chucketn

Senior Citizen

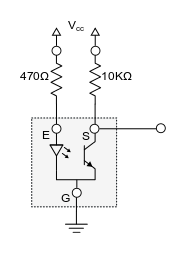

I have a small DC motor that was removed from an old Lexmark Laser Printer Tray. The motor has what looks like a optical or IR emitter/detector under a plastic cover on one end. The motor has a disk on the shaft with small holes in it which is positioned so that the Emitter/detector straddles it.

I want to hack the circuit for the emitter/detector, but it is not marked to identify it. How do I figure out it's properties and circuit requirements?

It has 3 wires, and I have used a multimeter To measure resistance between the leads.

Once I figure out the electrical characteristics I want to use an Arduino Uno to experiment with it.

Chuck

I want to hack the circuit for the emitter/detector, but it is not marked to identify it. How do I figure out it's properties and circuit requirements?

It has 3 wires, and I have used a multimeter To measure resistance between the leads.

Once I figure out the electrical characteristics I want to use an Arduino Uno to experiment with it.

Chuck