S

steamboat_bruce

Guest

Getting back to my original question, does anyone have experience in rolling 0.375" OD cupro-nickel tubes in brass tube sheets?

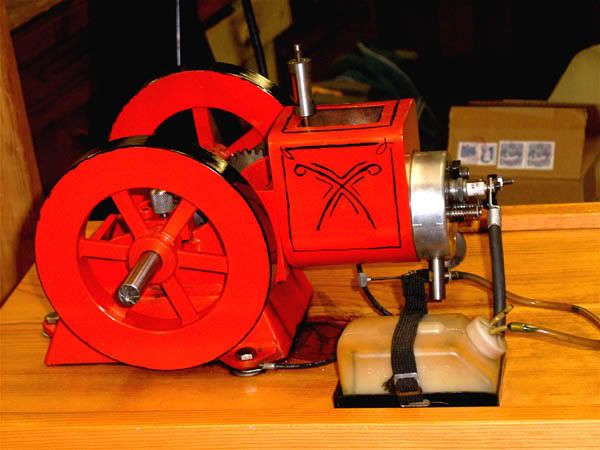

Jack said:Awhile back I started to make this little engine, it wasn't that difficult to build and it was made entirely out of the scrap box.

<embed width="448" height="361" type="application/x-shockwave-flash" wmode="transparent" src="http://i201.photobucket.com/player.swf?file=http://vid201.photobucket.com/albums/aa42/JackD_05/opencolumnenginerunning.flv"></embed>

Thanks for looking

:mrgreen:

Enter your email address to join: