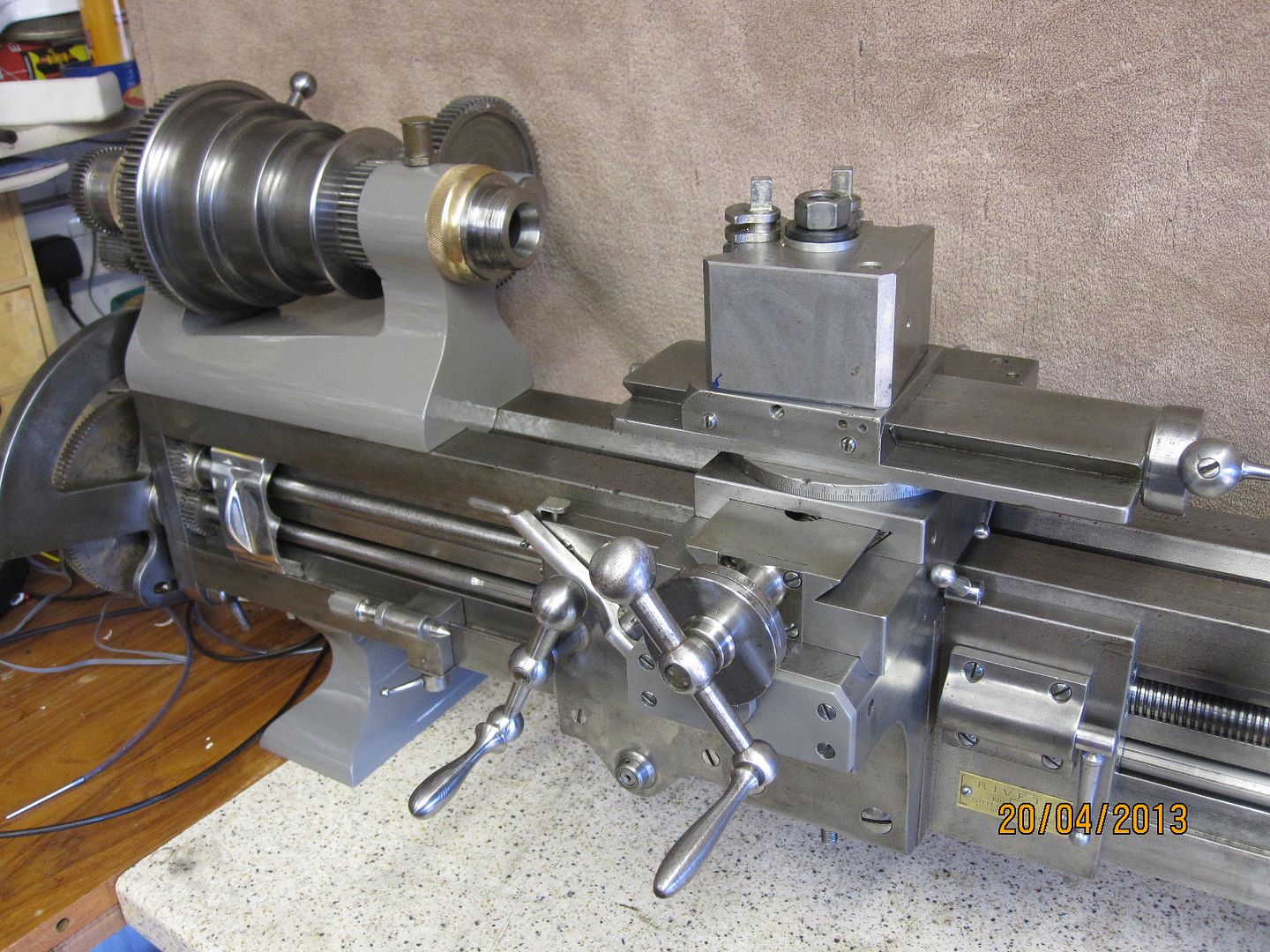

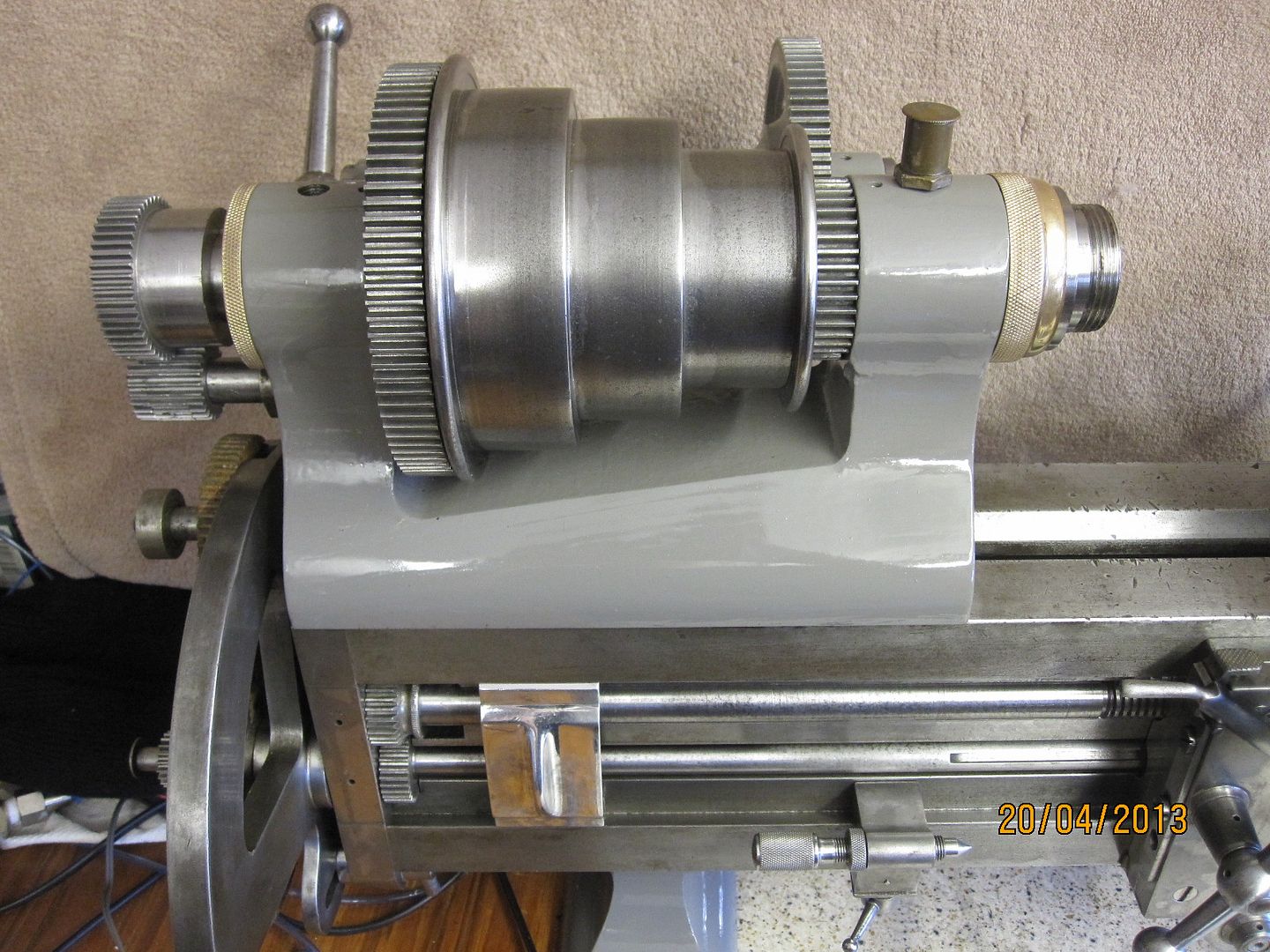

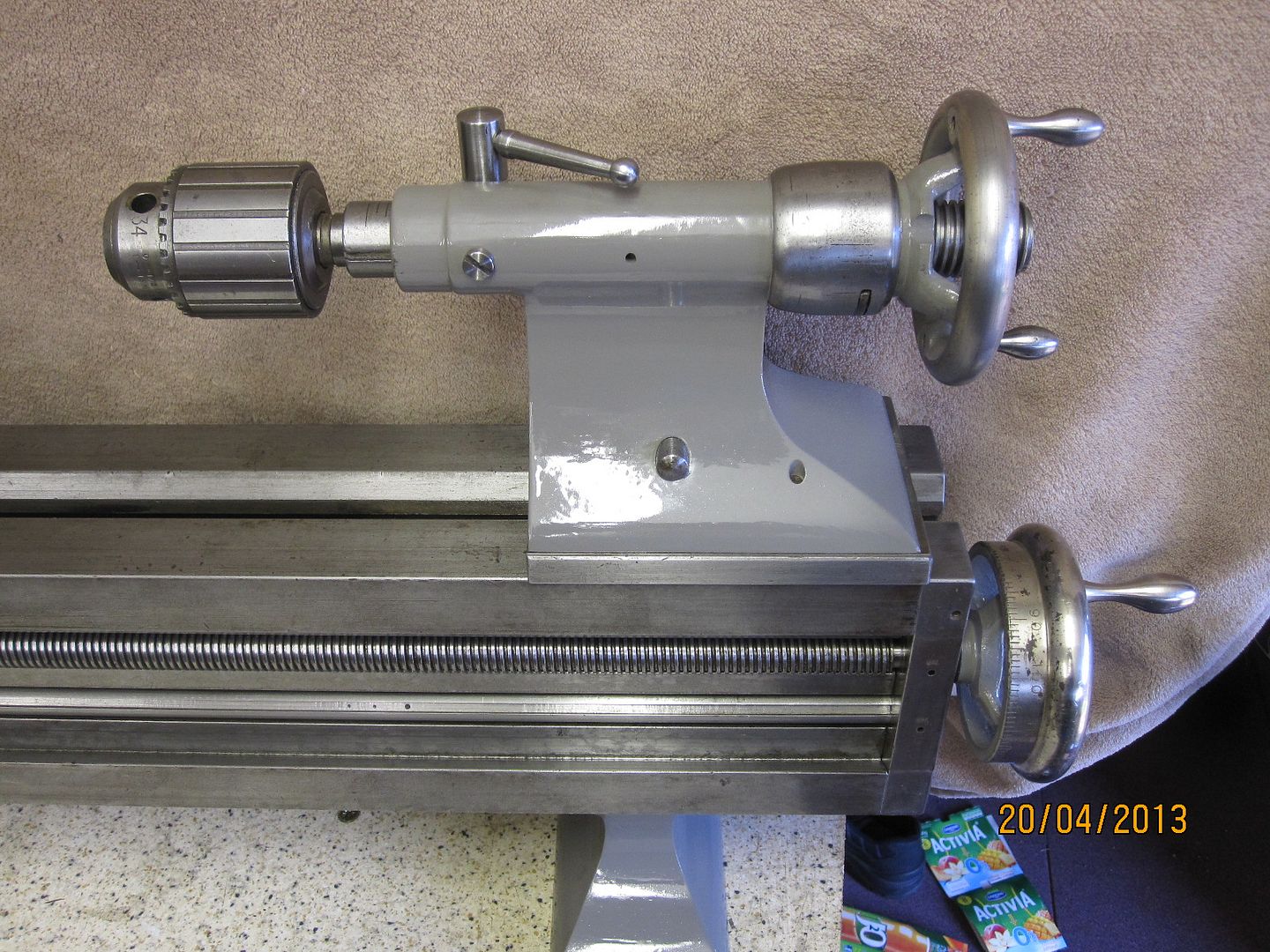

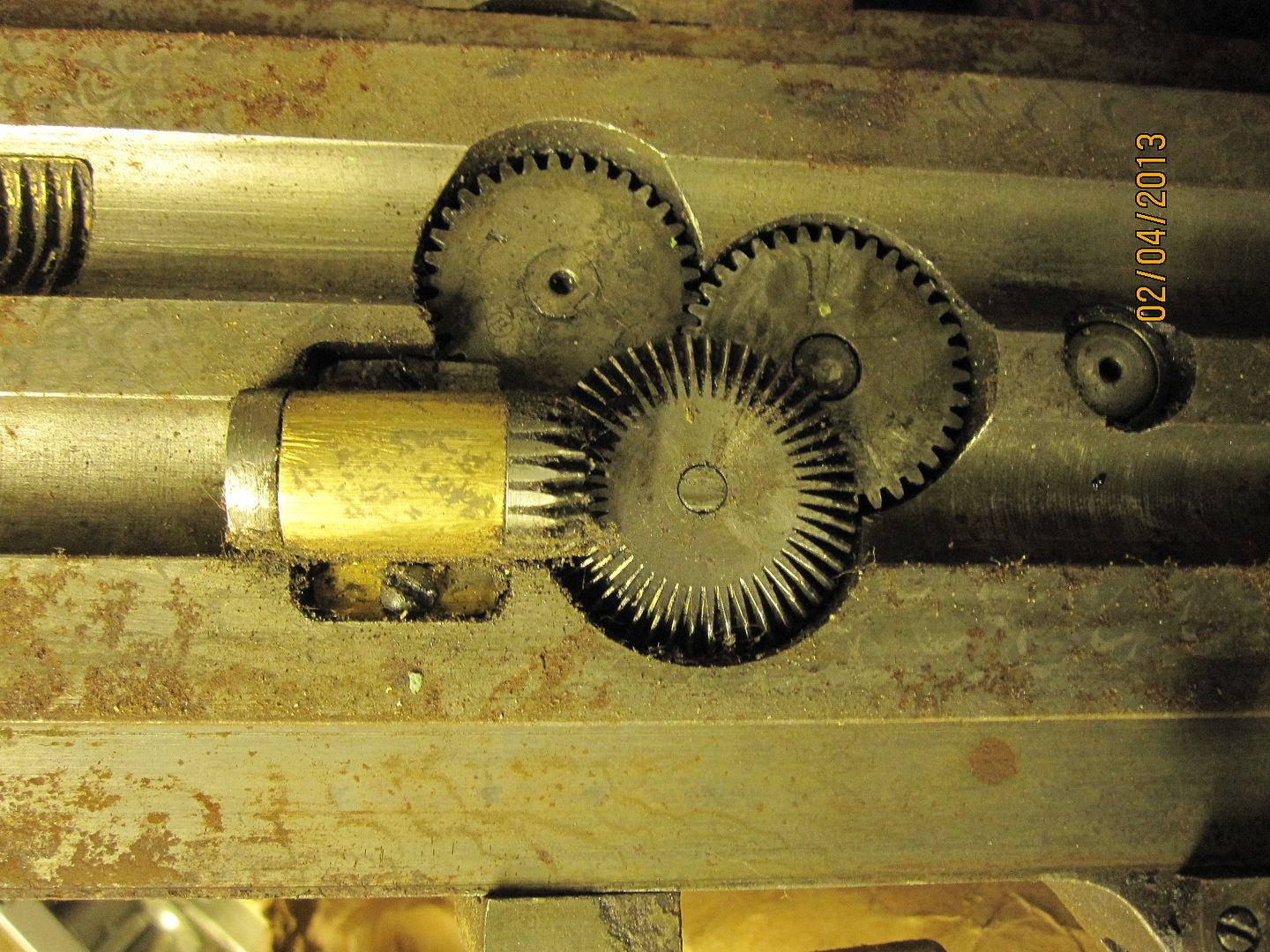

I've just aquired this Rivett lathe. I know a bit of it's history as I bought it as a basket case, about 25 years ago for a mate, but he's never done anything with it, and gave it to me today.

It was working when I bought it, but was stripped for delivery, and never touched since.

I can see 3 options....

Sell it as it is

Restore it and sell it, or

Restore it and use it.

I have room in the garage to set it up, if it's worth using.

So, I realise they are precision lathes, assuming it's not worn out, but it could also be worth some money too, ie. hundreds of pounds rather than 10's of pounds.

What would you do with it?

I'm in the UK.

Cheers, Keith.

It was working when I bought it, but was stripped for delivery, and never touched since.

I can see 3 options....

Sell it as it is

Restore it and sell it, or

Restore it and use it.

I have room in the garage to set it up, if it's worth using.

So, I realise they are precision lathes, assuming it's not worn out, but it could also be worth some money too, ie. hundreds of pounds rather than 10's of pounds.

What would you do with it?

I'm in the UK.

Cheers, Keith.