el gringo

Well-Known Member

- Joined

- Aug 30, 2010

- Messages

- 333

- Reaction score

- 175

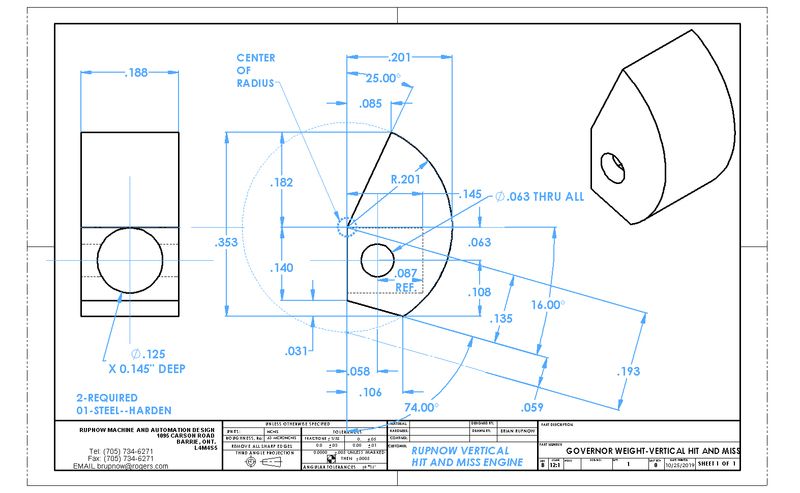

I was looking at the "weight" drawing and it is difficult for me to discern the actual lines of the part from the dimensional lines... is it possible to ask the computer to define the lines of one or the other on the drawing ?

Ray M

Ray M