Dom,

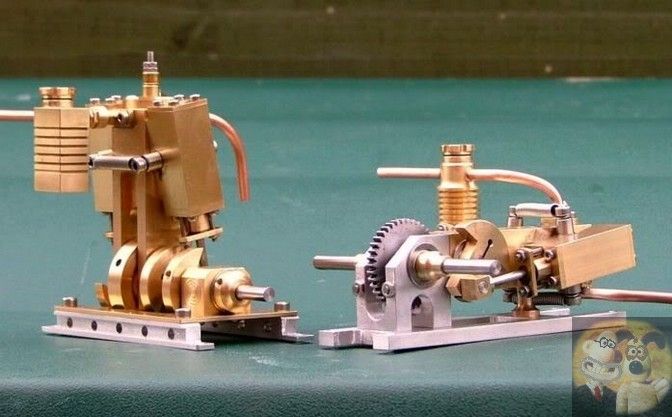

There are two main differences between piston valve and slide valve.

A piston valve is no more efficient than a normal oscillating engine, using the same principles for steam use and reversible by just swapping over the steam exhaust/inlet lines by use of a normal fwd/rev/speed valve. But a slide valve does look nicer than an oscillator because of the eccentric system rather than wobbling cylinders.

If I was going to use an engine in say a model boat, I would choose an oscillator any day, less messing about and super reliable, less things to go wrong. Just requiring one servo to control fwd/rev and speed.

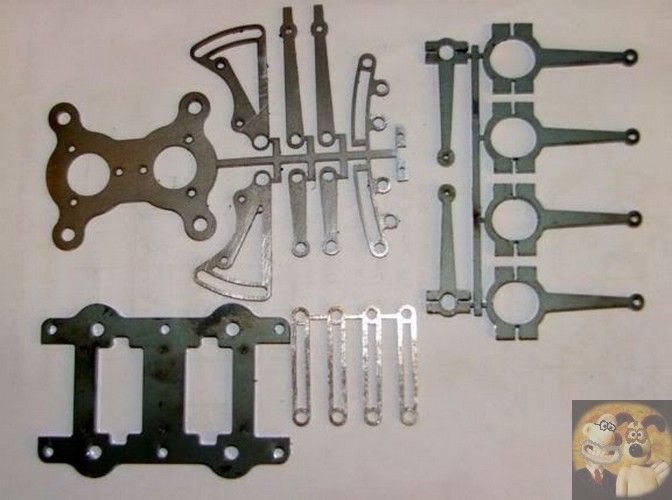

A slide valve is usually more steam efficient, especially if more than one cylinder and expansion cylinders are used, the down side is that it requires mechanical means to swap the eccentric timing to make it run in reverse.

If you want it to power something remotely, it would require two servos, one to control the reversing linkage and another to control the speed.

John

There are two main differences between piston valve and slide valve.

A piston valve is no more efficient than a normal oscillating engine, using the same principles for steam use and reversible by just swapping over the steam exhaust/inlet lines by use of a normal fwd/rev/speed valve. But a slide valve does look nicer than an oscillator because of the eccentric system rather than wobbling cylinders.

If I was going to use an engine in say a model boat, I would choose an oscillator any day, less messing about and super reliable, less things to go wrong. Just requiring one servo to control fwd/rev and speed.

A slide valve is usually more steam efficient, especially if more than one cylinder and expansion cylinders are used, the down side is that it requires mechanical means to swap the eccentric timing to make it run in reverse.

If you want it to power something remotely, it would require two servos, one to control the reversing linkage and another to control the speed.

John