- Joined

- Feb 17, 2008

- Messages

- 2,326

- Reaction score

- 440

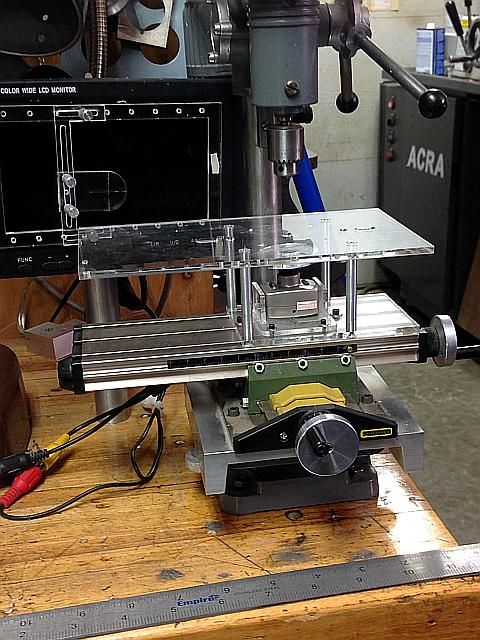

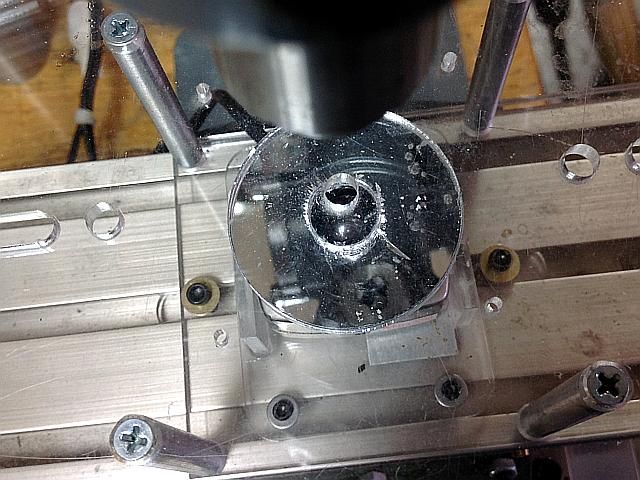

Years ago I could accurately drill a PCB at a rate of about 20 holes per minute. With decreased vision due to age and other things I no longer have any depth perception and found I could only do about 1 hole every 2 minutes and about a third of them were off center. So time for a fixture of sorts to fit my Cameron high speed drill press.

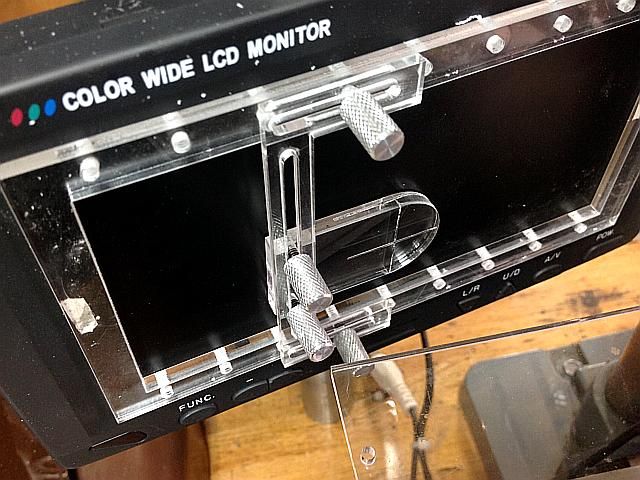

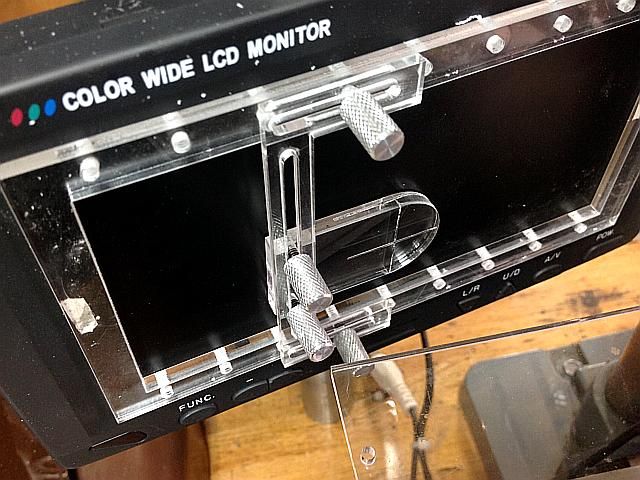

I started with a small closed circuit TV camera, about $9 dollars on ebay, and a 6 inch or so automotive backup TV monitor that I had on hand. The automotive monitor monitor works well as I could reverse the left/right and up/down directions to suit the camera orientation so the PCB moved in a natural direction on the screen.

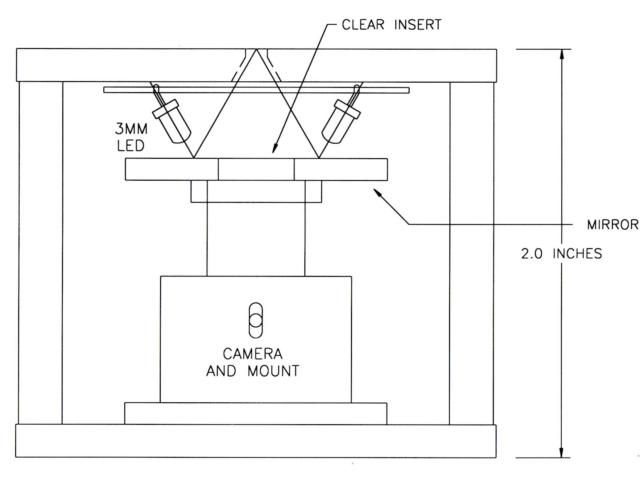

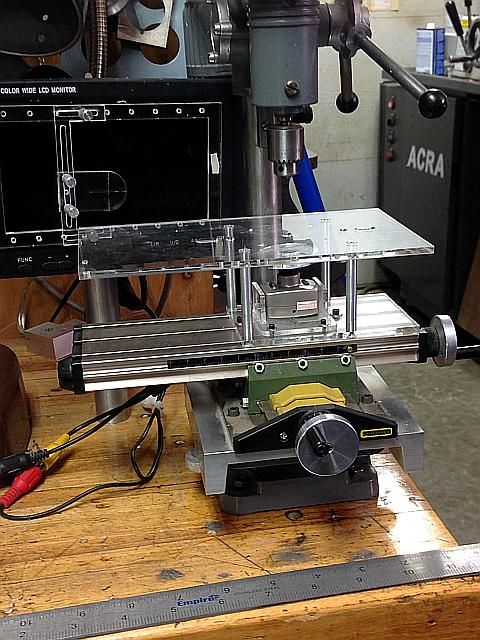

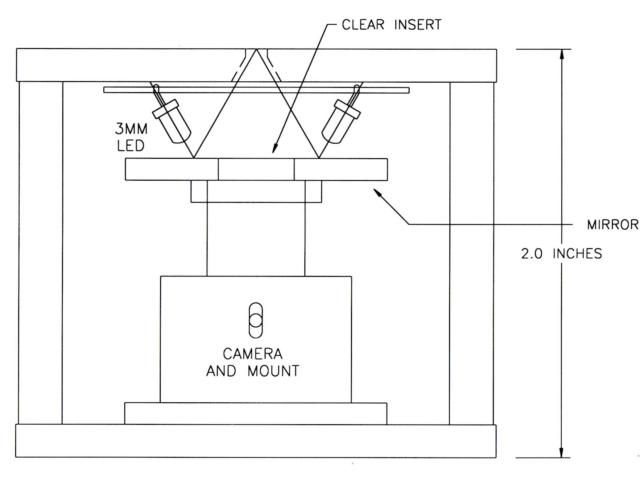

After a little bit of sketching I came up with something like this. The photos show the fixture with out the LED's as I found out that the ambient room light shining through the PCB gave better contrast with the translucent PCB. It's only a few minute job to install them if dealing with an opaque PCB.

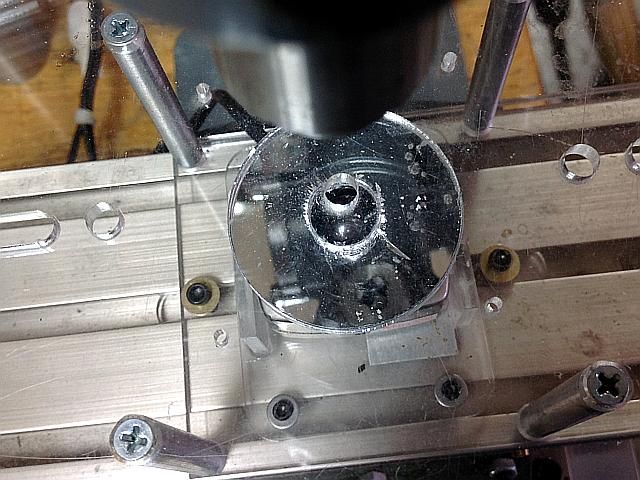

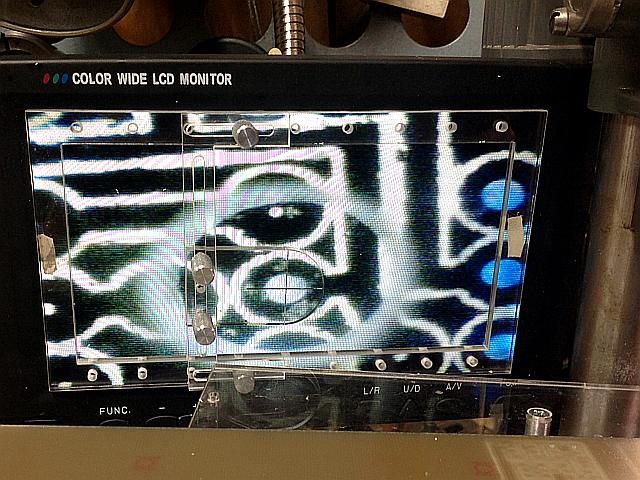

I have other cross hairs made up with white instead of black and a double cross hair with black lines in the vertical direction and white lines rotated at 45 degrees.

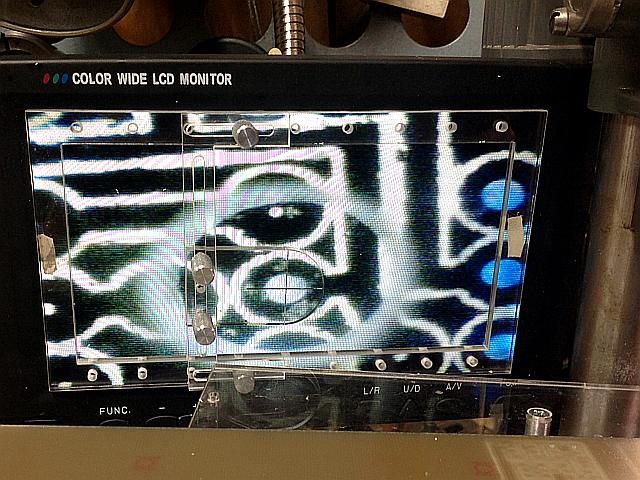

In operation. The cross hair is positioned over a hole just drilled and the next hole to be drilled is above it.

I started with a small closed circuit TV camera, about $9 dollars on ebay, and a 6 inch or so automotive backup TV monitor that I had on hand. The automotive monitor monitor works well as I could reverse the left/right and up/down directions to suit the camera orientation so the PCB moved in a natural direction on the screen.

After a little bit of sketching I came up with something like this. The photos show the fixture with out the LED's as I found out that the ambient room light shining through the PCB gave better contrast with the translucent PCB. It's only a few minute job to install them if dealing with an opaque PCB.

I have other cross hairs made up with white instead of black and a double cross hair with black lines in the vertical direction and white lines rotated at 45 degrees.

In operation. The cross hair is positioned over a hole just drilled and the next hole to be drilled is above it.