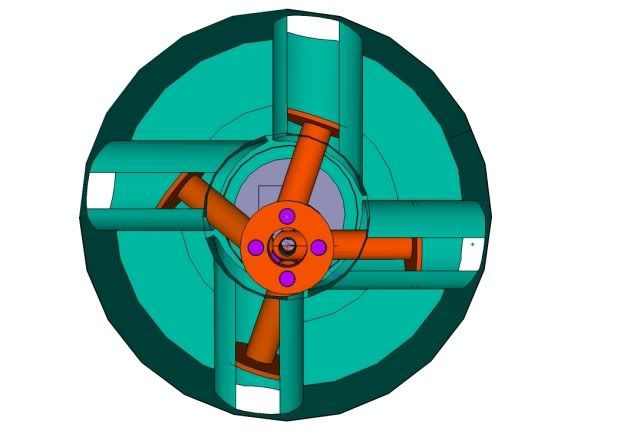

Someone queried a while ago as to a Double Rocker, so why not a Quad

Getting time to build something, so to aid in my trip to the nut house a Quad Rocker seems just the ticket for the ride. Havent a clue if the idea will even work but what the heck . . . Its a work in progress, making it up as I go along

The idea is roughly as shown, simple rotary Rocker type action.

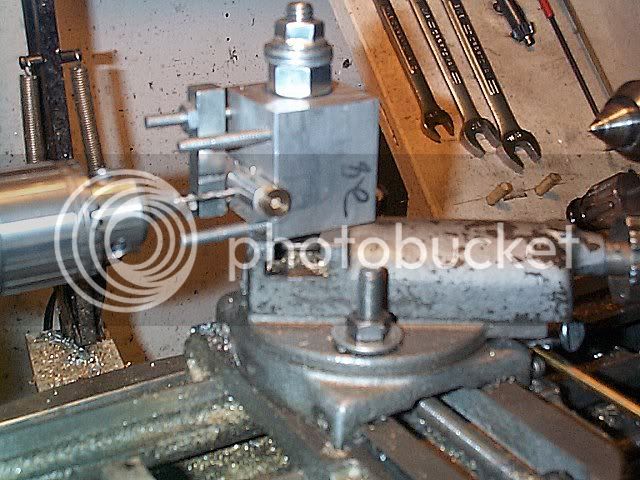

Found a piece of stock and carved out the main body. Drilling what will be the cylinders sorta taxed my brain cell till I came up with this contraption. Only have this ol AA109 so may look a tad odd.

Once the body was centered up on the little RT the side was found using a 0.250 edge finder. Cranked it over 1/2 the dia. of the body which just happened to be the spot for the cyl centerline as its to be 0.125 off center. Used a spot drill to mark the hole then drilled it up a tad under the final size of 0.375. Used a short 0.375 reamer to bring the bore to size. This done 4 times at 90 degree intervals.

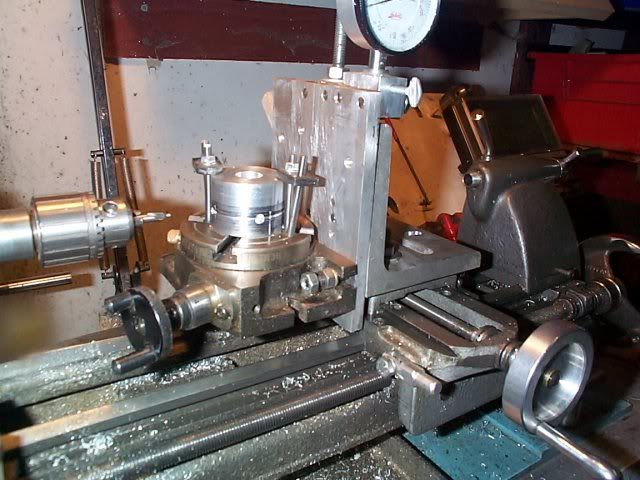

Time to work up a crankshaft and what will be the conecting rod pieces. I dont know how you all center things up, guessing the equiptment is better as I went round and round getting that piece of brass centered. Finally came to the point of tapping was moving it more than needed so resorted to just shimming one side a bit to get to a total runout of +\- 0.003. Best I could do.

Drilled the little holes that will be the crank pins. Why? What the heck its fun even if I'm clueless.

Shall see what tomorrow brings

Robert