student_Machinist

Feist92

- Joined

- Jan 19, 2008

- Messages

- 86

- Reaction score

- 4

Hi guys

I started a poppin engine quite few months a go but got discouraged when thing didnt quite go my way (quite a common thing for me to do unfortunately, now i have plenty of half finished projects : )

)

But i figured it was about time that i got started on it again and tried to fix the problem.

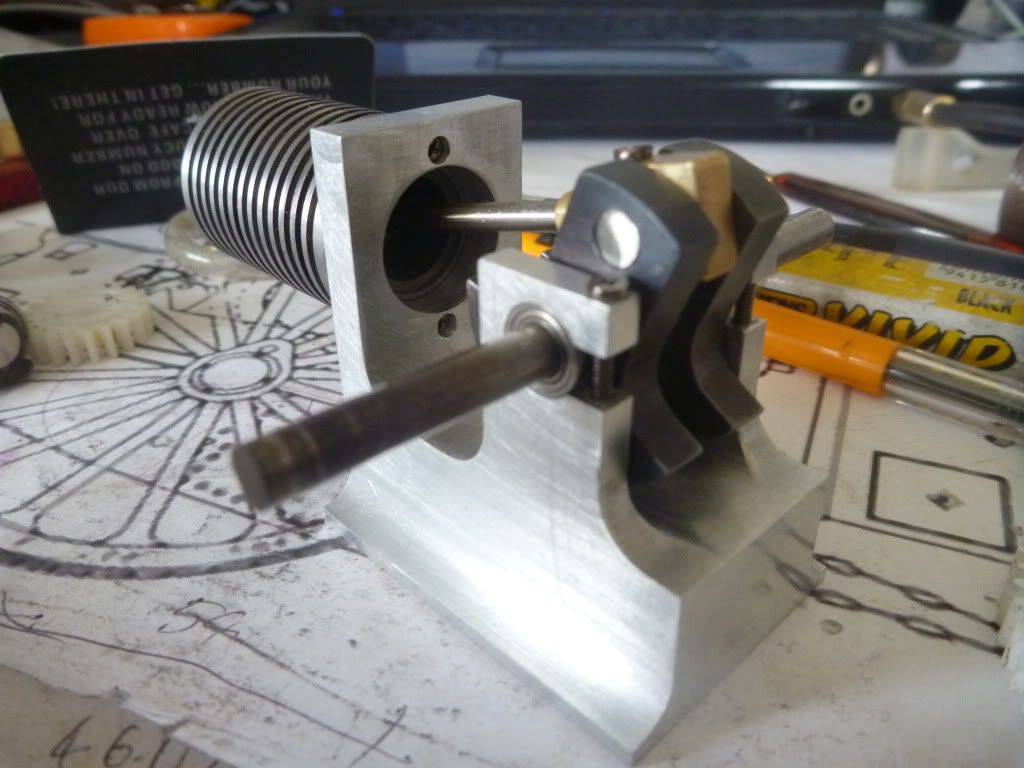

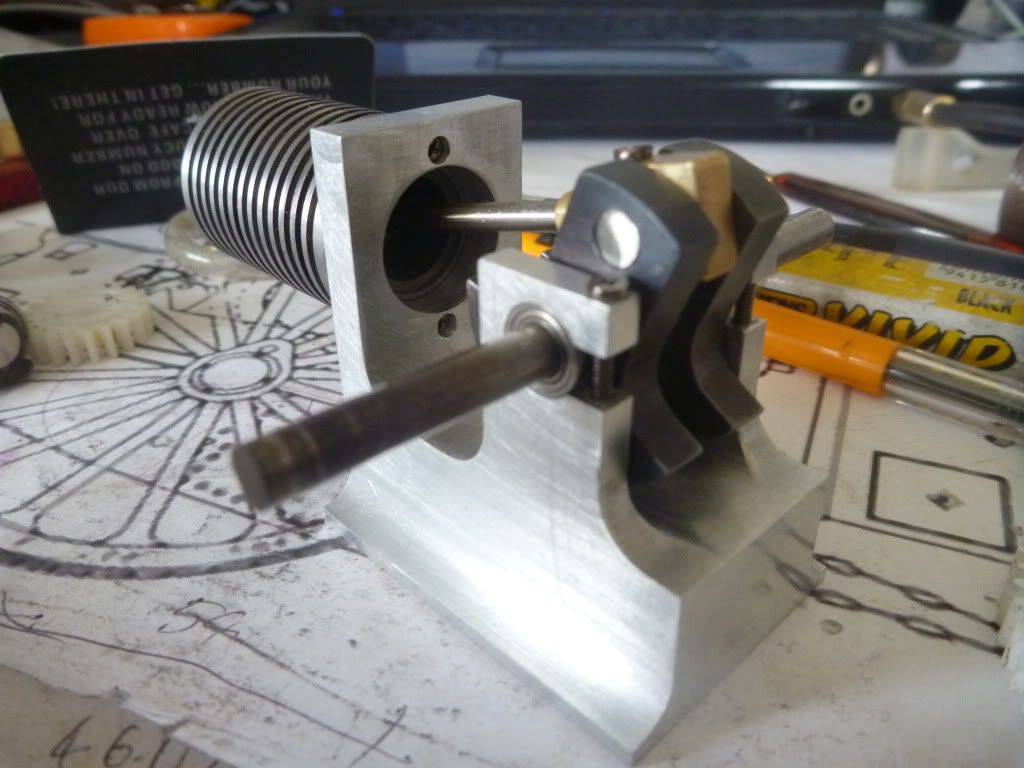

This is where im at at the moment

I need some suggestions with the piston and cylinder as no matter what i do it alway gets stuck.

When i clean it out with rubbing alcohol it has a really good almost frictionless airtight fit, but over night the piston gets stuck. i figure this was probably the piston/cylinder rusting so i then put some light oil in the cylinder and turned it over which freed it up. consequently after turning it over for a while the piston gets really stiff.

I dont seem to be able to win either way ???

any suggestions?

I started a poppin engine quite few months a go but got discouraged when thing didnt quite go my way (quite a common thing for me to do unfortunately, now i have plenty of half finished projects :

But i figured it was about time that i got started on it again and tried to fix the problem.

This is where im at at the moment

I need some suggestions with the piston and cylinder as no matter what i do it alway gets stuck.

When i clean it out with rubbing alcohol it has a really good almost frictionless airtight fit, but over night the piston gets stuck. i figure this was probably the piston/cylinder rusting so i then put some light oil in the cylinder and turned it over which freed it up. consequently after turning it over for a while the piston gets really stiff.

I dont seem to be able to win either way ???

any suggestions?