Hi Everyone

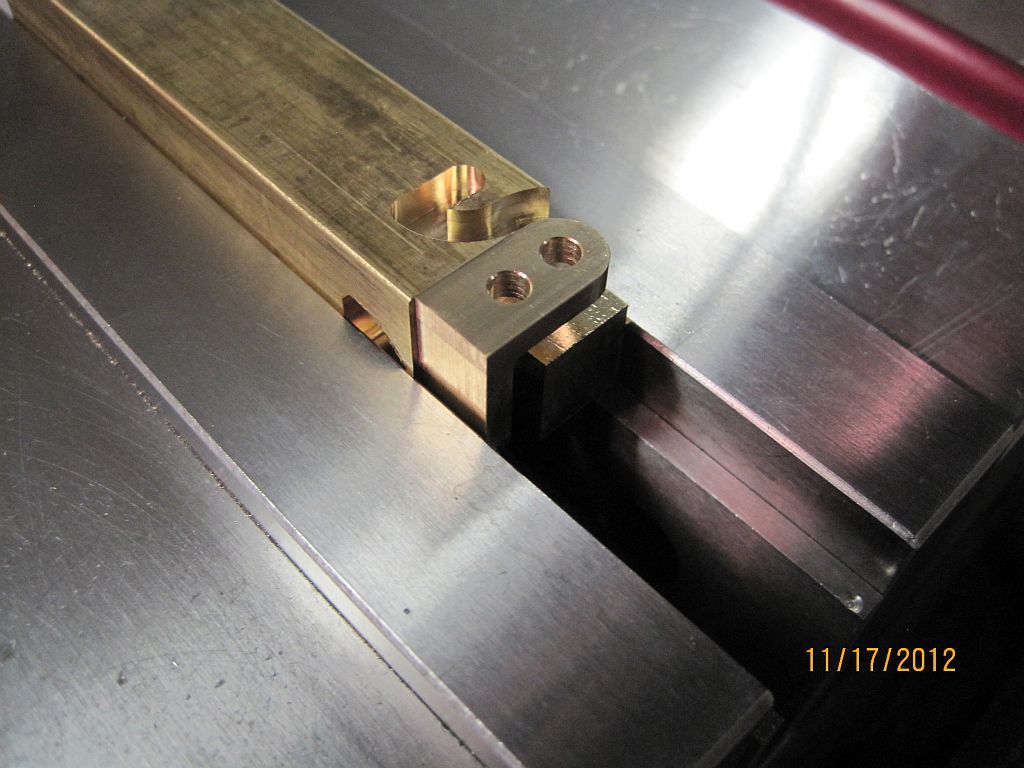

Im still working on exhaust valve related stuff; here are a group of pictures showing the machining of the swing arm. The swing arm holds the crossover cam follower shoe and the valve lifter. It is suspended between the upper and lower supports and pivots on setscrews with a 60° point.

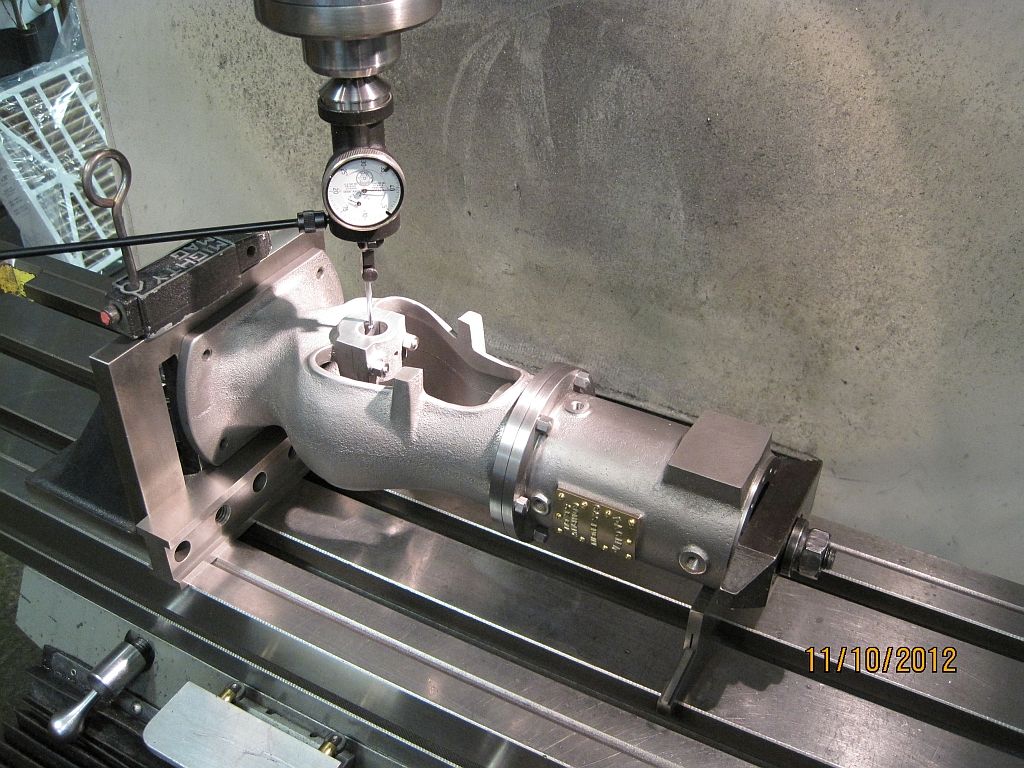

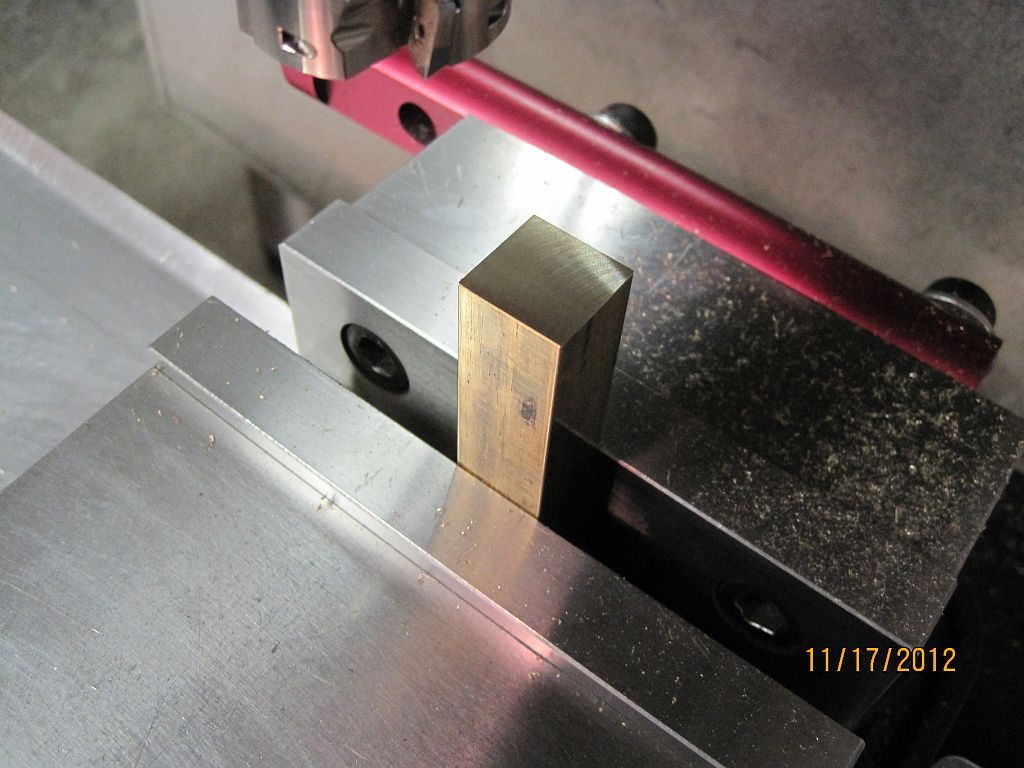

I figured that the easiest way to hang onto this casting would be to make a fixture that allowed all machining operations to be done in one set up.

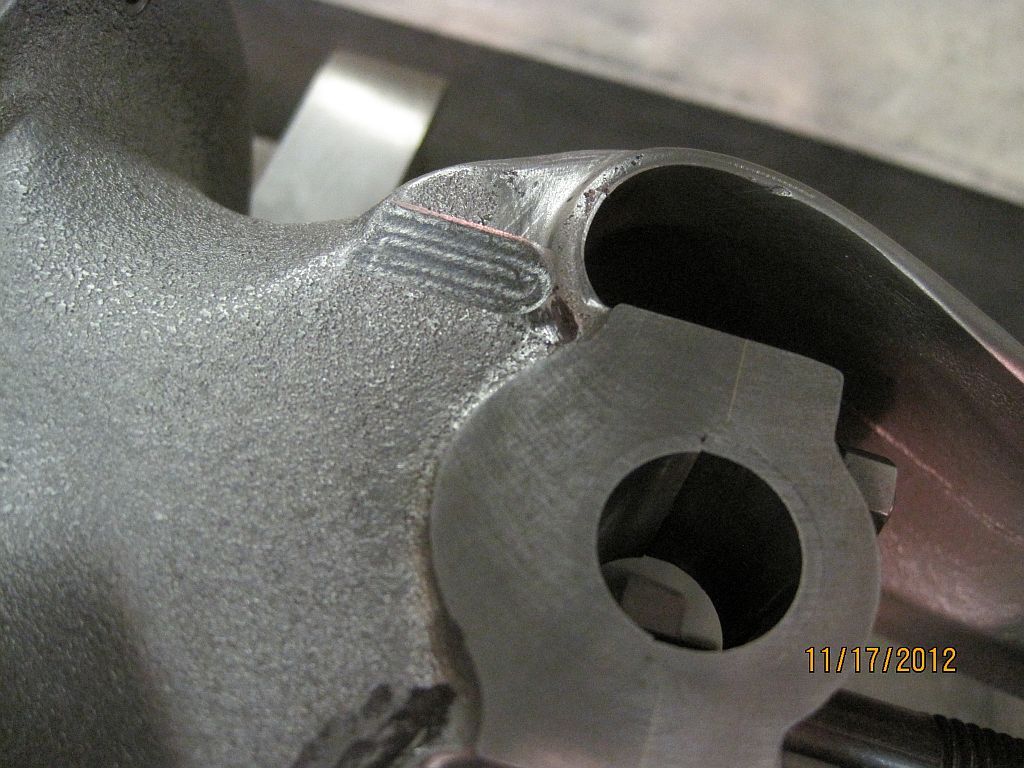

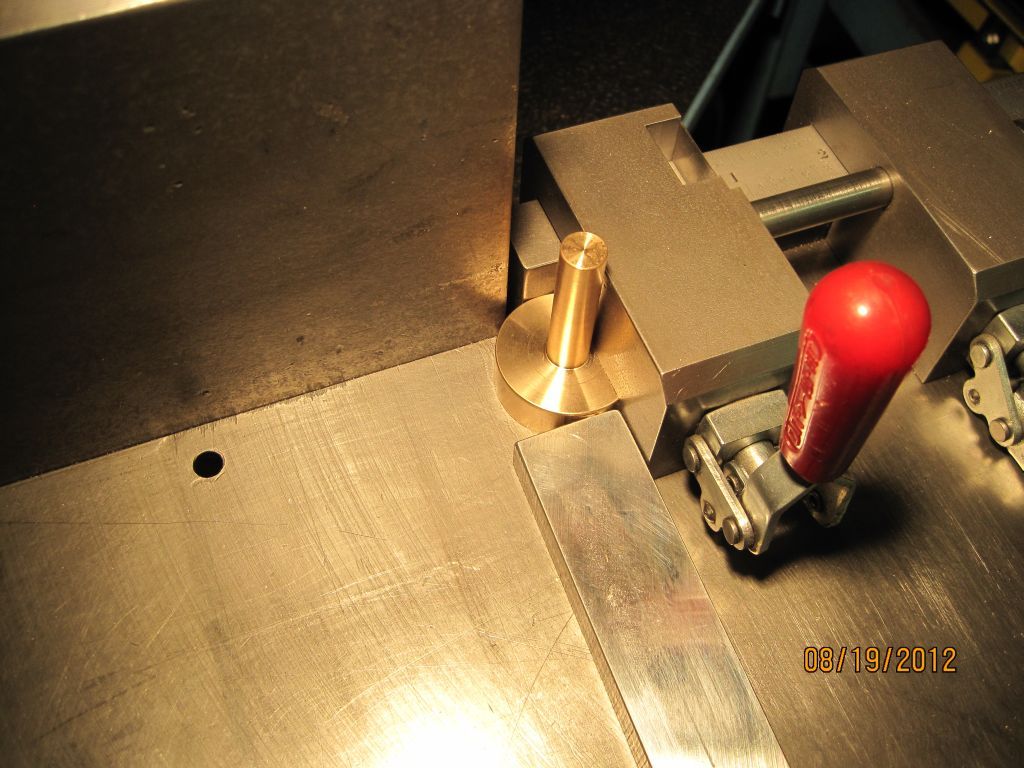

Here is the raw casting for the swing arm.

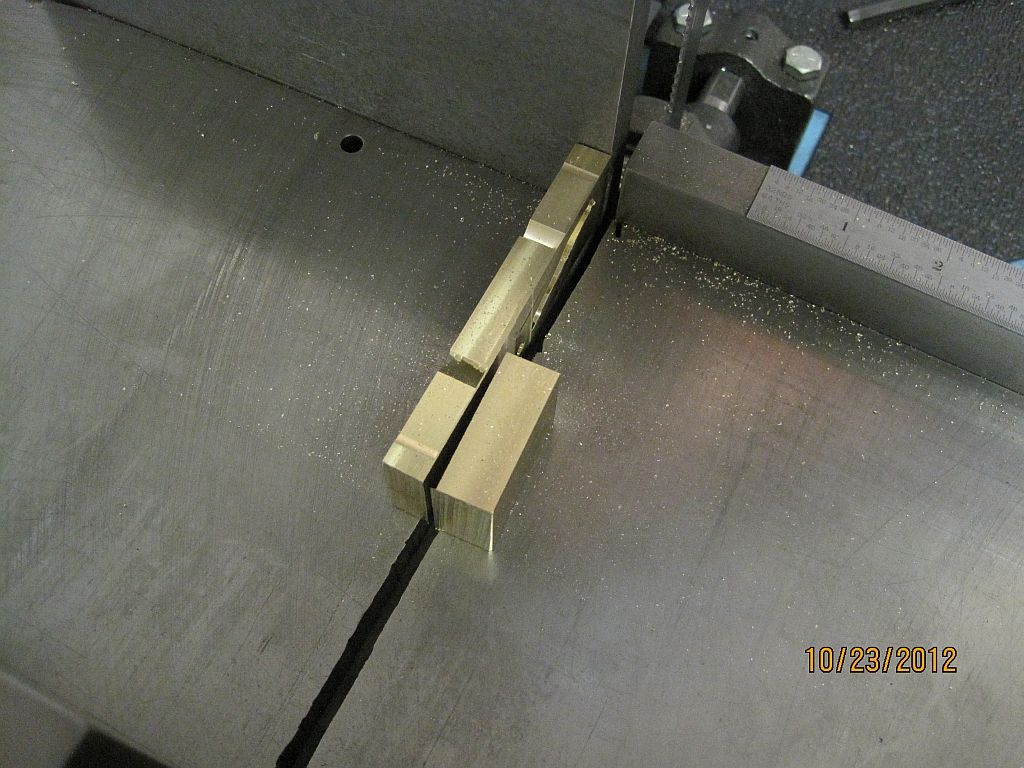

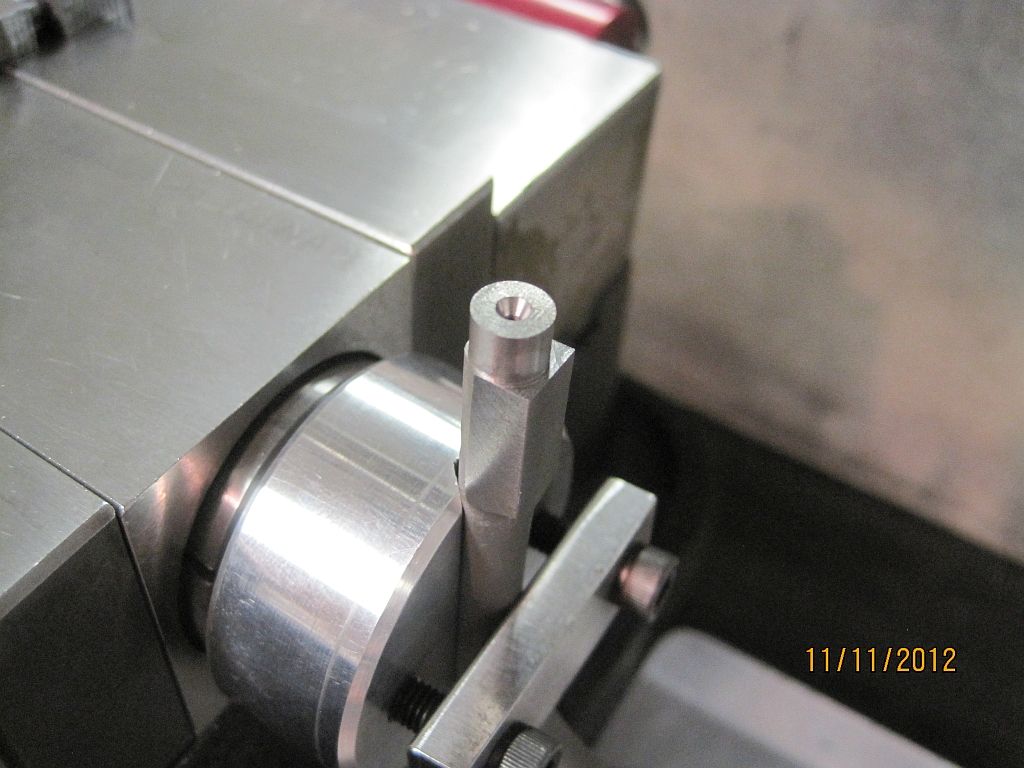

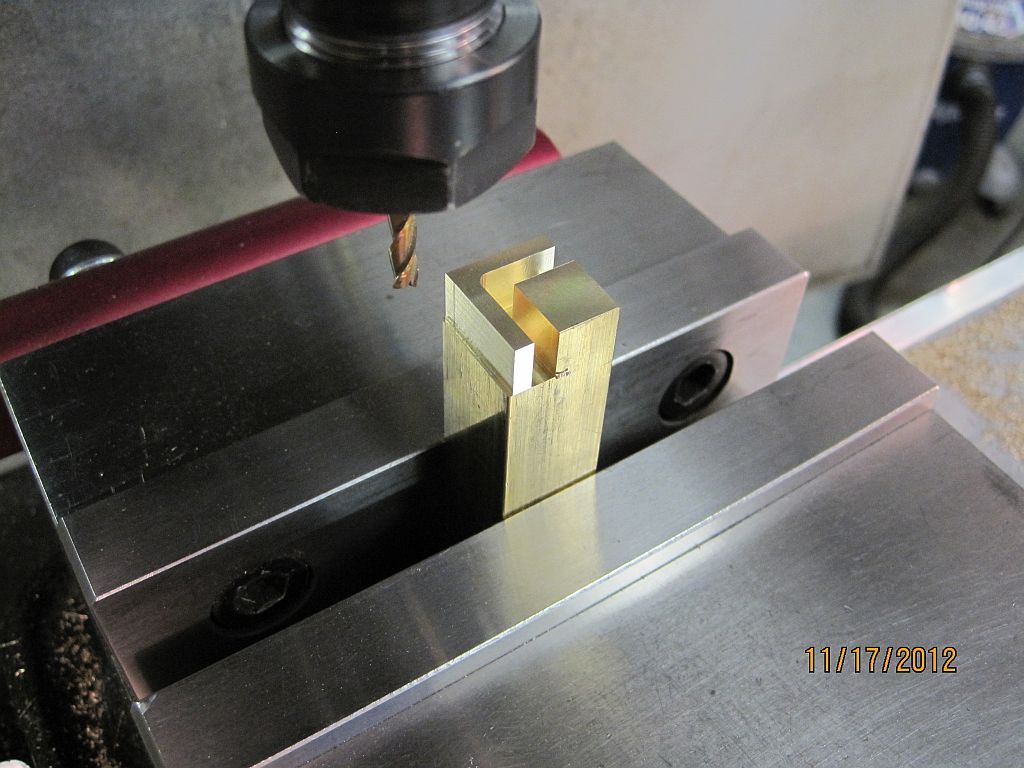

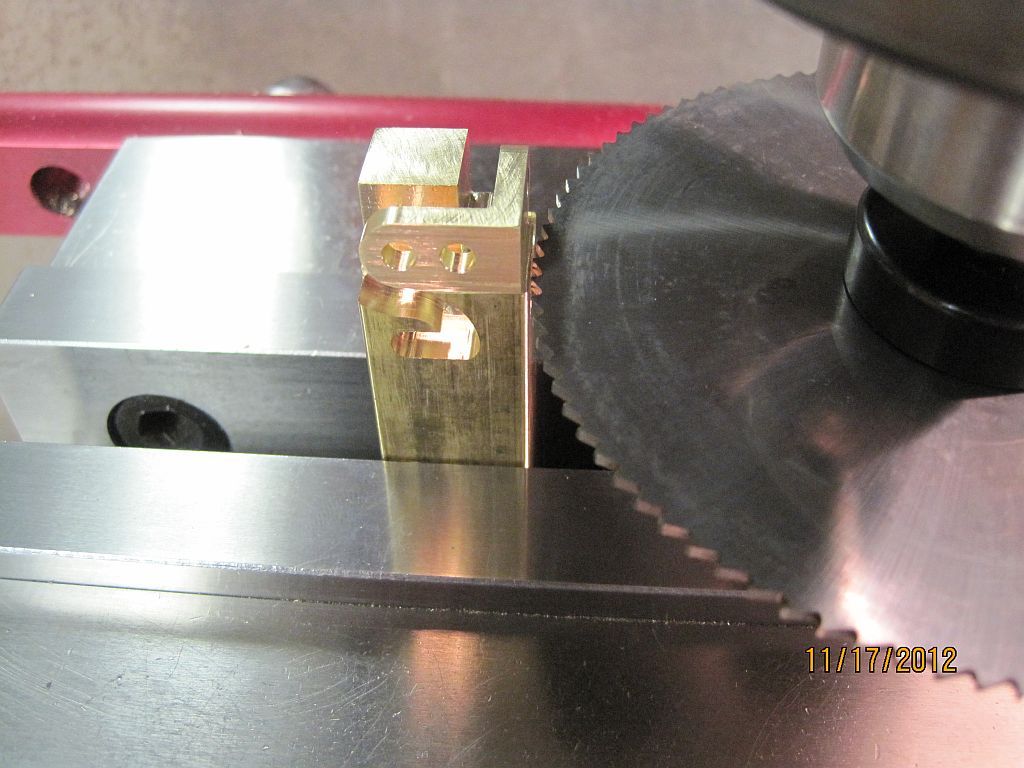

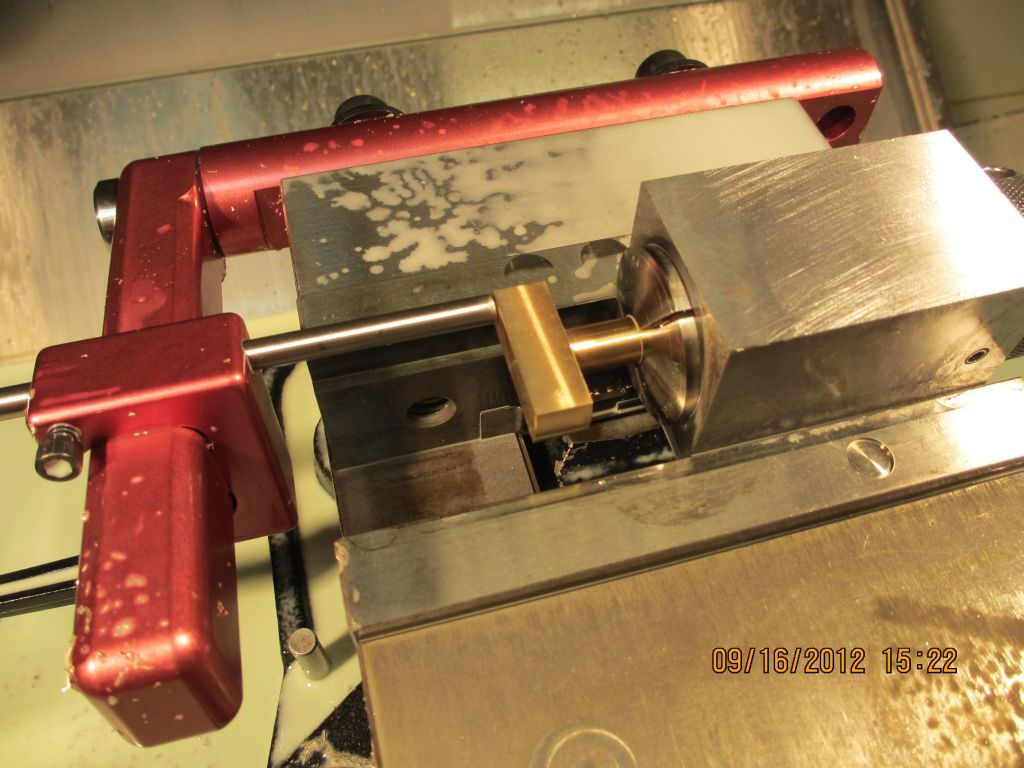

The fixture is a button V block and strap clamp indexed in a square collet block.

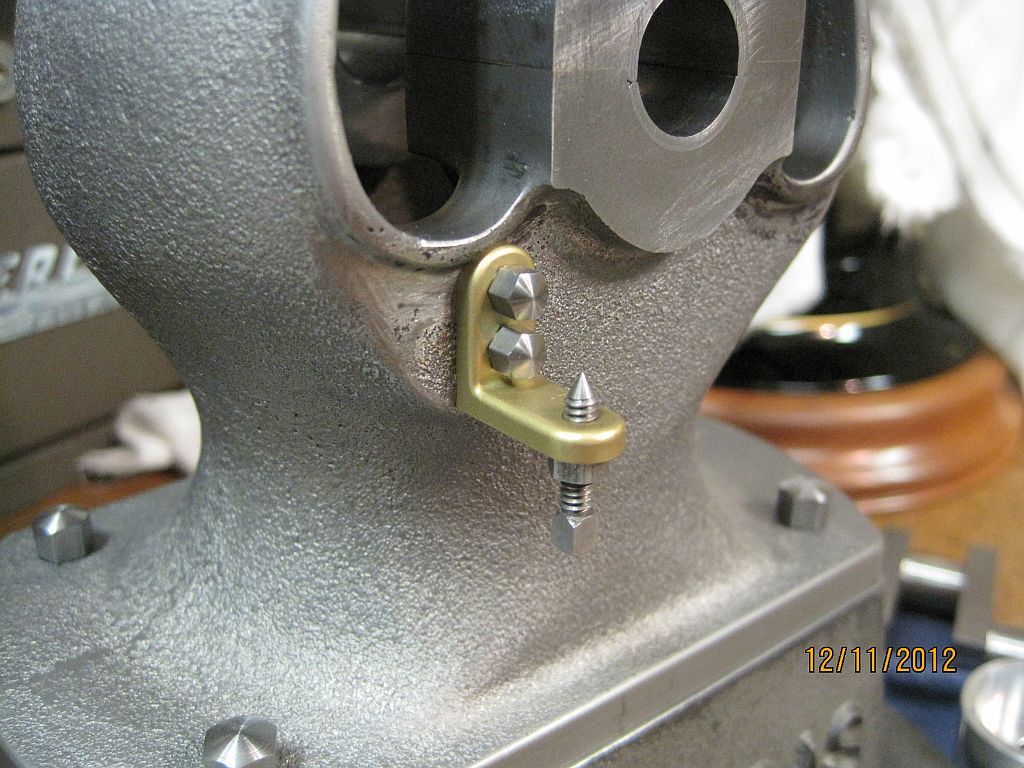

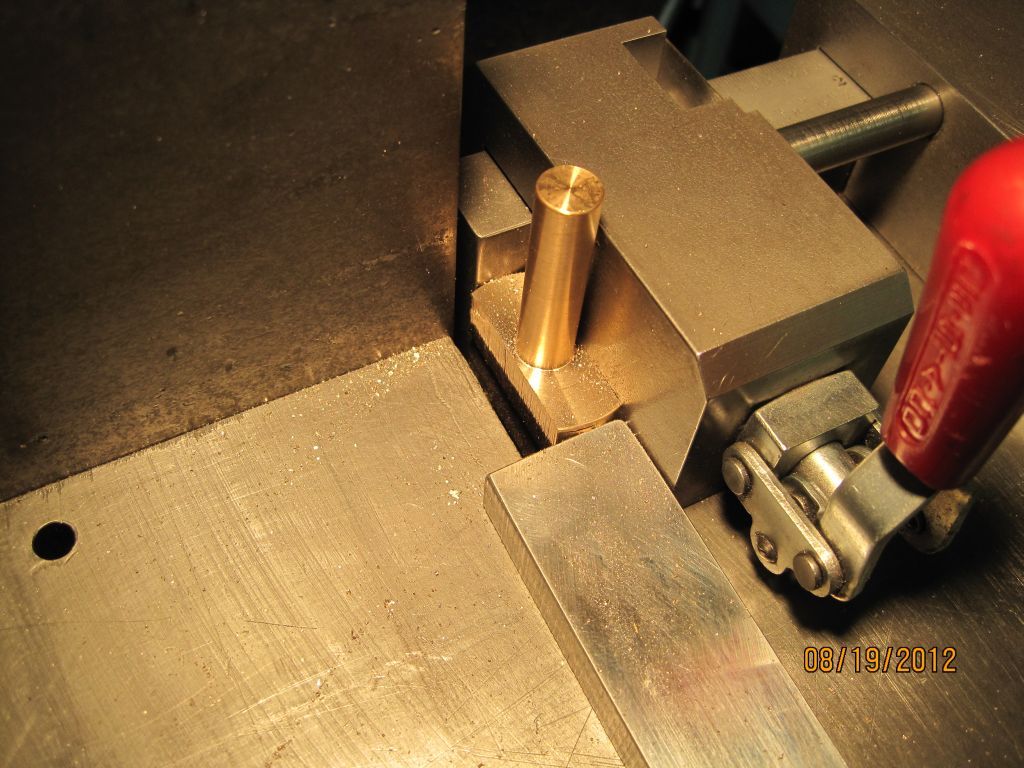

Here is the swing arm casting mounted in the fixture. The fixture was set on the surface plate and the follower shoe pivot housing was indicated to be in the same plane as the center line of the V. this was accomplished by flipping the block over and adjusting the position until the same indicator reading was obtained both ways.

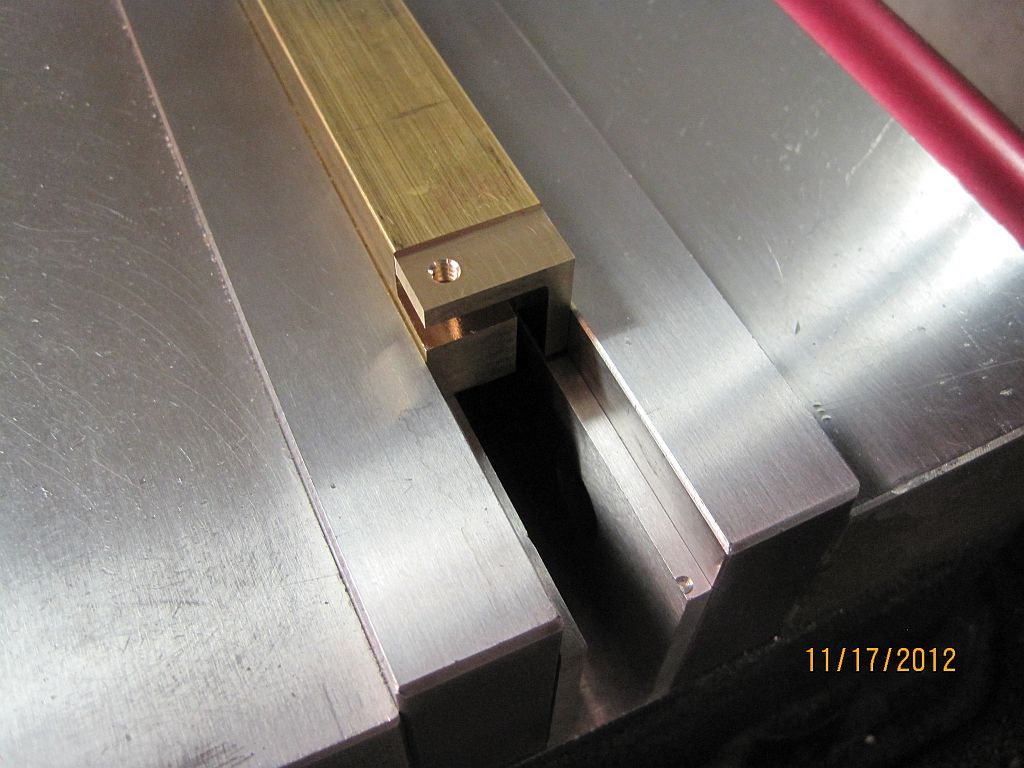

The sides of the valve lifter mounting surface are brought to the proper thickness.

Standing the block vertical the 3rd face of the valve lifter surface is machined.

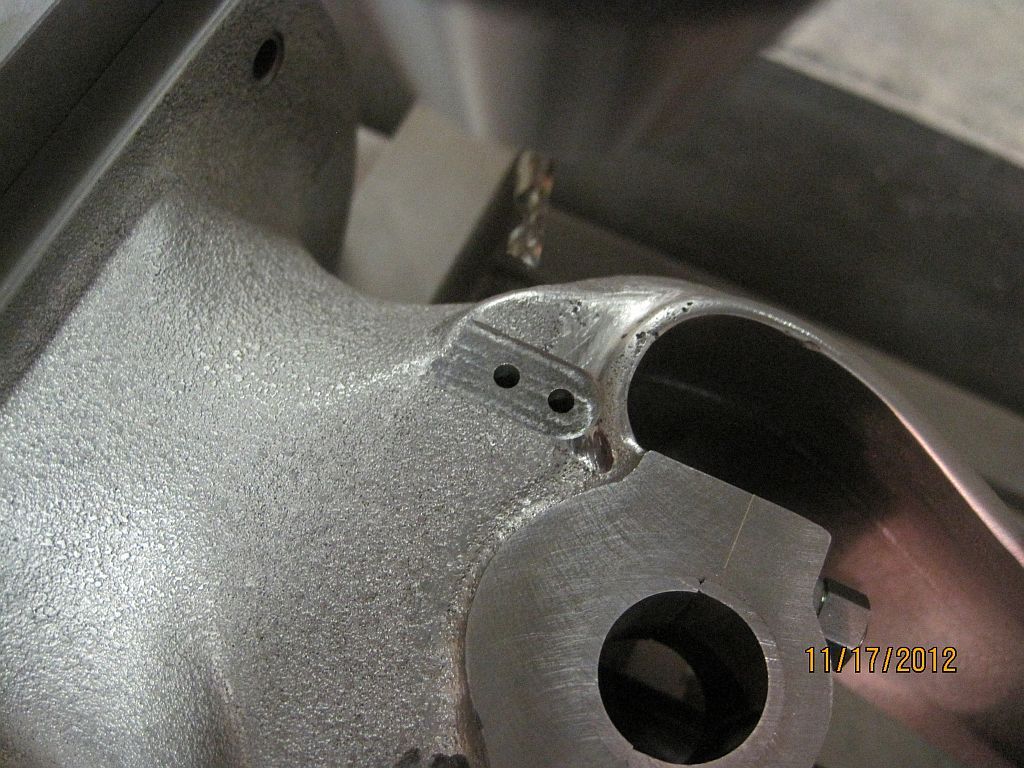

Also at this time the length of the follower shoe housing is machined as well as the top end of the arm. This length is measured from the top of the follower shoe housing.

Laying the block down with the swing arm upside down; the bottom pivot area is machined flat.

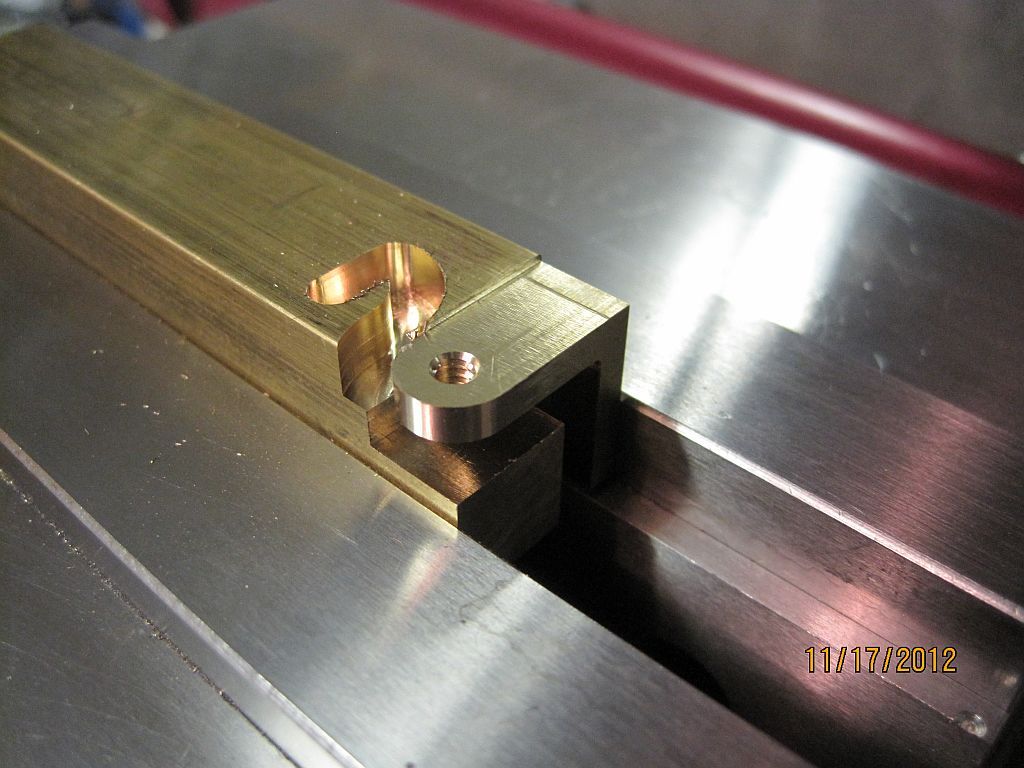

The follower shoe housing is centered up, spotted, drilled and reamed.

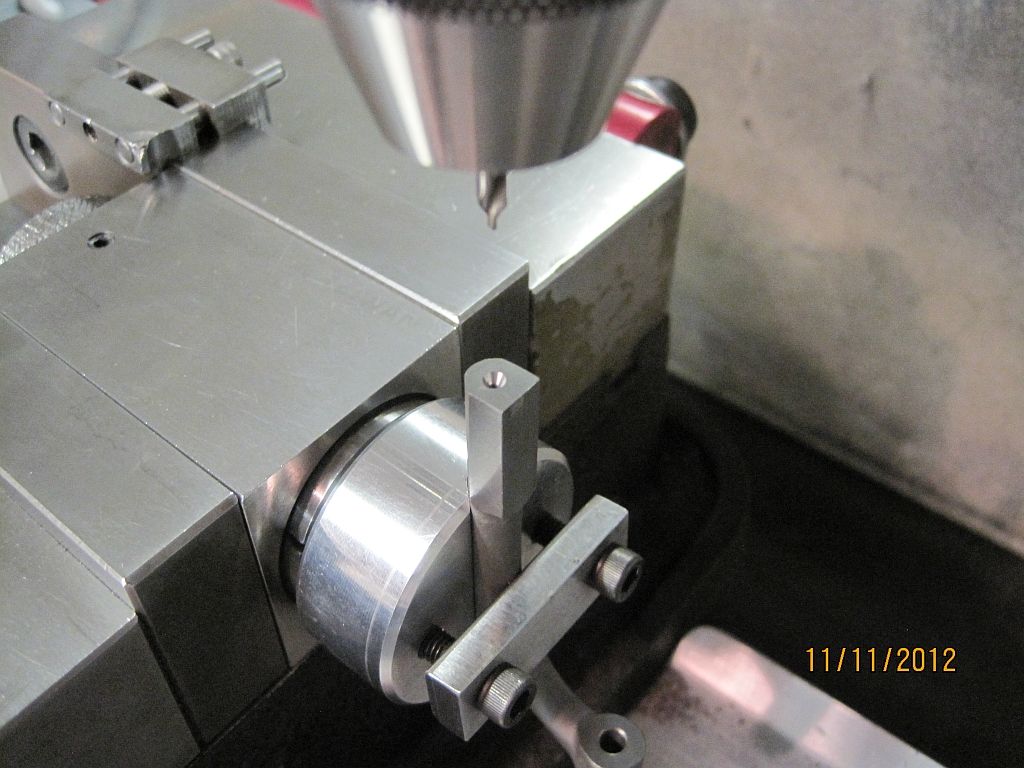

The upper and lower pivots are centered up and center drilled.

The last operation is to machine the round area on the top above where the valve lifter will mount.

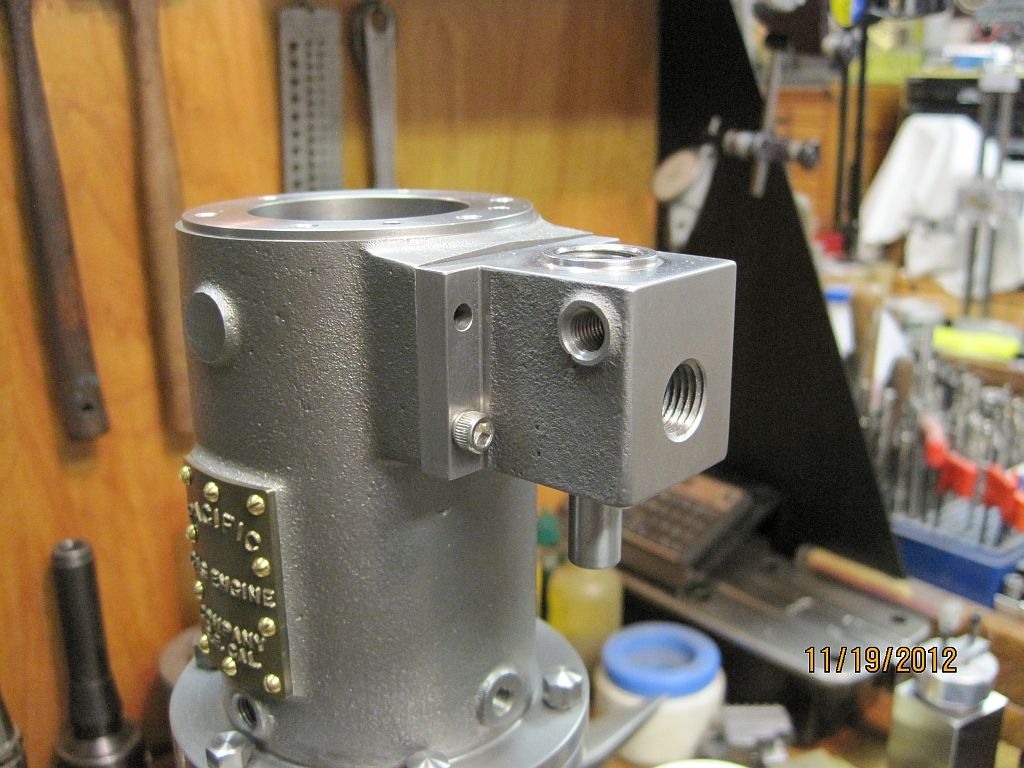

Here is the finished swing arm; the pivot hole for that valve lifter needs to be added but not until a few more parts are completed.

Thanks for checking in.

Dave