Hello all.

I think the following analysis and quotes can make clearer the reasoning behind the PatWankel engine.

In the conventional Wankel Rotary the flame sees way bigger surfaces (and has to travel along way longer distances) than in a conventional engine.

The surface to volume ratio during combustion, only partly explains the increased thermal loss and the emissions of the Wankel.

The high surface to volume ratio is one only of the issues of the conventional Wankel.

According the “Liquid Piston” at

www.liquidpiston.com, their non-Wankel engine

runs closer to a constant volume combustion than the reciprocating piston engines.

Last year

DARPA signed a $1M agreement with Liquid Piston.

Take the five “cylinder” PatWankel shown in the drawings / animation.

At TDC (i.e. wherein the volume of the working chamber is minimised) almost all the air / mixture entered into the working chamber is concentrated in a compact cavity (spherical or semi-spherical etc).

As compared with a Ducati Panigale 1299cc reciprocating piston engine running at the same revs with the revs of the inner body of the PatWankel, the PatWankel provides more than 40% additional time around the TDC (1.15*1.25=1.43)

The 15% longer dwell at the TDC comes from the harmonic (i.e. pure sinusoidal) variation of the combustion chamber volume:

the 1.25 comes from the 225 degrees required in order the chamber to go from its TDC to its BDC (wherein the volume is maximised):

There is plenty of time, lots of squeeze and a very short distance for the flame to travel, enabling the combustion to actually complete inside the compact cavity.

Most of the thermal loss happens during the combustion.

The thermal loss continuous during the expansion, however the rate of thermal loss during the combustion is way higher.

Compare it with the thermal loss in a Ducati Panigale 1299 wherein the flame, during the combustion, sweeps the inner surfaces of a wide (116mm diameter) short (about 5mm height) cylinder (like a coin) having abnormal bottom and top (valve pockets etc).

Reasonably, the thermal loss towards the walls during the combustion will be substantially more than in the above PatWankel.

So, there are reasons for lower thermal loss in the PatWankel, despite the bigger (than in a reciprocating piston over-square engine) area of its wall surfaces.

Quote from:

http://gasturbinespower.asmedigitalcollection.asme.org/article.aspx?articleid=2467298

“Abstract

The Wankel rotary engine offers a greater power density than piston engines, but higher fuel consumption and hydrocarbon emissions, in large part due to poor gas sealing. This paper presents a model for the deformable dynamics of the side seal, which completes a set of modeling tools for the comprehensive assessment of the gas leakage mechanisms in the rotary engine. It is shown that the main leakage mechanisms for the side seals are: (1) opening of the inner flank due to the contact with the trailing corner seal, (2) flow through the gap with the leading corner seal, (3) simultaneous opening of both inner and outer flanks due to body force at high speed, and (4) running face leakage due to nonconformability at high speed. The leakage mechanisms are qualitatively validated at low speed with observed oil patterns on the rotor from laser-induced fluorescence (LIF) experiments. Finally, the predicted total leakage area for all the gas seals ranges from 1.5 mm2/chamber at low speeds to 2 mm2/chamber at high speeds, which is in agreement with the previous experimental studies, and the three gas seal types (side seals, apex seals, and corner seals) each accounts for about 1/3 of the total leakage, with minor variation as a function of speed.”

End of Quote

According the above abstract / plot, the leakage is a major problem / issue of the Wankel rotary engines.

Each cylinder of the Panigale 1299 has a capacity of 650cc, i.e. as much as each chamber of the Wankel RX-8.

Take a drill and make one hole of 1.5mm diameter (1.77mm2 area) on each piston crown of the Ducati Panigale, to allow each combustion chamber to communicate, through the hole, with the crankcase.

No doubt, the Panigale can still work, however a significant amount of high pressure gas will escape reducing the efficiency (a lot of energy is consumed to compress the gas that leaks without giving back any energy) and worsening the emissions.

This is the way the conventional Wankel works till now.

The gaps around each combustion chamber have an equivalent total leakage area of 1.5mm2 at low revs, to 2mm2 at high revs.

Compare the leakage from the “running surfaces” with the rest leakage.

Quote from

http://energyresources.asmedigitalcollection.asme.org/article.aspx?articleid=2522107

“Numerical Investigation on the Effects of Flame Propagation in Rotary Engine Performance With Leakage and Different Recess Shapes Using Three-Dimensional Computational Fluid Dynamics”

ABSTRACT

This study was carried out with an objective to develop a 3D simulation methodology for rotary engine combustion study and to investigate the effect of recess shapes on flame travel within the rotating combustion chamber and its effects on engine performance. The relative location of spark plugs with respect to the combustion chamber has significant effect on flame travel, affecting the overall engine performance. The computations were carried out with three different recess shapes using iso-octane (C8H18) fuel, and flame front propagation was studied at different widths from spark location.

Initially, a detailed leakage study was carried out and the flow fields were compared with available experimental results. The results for first recess with compression ratio 9.1 showed that the flow and vortex formations were similar to that of actual model. The capability of the 3D model to predict the combustion reaction rate precisely as that of practical engine is presented with comparison to experimental results. This study showed that the flame propagation is dominant toward the leading apex of the rotor chamber, and the air/fuel mixture region in the engine midplane, between the

two spark plugs, has very low flame propagation compared to the region in the vicinity of spark. The air/fuel mixture in midplane toward the leading apex burns partially and most of the mixture toward the trailing apex is left unburnt. Recommendations have been made for optimal positioning of the spark plugs along the lateral axis of the engine. In the comparison study with different recess shapes, lesser cavity length corresponding to a higher compression ratio (CR) of 9.6 showed faster flame propagation toward leading side. Also, mass trapped in working chamber reduced and developed higher burn rate and peak pressure resulting in better fuel conversion efficiency.

Third recess with lesser CR showed reduced burn rates and lower peak pressure.

End of Quote.

It is more complicated than “surface to volume” ratio.

According the last plot, if the leakage is avoided, the same Wankel increases its power, reducing at the same time its brake specific fuel consumption (g/kWh).

The surface to volume area remains as high as before.

So, if we could reduce substantially the leakage in the conventional Wankel, an significant increase of the power output and a significant decrease of the BSFC are expected.

This is what the following PatWankel:

does: it reduces the gas leakage to levels met in the reciprocating piston engines.

If the plot of ASME is not wrong, the improvement (on the power output and on the mileage) on a Mazda RX-8 when modified to PatWankel would be significant.

But there is more.

The other version of the PatWankel (the PatWankel wherein the seals slide onto the surface of the inner body) besides reducing the leakage it performs another significant “task”: it enables a compact combustion chamber to be formed, wherein almost all the mixture is concentrated and is burnt before the expansion.

This improvement may prove in practice more important than the significant reduction of the gas leakage.

The mechanical friction in a rotary engine like the PatWankel 5-cylinder is substantially lower than in an “equivalent” reciprocating piston engine.

There is no valve train.

There are no piston skirts to thrust on cylinder walls.

The four roller bearings on the frame and the sliding of the seals on the working surface are the only cause of mechanical friction.

All the energy / torque passes directly through the shaft of the inner body to the load.

The outer body receives no torque, at all.

[FONT="]If you count all these together (improved sealing, fast combustion into a compact cavity, reduced mechanical friction, simplicity etc) things get more than interesting.

[/FONT]

The following animation may-be useful for timing-check reasons:

The angle step is 10 degrees (as in the conventional engine, 180 degrees separate the TDC (wherein the volume of a working chamber is minimized) to BDC (wherein the volume of the same working chamber is maximized).

Start counting “frames” (and degrees) the moment the inner body is “horizontal” with the ports at right.

The timing shown is conservative.

The “overlap” may seem big, but it is quite small. This is so because during the “overlap” either the intake ports, or the exhaust ports, or both, are almost closed by the inner surface of the outer body.

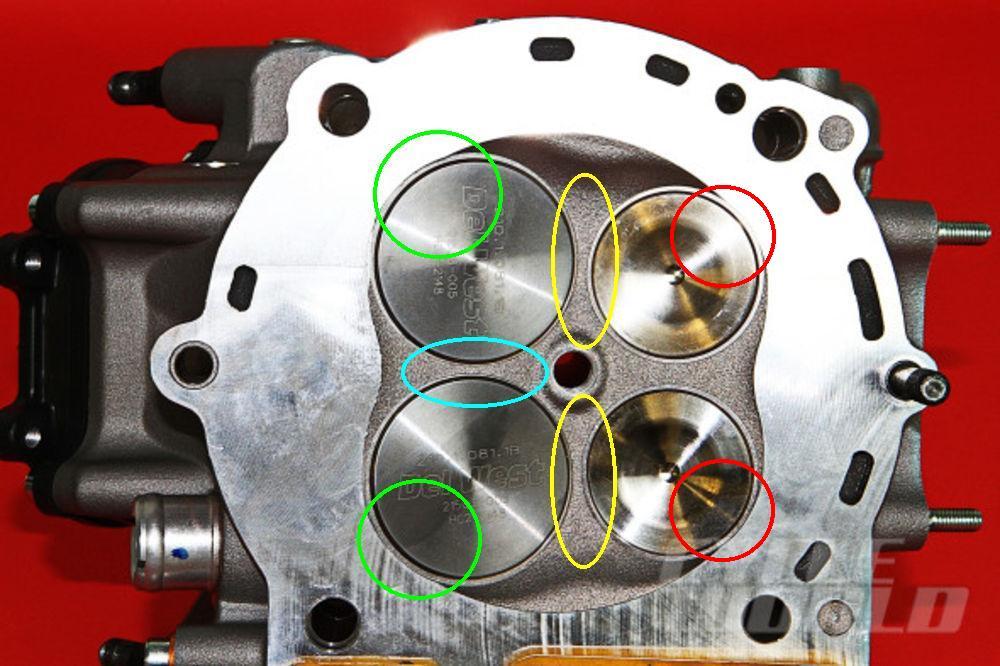

The overlap in this engine is way different than in a, say, Ducati Panigale:

wherein overlap means, more or less, the “short circuit” between the intake and the exhaust (the area marked by the yellow ellipses) and inevitable loss of unburned mixture,

while in the above PatWankel overlap means a through or uniflow “scavenging” of the chamber by the fresh charge (more or less as in the opposed piston engines) that sweeps / pushes out the burned gas and reducing this way the residual gas.

By the way:

Last month LiquiddPiston received another $2.5 million from

DARPA for their rotary engine.

More important: LiquidPiston also received a $25,000 cash prize from

Shikorsky along with the opportunity to explore opportunities for LiquidPiston's technology with the Shikorsky product line

Thanks

Manolis Pattakos