44-henry

Well-Known Member

- Joined

- Dec 5, 2008

- Messages

- 62

- Reaction score

- 22

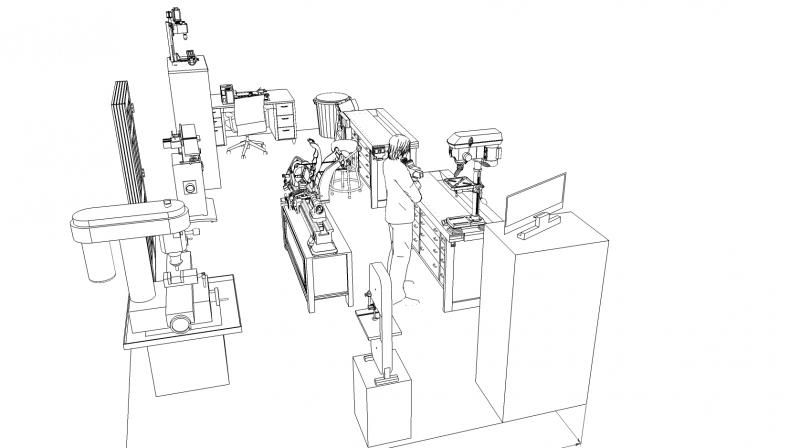

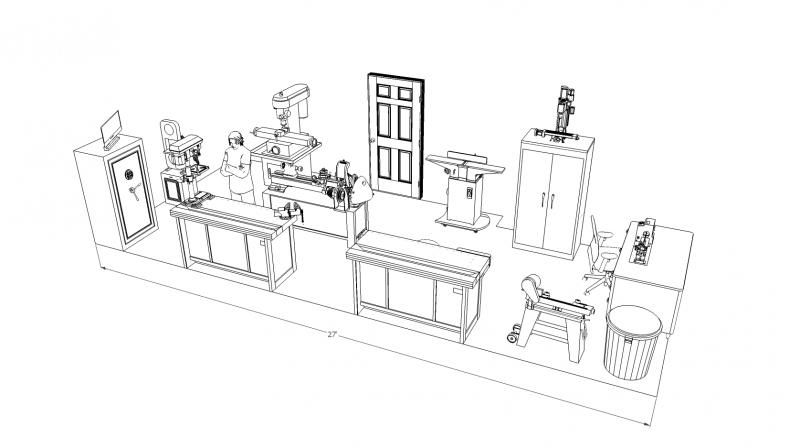

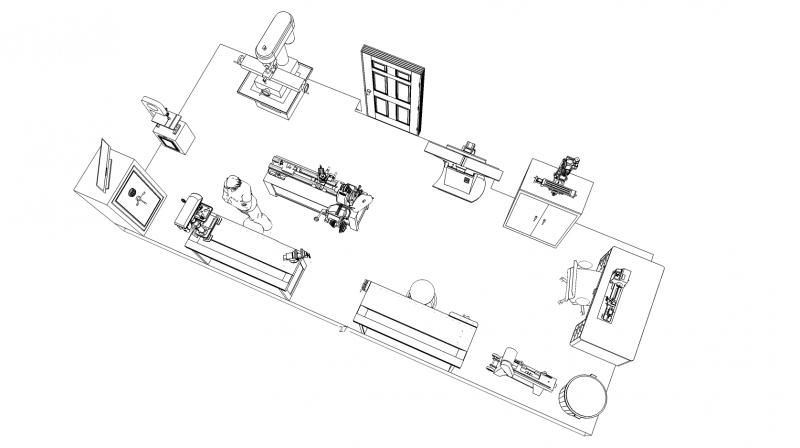

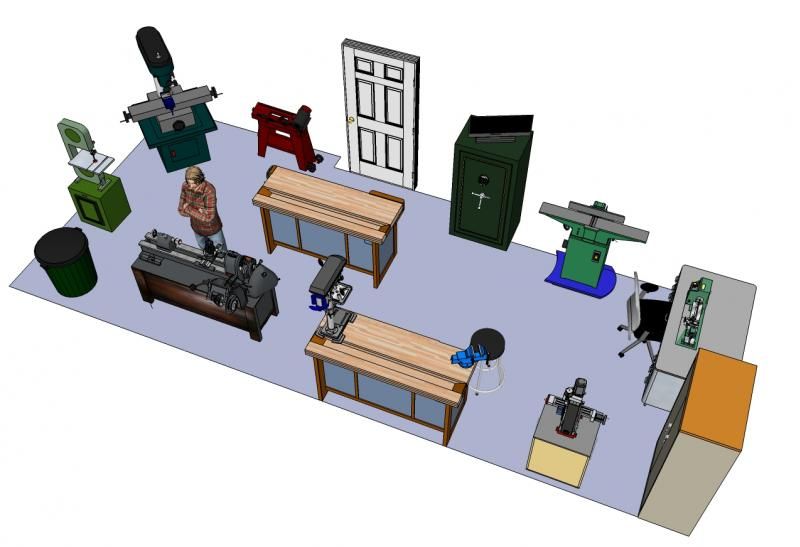

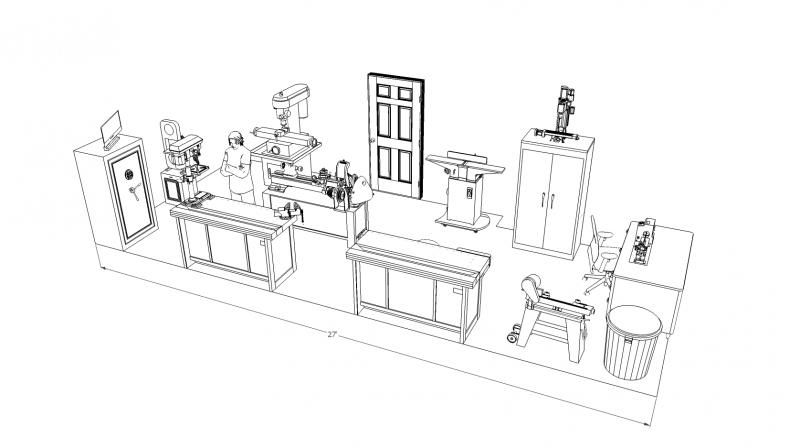

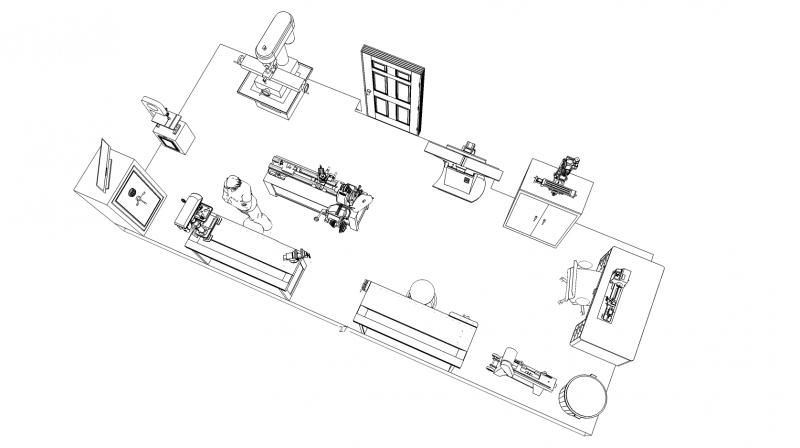

Last summer after remodeling our basement, my wife granted me access to the back portion of our basement giving me a workshop that roughly measures 27 x 12 feet. Though not huge, this is much better than the previous spare bedroom that I was working out of and finally gives me the room that I need to take some of my equipment out of storage.

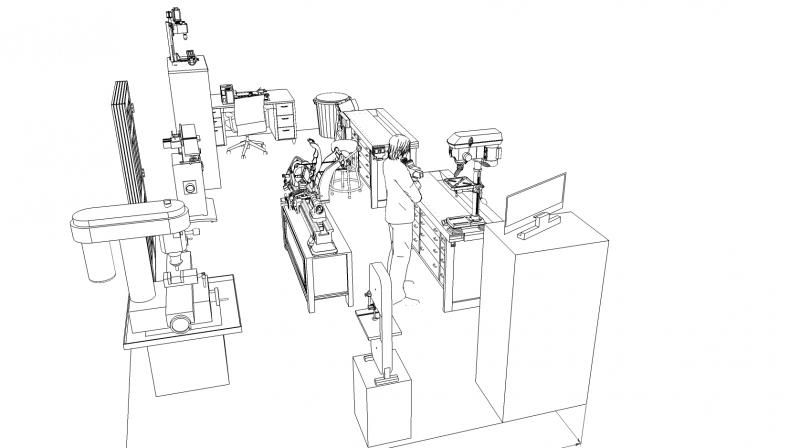

Though the process of building the area will take several months, I thought I would share the pre-stage where I have started the preliminary planning of the area using SketchUp software. Though I have used many different CAD programs in my career, I find the free SketchUp really useful for doing this sort of thing and the 3D warehouse that you can find free models to add to your drawings really cuts down on the time necessary to model in equipment and furnishings. With this I basically found equipment that was close and than scaled if up to the actual size.

I find this approach really helps to plan wiring and check for clearance around equipment.

Though the process of building the area will take several months, I thought I would share the pre-stage where I have started the preliminary planning of the area using SketchUp software. Though I have used many different CAD programs in my career, I find the free SketchUp really useful for doing this sort of thing and the 3D warehouse that you can find free models to add to your drawings really cuts down on the time necessary to model in equipment and furnishings. With this I basically found equipment that was close and than scaled if up to the actual size.

I find this approach really helps to plan wiring and check for clearance around equipment.